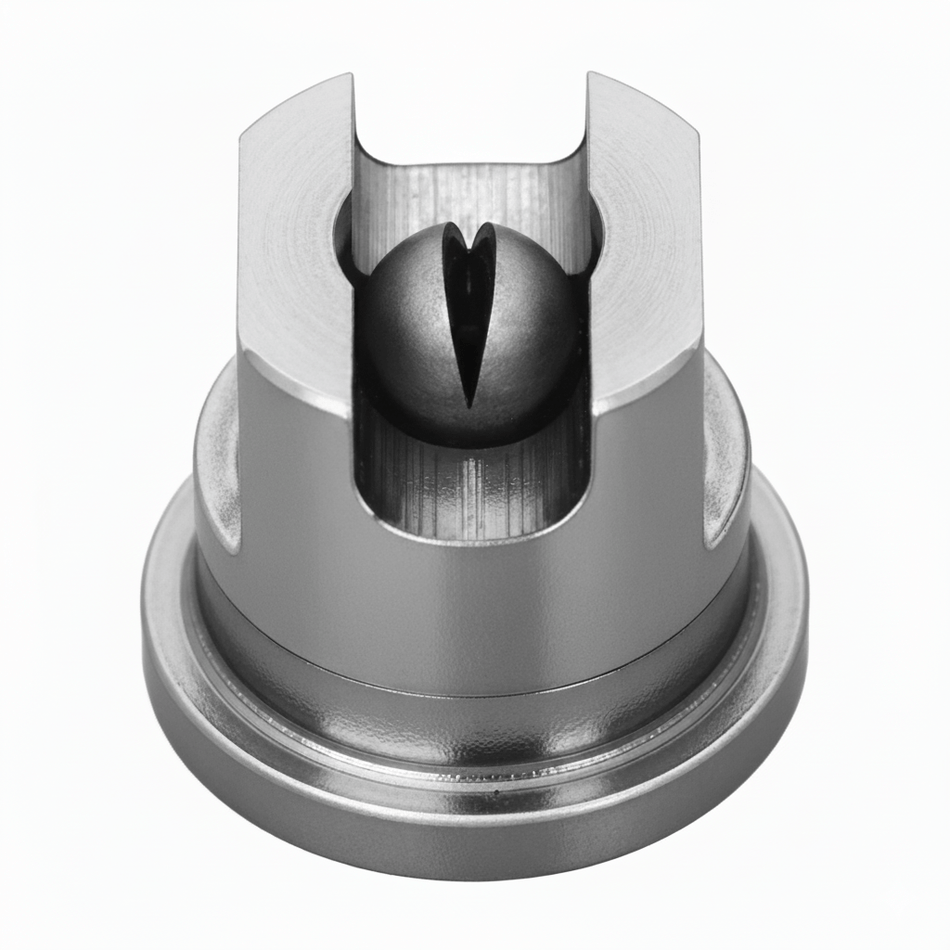

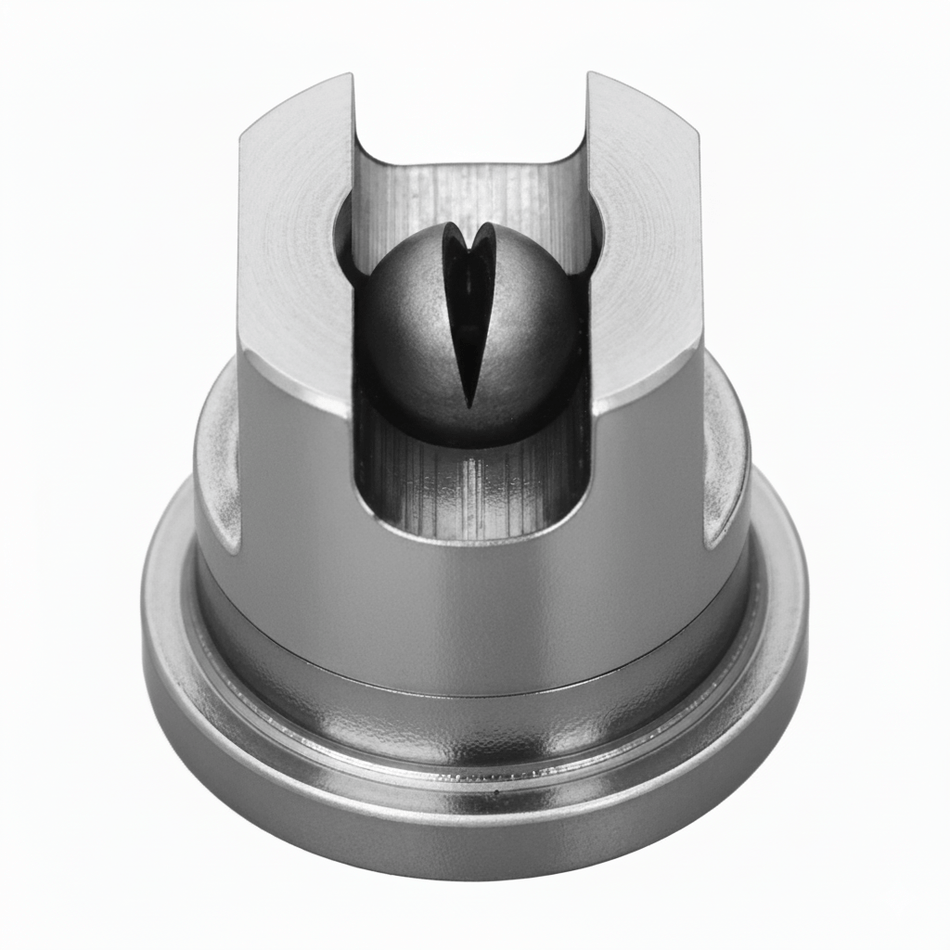

Tungsten Carbide Nozzles Series

Tungsten Carbide Nozzles

Tungsten carbide nozzles and inserts improve wear resistance for abrasive or high-pressure service—helping maintain consistent flow longer.

Spray Pattern

Wear Resistant

Available SKUs

120 Products

Quality

Industrial Grade

Shipping

Ships Fast

120 Products

Tungsten Carbide Nozzles

Guide

Tungsten Carbide Nozzles: Overview & Selection Tips

Tungsten carbide nozzles and inserts improve wear resistance for abrasive or high-pressure service—helping maintain consistent flow longer.

Popular series in this family: NP-TC, NPJET.

Common applications

- Abrasive service

- High-pressure cleaning

- Descaling

- Mining & wear applications

- Long-life jetting

How to choose Tungsten Carbide Nozzles

- Start with required flow per nozzle and your operating pressure at the nozzle.

- Select spray angle to hit the target width at your mounting distance (spray width ≈ 2 × distance × tan(angle ÷ 2)).

- Choose the nozzle style and series that fits your mounting, clog-resistance, and droplet/impact goals.

- Confirm inlet size (NPT) and select materials compatible with chemicals, temperature, and wear.

- Use strainers/filters where water quality or debris can cause plugging.

Related application collections

Pressure Washing Spray Nozzles | Cleaning & Washing | Cooling & Quenching | Tank Cleaning Spray Nozzles

Features & Benefits

What makes the Tungsten Carbide Nozzles series stand out

How to choose

How to choose the right Tungsten Carbide Nozzles nozzle for your application

