When your spray system starts acting up, producing uneven coats, dripping when it shouldn't, or wasting compressed air, it's usually the nozzle trying to tell you something. Air atomizing nozzles are workhorses in countless industrial applications, but like any precision equipment, they need the right care to keep performing at their best.

Key Takeaways

-

Air atomizing nozzles rely on a precise balance between air pressure and liquid flow to create fine, consistent spray patterns

-

Most spray problems stem from just a few culprits: clogged orifices, incorrect air-to-liquid ratios, worn internal parts, or contaminated fluids

-

Regular cleaning and preventive maintenance can prevent 80% of common nozzle failures and extend equipment life significantly

- Knowing when to repair versus replace a nozzle can save you both time and money in the long run

What Are Air Atomizing Nozzles and Why Do They Matter?

Air atomizing nozzles are precision devices that use compressed air to break liquid into fine droplets. Unlike simpler spray nozzle types that rely purely on liquid pressure, these nozzles give you incredible control over droplet size and spray characteristics. That control matters tremendously when you're coating pharmaceutical tablets, applying lubricant to metal parts, humidifying a cleanroom, or dosing chemicals with pinpoint accuracy.

In industries like food processing, pharmaceuticals, automotive coating, and precision manufacturing, the difference between good atomization and poor atomization can mean the difference between a perfect product and expensive waste.

How Air Atomizing Nozzles Actually Work

Before we dive into troubleshooting, let's quickly cover what's happening inside these devices. An air atomizing nozzle typically consists of several key components: an air cap, a liquid orifice, a mixing chamber, and often a needle or spray tip that controls flow.

Compressed air and liquid meet either inside the nozzle body (internal mix) or just outside it (external mix). The high-velocity air breaks the liquid stream into tiny droplets through shear force. The ratio between air pressure and liquid pressure called the air-to-liquid ratio or ALR, determines how fine those droplets become.

Internal mix nozzles combine air and liquid inside a chamber before releasing the atomized spray. They create very fine droplets and work great for low-viscosity liquids, but they're more prone to clogging if your fluid isn't perfectly clean.

External mix nozzles keep the air and liquid separate until they meet just outside the spray nozzle tips. They handle thicker liquids better and are easier to clean, but they typically use more air.

The Most Common Problems You'll Encounter

1. Irregular or Inconsistent Droplet Size

You're expecting a fine mist, but instead you're getting a mix of tiny droplets and big splotches. This inconsistency shows up as overspray in some areas and inadequate coverage in others.

What's likely happening: Your air-to-liquid ratio is off, the air cap has debris blocking some holes, or the liquid orifice has started to wear. Sometimes you'll see this with industrial spray nozzles that have been running the same fluid for months without proper cleaning.

2. Poor or Incomplete Atomization

The spray looks more like a weak stream than a proper mist. You might see wet spots, dripping, or a spray pattern that just doesn't look right.

Common causes: Insufficient air pressure tops the list. If your compressor isn't keeping up or there's a pressure drop in the line, the nozzle can't generate enough energy to properly break up the liquid. Damaged tips or blocked internal passages also prevent proper atomization.

3. Clogging or Partial Blockage

This is probably the most frequent issue maintenance teams face. The nozzle works fine one day, then gradually or suddenly starts producing an uneven pattern.

What's going on: Contaminated fluid is the usual suspect. Even microscopic particles can lodge in the precise orifices of an air nozzle. If you're also working with misting nozzles in other parts of your facility, you've probably seen similar issues. Residue buildup from the liquid itself can also accumulate over time.

4. Fluctuating Spray Pattern

The pattern looks good, then suddenly changes, then goes back to normal. It's unpredictable and frustrating.

Root causes: Inconsistent air supply from the compressor, pressure drops during peak usage times, or internal parts that have worn just enough to cause intermittent problems.

5. Leaking or Dripping Nozzles

When the spray should stop, it doesn't. You get drips, dribbles, or a continuous leak.

Why it happens: The needle that controls shut-off has worn or become damaged, internal seals have degraded, or the nozzle isn't closing completely. This is especially common in spray systems that cycle on and off frequently.

6. Excessive Air Consumption

Your compressed air bills are climbing, or you're noticing the compressor running more than usual.

Possible issues: A mechanical fault in the nozzle, the wrong nozzle selected for the job, or a worn air cap that's requiring more pressure to achieve the same atomization quality.

7. Spray Direction Misalignment

The nozzle is pointing where it should, but the spray pattern goes somewhere else.

Usually caused by: Incorrect installation, vibration loosening the mounting over time, or fittings that weren't tightened properly during the last maintenance cycle.

