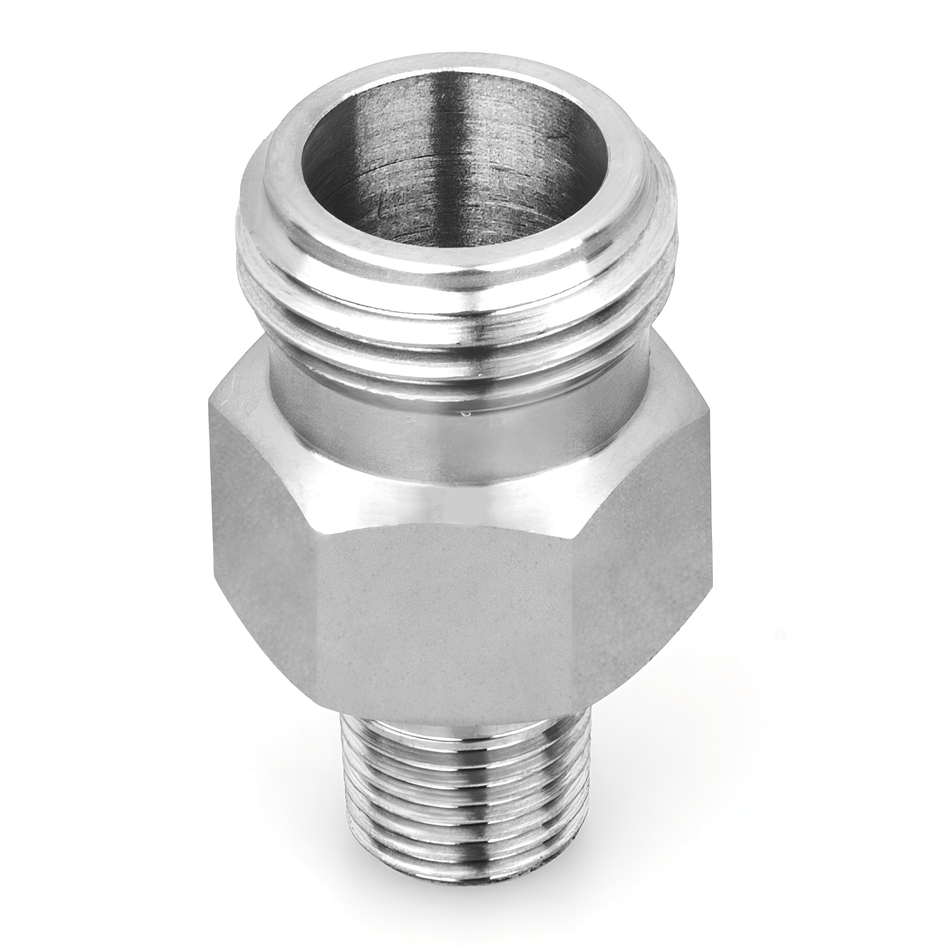

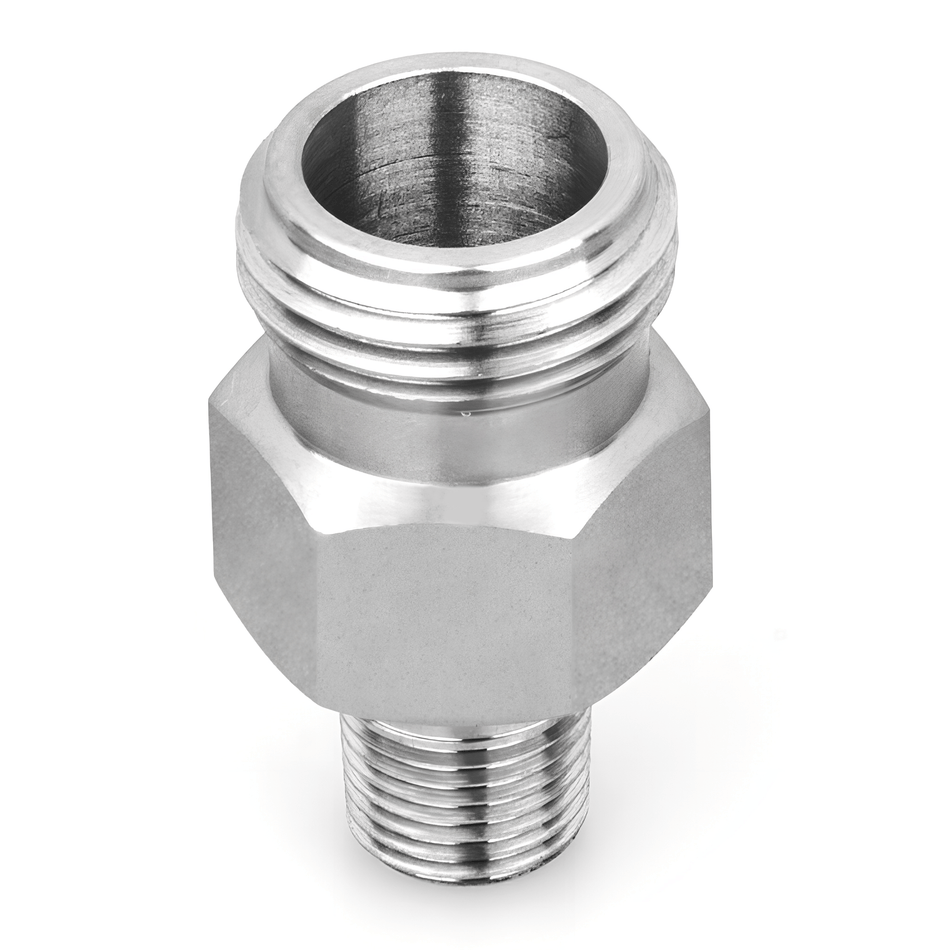

ProJet 3X Modular Unit Assembly Series

ProJet 3X Modular Unit Assembly

ProJet 3X modular assemblies let you mix bodies, caps, strainers, and tips for fast maintenance and flexible spray pattern changes.

Spray Pattern

Assemblies

Available SKUs

873 Products

Quality

Industrial Grade

Shipping

Ships Fast

873 Products

ProJet 3X Modular Unit Assembly

Guide

ProJet 3X Modular Unit Assembly: Overview & Selection Tips

ProJet 3X modular assemblies let you mix bodies, caps, strainers, and tips for fast maintenance and flexible spray pattern changes.

Build components

- Bodies and connections (NPT, quick-connect, modular)

- Tips/caps for the desired spray pattern and performance

- Strainers/filtration components where plugging is a concern

- Seals and materials for chemical and temperature compatibility

- Mounting hardware and accessories

How to choose an assembly

- Define the spray requirement (flow, pressure, spray angle/coverage).

- Select a platform that fits your maintenance needs (threaded, quick-connect, modular).

- Choose compatible components and confirm materials/seals.

- Standardize assemblies across equipment to simplify spares and service.

Related application collections

Cleaning & Washing | Coating & Surface Treatment | Cooling & Quenching | Pressure Washing Spray Nozzles

Features & Benefits

What makes the ProJet 3X Modular Unit Assembly series stand out

Build checklist

How to choose the right ProJet 3X Modular Unit Assembly nozzle for your application

Frequently Asked Questions

Common questions about the ProJet 3X Modular Unit Assembly series

