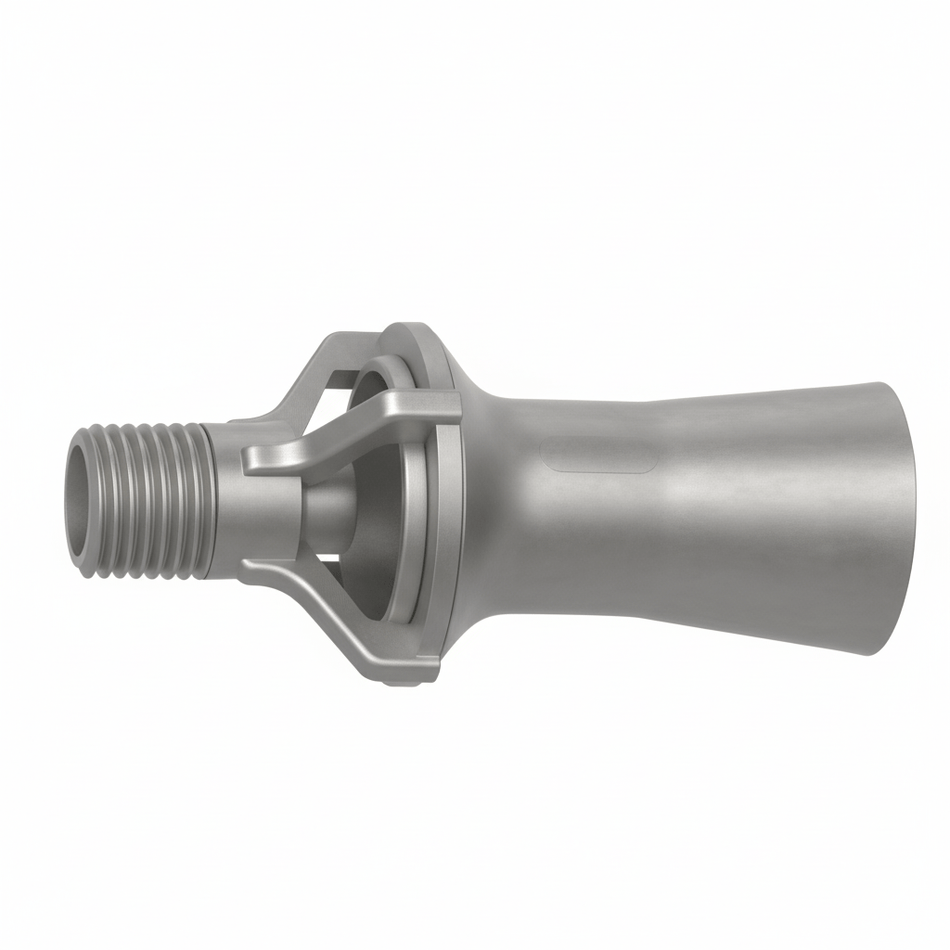

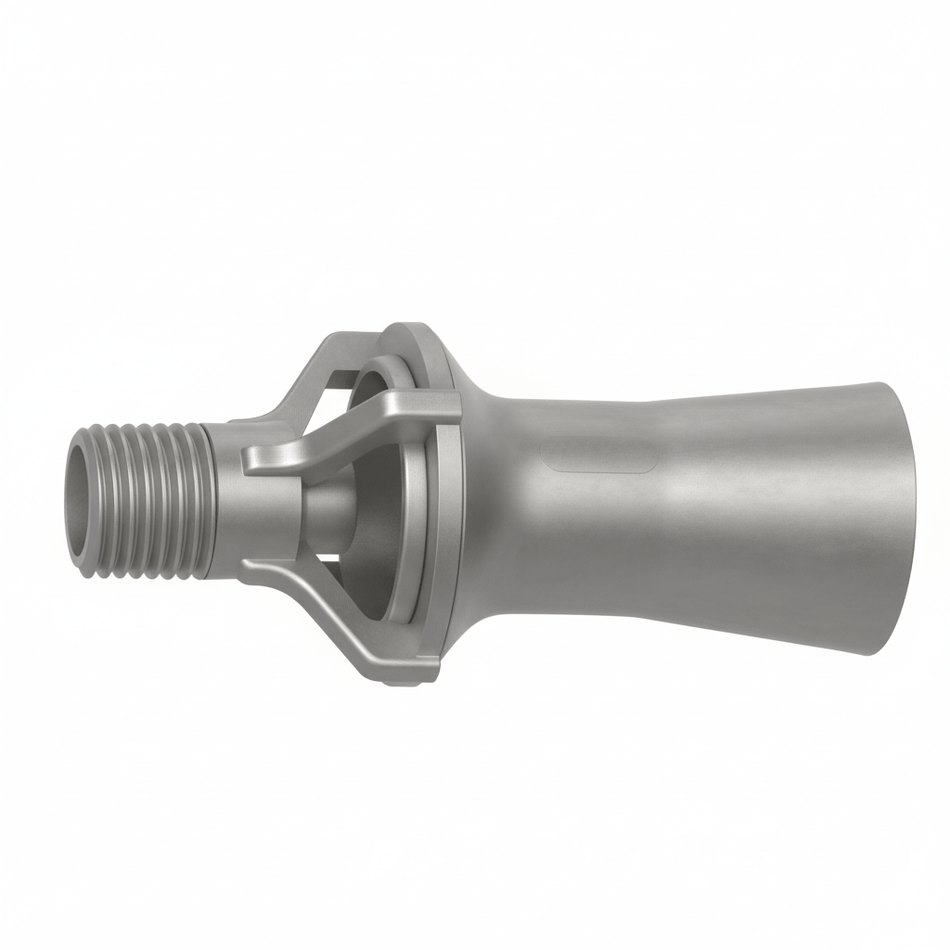

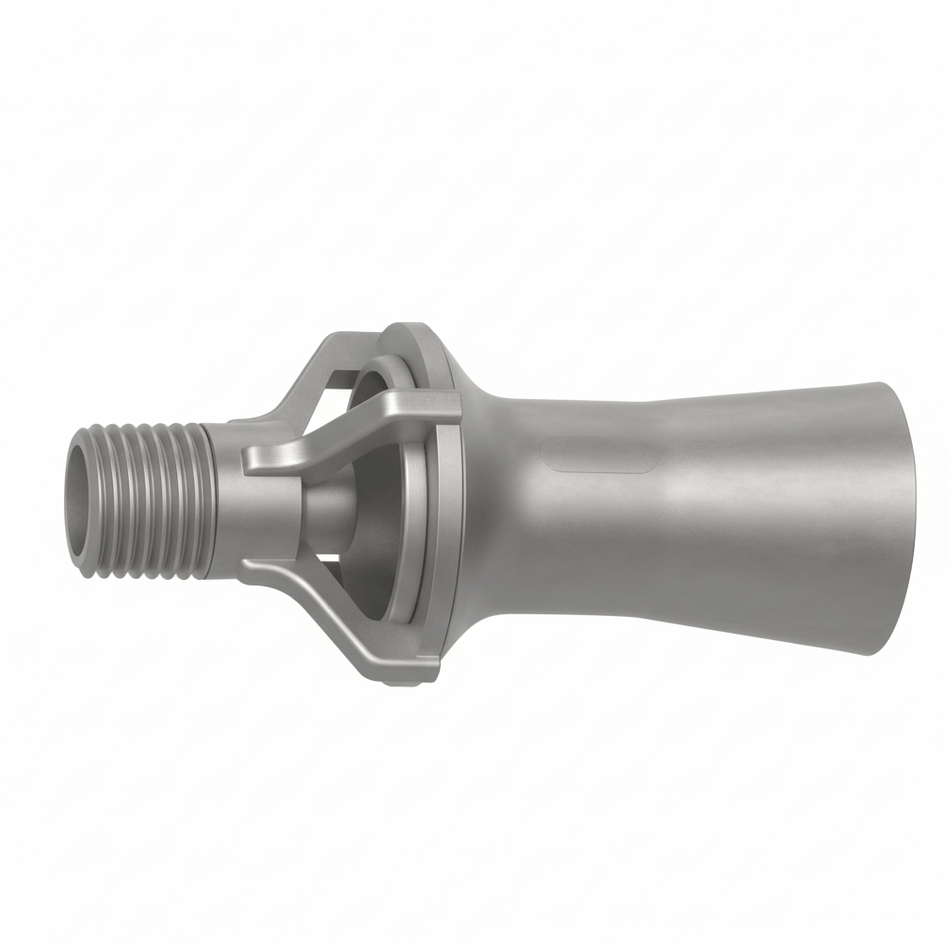

Eductor Nozzles Series

Eductor Nozzles

Eductor nozzles use venturi action to entrain and multiply flow—ideal for foam generation, mixing, and chemical injection applications.

Spray Pattern

Eductor

Available SKUs

8 Products

Quality

Industrial Grade

Shipping

Ships Fast

8 Products

Eductor Nozzles

Guide

Eductor Nozzles: Overview & Selection Tips

Eductor nozzles use venturi action to entrain and multiply flow—ideal for foam generation, mixing, and chemical injection applications.

Popular series in this family: NPK2.

Common applications

- Foam generation

- Chemical injection

- Tank agitation

- Mixing & blending

- Cleaning systems

How to choose Eductor Nozzles

- Start with required flow per nozzle and your operating pressure at the nozzle.

- Select spray angle to hit the target width at your mounting distance (spray width ≈ 2 × distance × tan(angle ÷ 2)).

- Choose the nozzle style and series that fits your mounting, clog-resistance, and droplet/impact goals.

- Confirm inlet size (NPT) and select materials compatible with chemicals, temperature, and wear.

- Use strainers/filters where water quality or debris can cause plugging.

Related application collections

Foam Control & Suppression | Cleaning & Washing | Tank Cleaning Spray Nozzles | Coating & Surface Treatment

Features & Benefits

What makes the Eductor Nozzles series stand out

How to choose

How to choose the right Eductor Nozzles nozzle for your application

