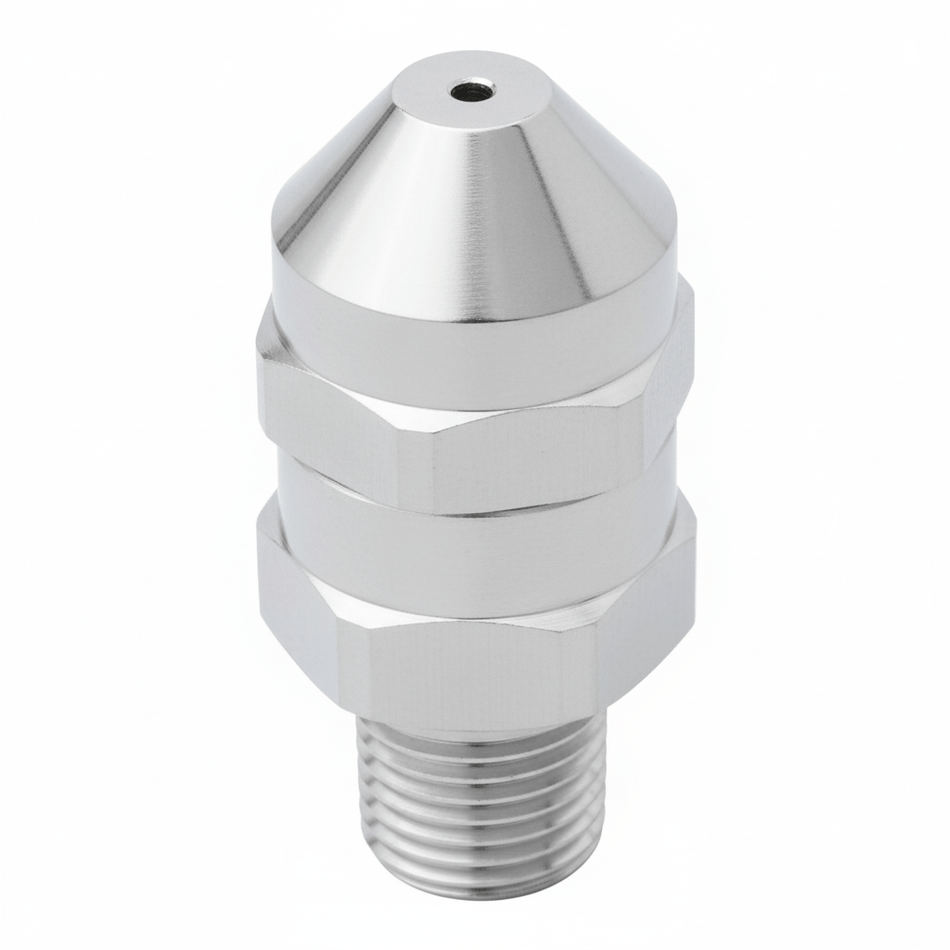

Full Cone Spray Nozzles Series

Full Cone Spray Nozzles

Full Cone Spray Nozzles full-cone nozzles provide uniform distribution for rinsing, cooling, and process spraying with selectable angles and capacities.

Spray Pattern

Full Cone

Available SKUs

877 Products

Quality

Industrial Grade

Shipping

Ships Fast

877 Products

Full Cone Spray Nozzles

Guide

Full Cone Spray Nozzles: Overview & Selection Tips

Full Cone Spray Nozzles full-cone nozzles provide uniform distribution for rinsing, cooling, and process spraying with selectable angles and capacities.

Popular series in this family: NPHH, NPGG, NPGG-30, NPGG-15, NPMGA, NPFGA, NPMFP, NPHSJ.

Common applications

- Cooling

- Washing

- Dust suppression

- Quenching

- Fire protection

How to choose Full Cone Spray Nozzles

- Start with required flow per nozzle and your operating pressure at the nozzle.

- Select spray angle to hit the target width at your mounting distance (spray width ≈ 2 × distance × tan(angle ÷ 2)).

- Choose the nozzle style and series that fits your mounting, clog-resistance, and droplet/impact goals.

- Confirm inlet size (NPT) and select materials compatible with chemicals, temperature, and wear.

- Use strainers/filters where water quality or debris can cause plugging.

