If you're looking to achieve that perfect ultra-fine mist, look no further than air atomizing spray nozzles. These tiny marvels utilize compressed air to break down liquids into minuscule droplets, creating a fog-like consistency ideal for a wide range of applications. But with so many nozzles on the market, choosing the right one can be tricky. Fear not, mist-maker extraordinaire! This blog post will be your guide to navigating the world of air atomizing nozzles.

What are Air Atomizing Nozzles?

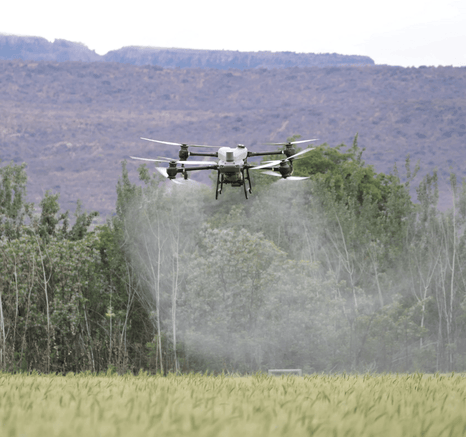

Unlike their pressure-powered counterparts, air atomizing nozzles rely on compressed air, not liquid pressure, to create a mist. This air mixes with the liquid inside the nozzle, shearing it into tiny droplets. The result? A weightless, even mist perfect for tasks like:

- Humidification: Add moisture to dry air in homes, greenhouses, and industrial settings.

- Cooling: Control temperature in manufacturing processes, gas turbines, and data centers.

- Coating: Apply thin, uniform layers of paint, adhesives, or other liquids.

- Lubrication: Deliver precise amounts of lubricant to machinery with minimal mess.

- Dust suppression: Control dust in mines, quarries, and construction sites.

Choosing the Right Nozzle:

Now that you know the magic of air atomizing nozzles, let's delve into selecting the perfect one for your needs. Here are some key factors to consider:

- Flow Rate: How much liquid do you need to atomize per minute? Match the nozzle's flow rate to your requirements.

- Spray Pattern: Do you need a wide fan, a narrow cone, or something in between? Choose a pattern that suits your application's geometry.

- Liquid Viscosity: Are you working with water, paint, or something thicker? Select a nozzle compatible with your liquid's viscosity.

- Mixing Type: Internal mixing nozzles combine air and liquid within the nozzle, while external mixing nozzles do so outside. Consider factors like space constraints and fluid compatibility.

- Material: Stainless steel is a popular choice for durability and corrosion resistance, while plastics offer affordability and lighter weight.

Pro Tips for Misting Mastery:

- Mind the Pressure: Use the correct air pressure for your chosen nozzle to achieve the desired droplet size and flow rate. Too much pressure can lead to larger droplets and reduced efficiency.

- Filter Power: Employ filters to remove impurities from your liquid and compressed air, preventing nozzle clogs and ensuring consistent performance.

- Maintenance Matters: Regularly clean your nozzle following the manufacturer's instructions to prevent buildup and ensure optimal performance.

Misting Forward:

With the right air atomizing nozzle and a little know-how, you can unlock a world of misting possibilities. From creating a cool, refreshing atmosphere to achieving precise industrial coatings, these versatile tools offer a unique and effective way to control liquids. So, dive into the world of air atomization and discover the perfect mist for your needs!