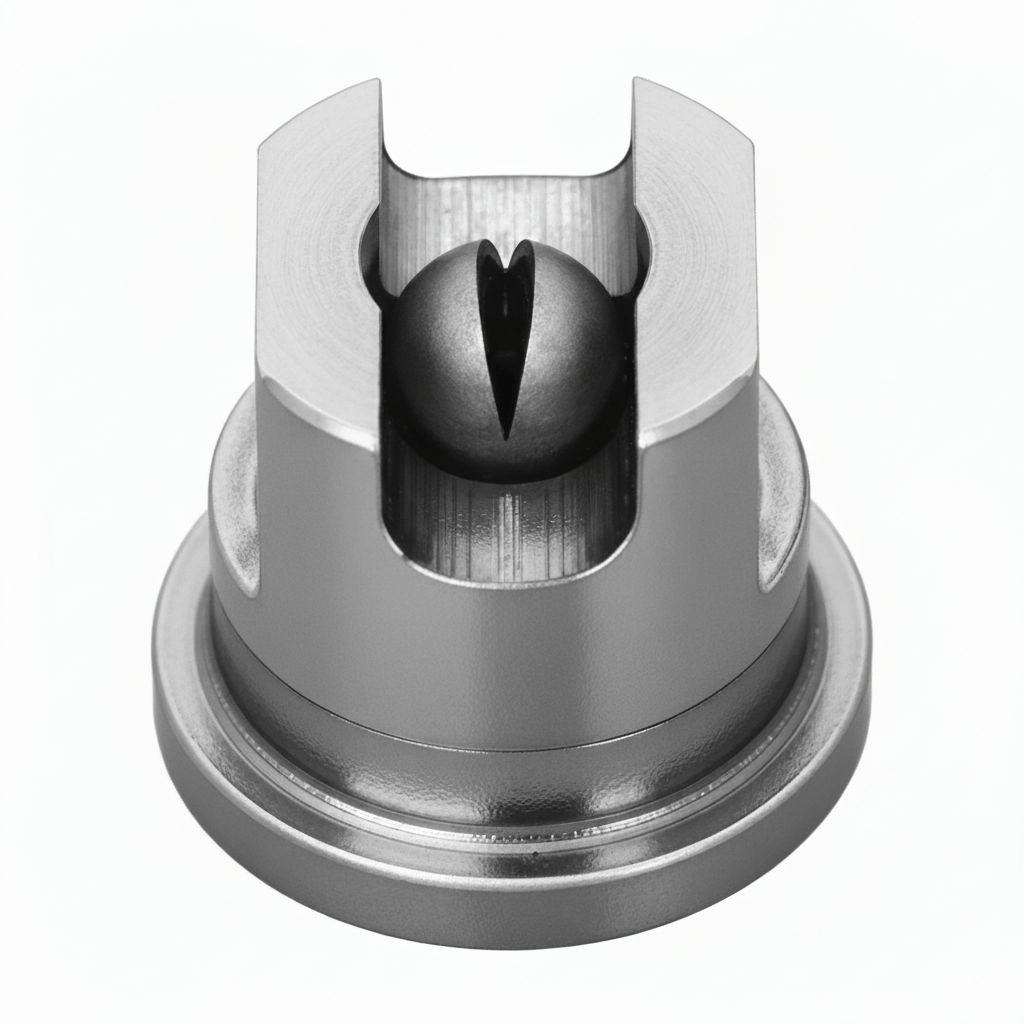

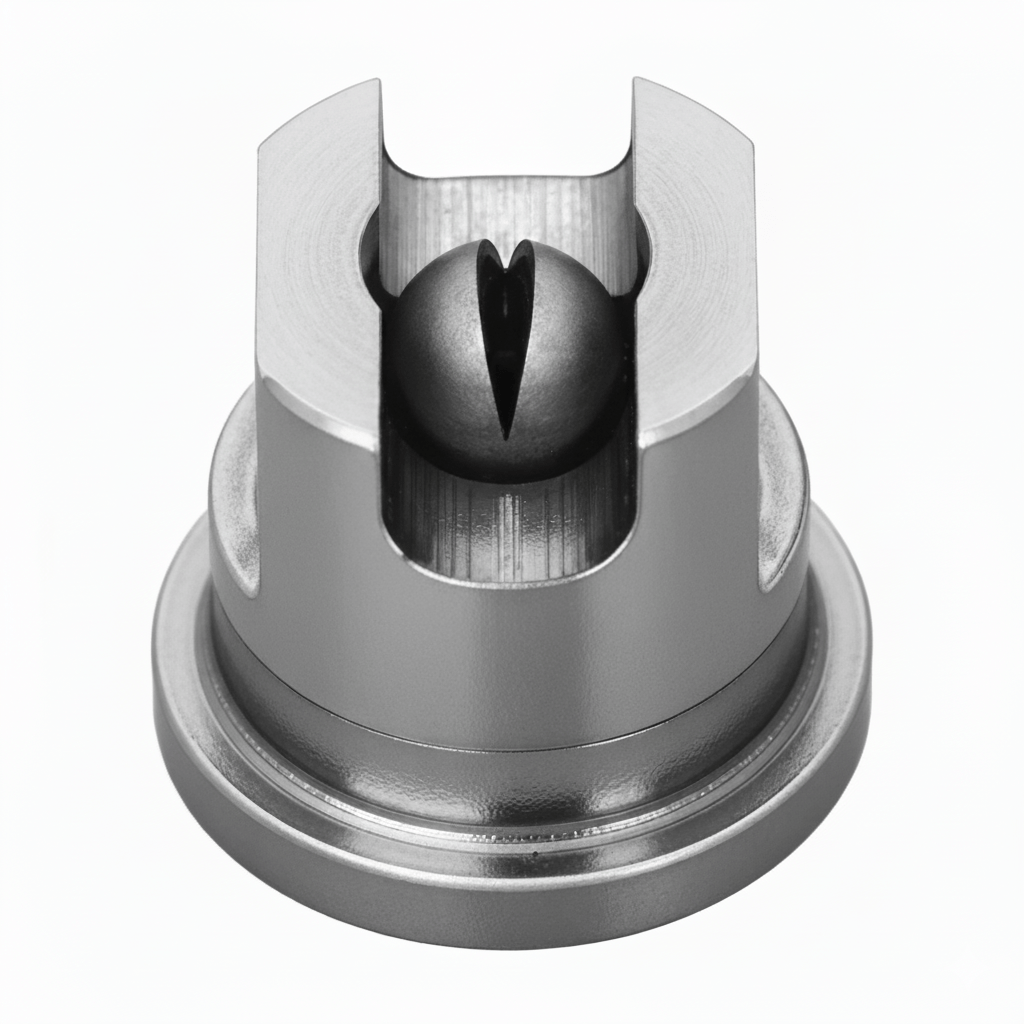

Product Parameters

| Product Family | High Pressure |

|---|---|

| Product Series | NP-TC |

| Spray Pattern Type | FLAT |

| Capacity Size | 10 |

| Material Composition Filter | Tungsten carbide insert |

| Spray Angle at Rated Pressure (PSI) | 25 |

Description

Product Overview

When food & beverage crews manage coating & surface treatment, the NP2510-TC lets each production technician achieve consistent coverage through its precisely engineered tungsten carbide insert. Operators install the nozzle to deliver a uniform spray pattern that withstands corrosive environments, maintaining system integrity over extended production runs. The nozzle's high-pressure capacity ensures thorough application while reducing downtime