What spray nozzles work best for ProJet 3X Modular Unit Assembly?

Selection depends on spray pattern needed (flat, full cone, hollow cone), flow rate, pressure, materials, and connections. NozzlePro offers complete ranges with appropriate materials and certifications.

What materials are recommended for ProJet 3X Modular Unit Assembly?

316L stainless steel for corrosion resistance and food safety, polypropylene for chemical resistance, brass for general duty. Select based on chemical exposure, temperature, and sanitary requirements.

How do I select the right spray pattern?

Flat fan for uniform coating and rinsing, full cone for complete coverage and cooling, hollow cone for fine atomization, solid stream for high-impact cleaning. Consider overlap requirements for spray bars.

What certifications matter for ProJet 3X Modular Unit Assembly?

Depending on application: FDA compliance, 3-A Sanitary Standards, NSF listing, ATEX rating for hazardous areas, and material certifications. Requirements vary by industry and regulatory environment.

What flow rates and pressures are typical?

Cleaning typically uses 40–100 PSI with flows matched to coverage needs. Cooling may use lower pressures for finer droplets. High-pressure cleaning runs 500–4000 PSI. Size nozzles for your specific needs.

How do I get help selecting nozzles?

NozzlePro's technical team can help with selection. Share your spray pattern, flow rate, pressure, chemical compatibility, temperature, and regulatory requirements for recommendations.

Need Help Selecting the Right Nozzle?

Our engineering team is ready to help you find the perfect spray solution for your application.