Frequently Asked Questions

Common questions about the Tungsten Carbide Nozzles series

What is the Tungsten Carbide Nozzles series used for?

The Tungsten Carbide Nozzles series supports industrial spray applications with selection based on flow rate, spray pattern, operating pressure, and material compatibility—from cleaning and cooling to coating and process control.

What spray patterns does Tungsten Carbide Nozzles produce?

Pattern options vary by model. Check product specifications for available spray angles and patterns. NozzlePro can help match patterns to your application requirements.

What materials are available for Tungsten Carbide Nozzles?

Tungsten Carbide Nozzles are available in brass, 316L stainless steel, polypropylene, and other materials depending on model. Select based on chemical compatibility, temperature, and wear requirements.

How do I size Tungsten Carbide Nozzles?

Select based on required flow rate at your operating pressure, needed coverage, connection size, and material compatibility. Review capacity tables and verify performance meets your requirements.

What connection sizes are available?

Typically NPT threads from 1/8" to 1" or larger depending on flow capacity. BSPT and metric threads may also be available. Match to your piping and flow requirements.

What series are similar to Tungsten Carbide Nozzles?

Related options include NP-TC, NPJET—compare by pattern, capacity range, and connection type.

Need Help Selecting the Right Nozzle?

Our engineering team is ready to help you find the perfect spray solution for your application.