caused by wear. As a result, facilities can measure improved operational efficiency and longer service intervals with the NP2510-TC.

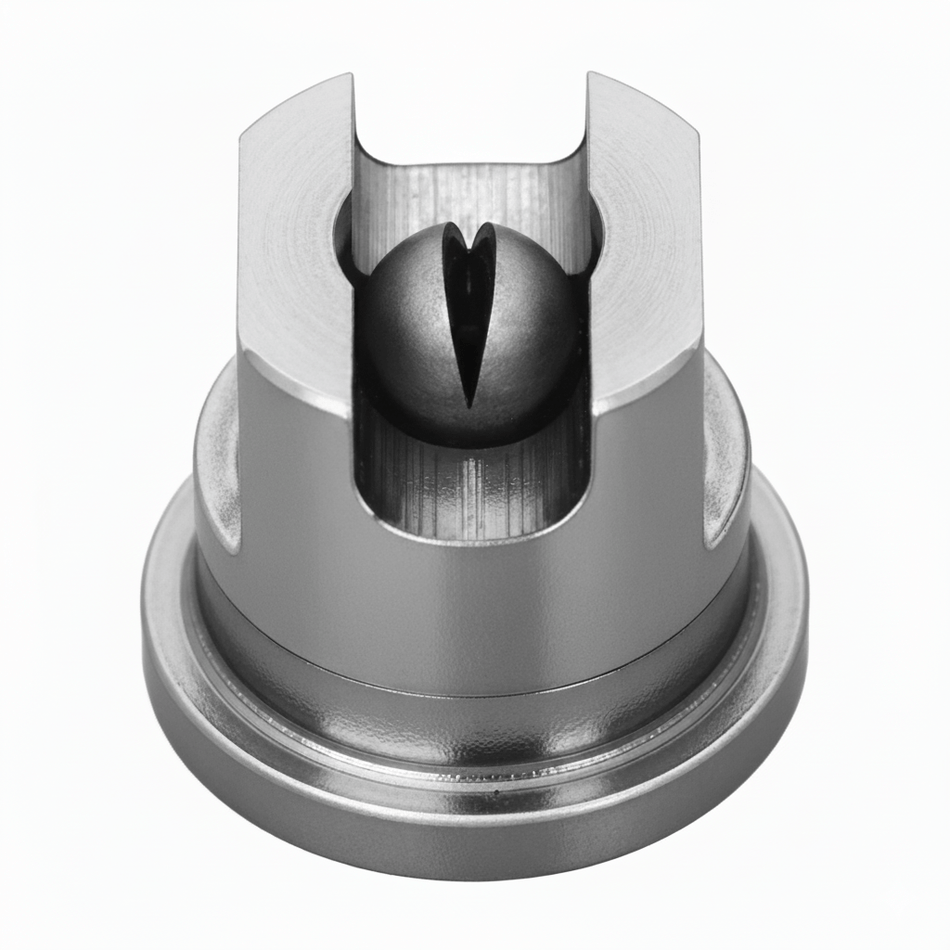

Applications

In cleaning & washing operations, the NP2510-TC facilitates effective removal of residues without compromising equipment surfaces, optimizing sanitation cycles. Its role in coating & surface treatment supports even material distribution, which enhances adhesion and finish quality across varied substrates.

Industries

Sectors such as automotive, mining, and steel & metals rely on the NP2510-TC for its durability and spray consistency under demanding conditions. The building materials and food & beverage industries also benefit from its resistance to corrosion and ability to maintain performance in high-pressure environments.