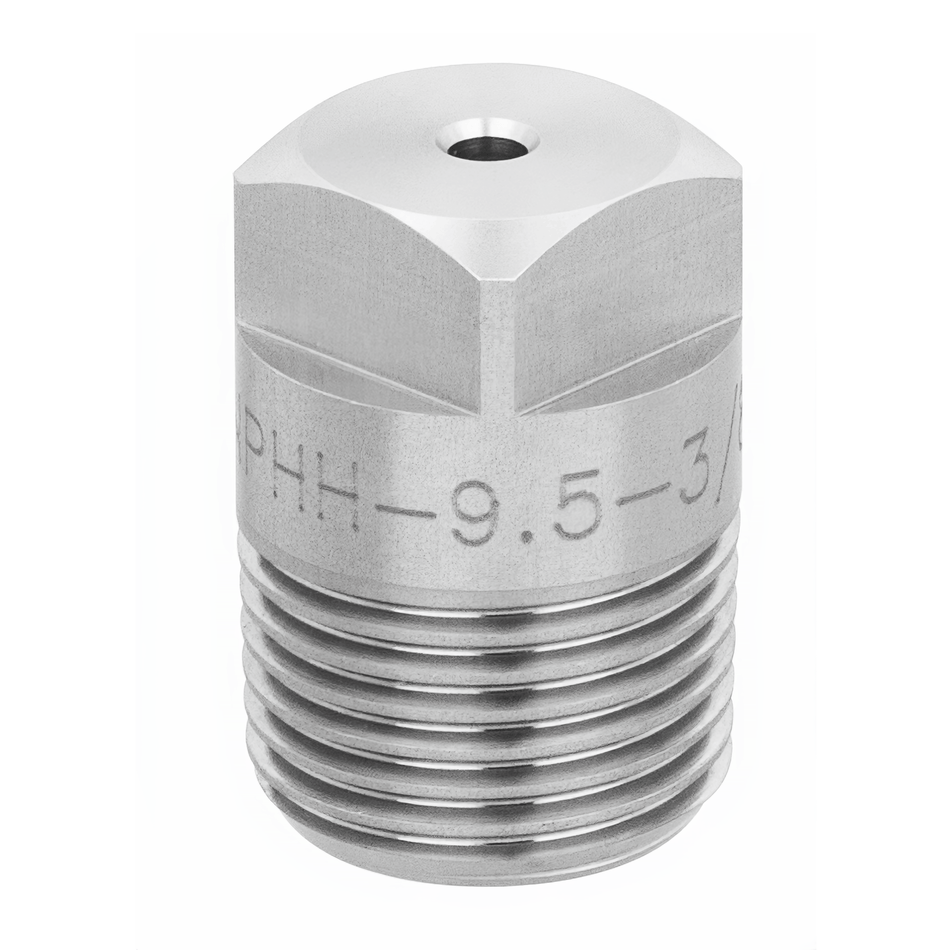

Part numbering tip

Many nozzle families embed spray angle and capacity in the part number (for example, “80-15” can indicate an 80° spray angle and 1.5 GPM at the family’s reference pressure). Always verify flow at your operating pressure.

Related application collections

Cooling & Quenching | Cleaning & Washing | Foam Control & Suppression

Features & Benefits

What makes the Full Cone Spray Nozzles series stand out

How to choose

How to choose the right Full Cone Spray Nozzles nozzle for your application

Frequently Asked Questions

Common questions about the Full Cone Spray Nozzles series

What is the Full Cone Spray Nozzles series used for?

Full Cone Spray Nozzles full cone nozzles produce a solid circular pattern with uniform coverage from center to edge. They're used for washing, cooling, dust suppression, fire protection, and tank filling where complete coverage matters.

How do I calculate Full Cone Spray Nozzles coverage diameter?

Use: Diameter = 2 × Spray Distance × tan(Spray Angle ÷ 2). For overlapping installations, space nozzles so patterns overlap by 25–30% to ensure uniform distribution across the target area.

What's the difference between vane-style and spiral full cone nozzles?

Vane-style nozzles offer more precise distribution but can clog with debris. Spiral designs (like NPHSJ) have larger free passage and resist clogging—better for dirty water, recycled fluids, or slurries.

What materials are available for Full Cone Spray Nozzles?

Full Cone Spray Nozzles are available in brass, 316L stainless steel, polypropylene, and PVDF. Select stainless for food/beverage applications; polypropylene or PVDF for chemical resistance.

How do I prevent clogging in Full Cone Spray Nozzles?

Install upstream strainers with mesh finer than the nozzle orifice. Choose larger orifice sizes when possible. For dirty liquids, consider spiral full cone designs with their larger free passage.

What series are similar to Full Cone Spray Nozzles?

Related full cone options include NPHH, NPGG, NPGG-30, NPGG-15, NPMGA, NPFGA, NPMFP, NPHSJ—compare by spray angle, capacity, and clog resistance.

Need Help Selecting the Right Nozzle?

Our engineering team is ready to help you find the perfect spray solution for your application.