Frequently Asked Questions

Common questions about the Eductor Nozzles series

What is an eductor nozzle?

An eductor nozzle, also called a jet pump, uses a pressurized motive stream to create suction and entrain a secondary fluid through a venturi. With no moving parts, eductors are a reliable option for mixing, circulation, and fluid transfer.

How does an eductor create suction?

Motive liquid accelerates through the nozzle and creates a low-pressure zone that draws in secondary fluid. The streams mix and discharge through a diffuser, creating circulation and mixing in the tank or line.

What are common applications for eductor nozzles?

Typical uses include tank mixing and agitation, chemical blending, recirculation, liquid transfer, sump emptying, and process circulation where mechanical mixers are impractical.

Which NozzlePro series covers eductor nozzles?

NozzlePro NPK2 is our eductor nozzle family. Select by motive pressure, suction requirements, connection size, and material compatibility.

What materials are available for NozzlePro eductor nozzles?

Common options include 316L Stainless Steel, Polypropylene. Choose based on chemical compatibility, temperature, and corrosion requirements.

What inlet sizes are available for eductor nozzles?

NPK2 eductor nozzles are offered in sizes such as 1/4", 3/8", 1/2", 3/4" NPT, depending on model. Match the size to your piping and the required flow rate.

Need Help Selecting the Right Nozzle?

Our engineering team is ready to help you find the perfect spray solution for your application.