Step-by-Step Troubleshooting Guide

Step 1: Check Air Pressure and Air Quality

Start with the basics. Grab a pressure gauge and verify the air pressure at the nozzle, not just at the compressor. Pressure drops in the line are real, especially if you're running multiple tools.

Most air atomizing nozzles work best between 20-90 PSI, but always check your manufacturer's specifications. Just as important is air quality. Moisture and oil in compressed air can cause problems, from contaminating your spray to corroding internal components.

Step 2: Inspect and Clean the Nozzle

Power down and depressurize everything first. Remove the nozzle and examine it closely. Look for obvious debris, buildup, or damage.

Never use metal picks, wires, or anything that could scratch the precision orifices. Even a tiny scratch changes the flow characteristics permanently. Instead, soak the nozzle in an appropriate solvent for your fluid type, then use soft bristle brushes or compressed air to clear passages.

Step 3: Verify the Air-to-Liquid Ratio

The ALR is your magic number. Too much air relative to liquid, and you'll waste compressed air while potentially getting over-atomization. Too little air, and you won't get proper atomization at all.

A typical starting point is around 1:1 by volume, but this varies widely based on liquid viscosity and desired droplet size. For more detailed guidance on how flow rates affect performance, reference industry standards.

Step 4: Inspect Orifices, Seals, and Needles for Wear

Even with perfect maintenance, parts eventually wear out. Pull out the liquid orifice and examine it under good light. Look for enlarged openings, rough edges, scoring, or corrosion.

Check the needle tip for wear, especially if you're seeing dripping issues. Examine all seals and O-rings for cracks, hardening, or deformation. If you're working with misting nozzles or fogging nozzles elsewhere in your facility, you know that seals are often the weak point.

Step 5: Check Fluid Viscosity and Filtration

Is your liquid the same consistency it's supposed to be? Temperature changes, concentration variations, or contamination can all affect viscosity.

Filtration is non-negotiable for air atomizing systems. The general rule: filter to at least half the size of your smallest orifice. If you have a 0.5mm orifice, use a 250-micron or finer filter.

Step 6: Confirm Nozzle Orientation and Mounting

Misalignment causes a surprising number of issues. Double-check that the nozzle is pointed in the right direction and mounted at the correct angle.

Use the proper torque when tightening. Over-tightening can damage threads or deform seals, while under-tightening leads to leaks. For help understanding how proper nozzle selection and positioning affects overall system performance, consult technical resources.

Preventive Maintenance: An Ounce of Prevention

The best troubleshooting is the kind you never have to do. A solid preventive maintenance routine keeps your nozzles running smoothly and catches problems before they impact production.

Establish a cleaning schedule based on your fluid type. Water-based solutions might need weekly attention, while oils or adhesives might require daily cleaning.

Monitor your filtration system. Change filters regularly, not just when they're clogged. A partially blocked filter can cause pressure fluctuations that affect atomization quality.

Replace worn parts proactively. If a needle or seal is showing wear during inspection, replace it during scheduled downtime rather than waiting for it to fail during production.

Avoid over-tightening, which is one of the most common user errors. Damaged threads and compressed seals cause more problems than they solve.

When to Replace Instead of Repair

Sometimes repair just doesn't make sense. Here's when to consider replacing the entire nozzle:

If flow rate has changed by more than 10% from the original specification, even after cleaning. This usually indicates permanent orifice wear.

If atomization quality can't be restored through standard maintenance. When you've cleaned everything, replaced obvious worn parts, and adjusted settings but still can't get proper performance, the nozzle has probably reached the end of its service life.

If you see material degradation or corrosion, the damage might not be repairable.

Do the math: If you're spending significant labor hours repeatedly maintaining a nozzle, the cost of a new nozzle often pays for itself quickly.

Choosing the Right Nozzle for Your Application

Prevention also means using the right tool for the job. If you're constantly fighting with your current nozzles, maybe they're not the best fit.

External mix versus internal mix: Choose external mix for thicker liquids and easier maintenance. Go with an internal mix when you need the finest possible atomization and can guarantee very clean fluids.

Narrow versus wide spray patterns: Match the pattern to your target surface. Wider patterns cover more area but may sacrifice some precision.

Consider consulting with experienced suppliers who understand your industry. At NozzlePro, the technical team can help match nozzle specifications to your exact requirements.

Real-World Applications

Food manufacturing relies on precise coating of products like cereals and snacks. Atomization quality directly impacts appearance and taste distribution.

Metal forming operations use atomized lubrication to reduce friction during stamping or machining. Poor atomization means increased tool wear and potential part defects.

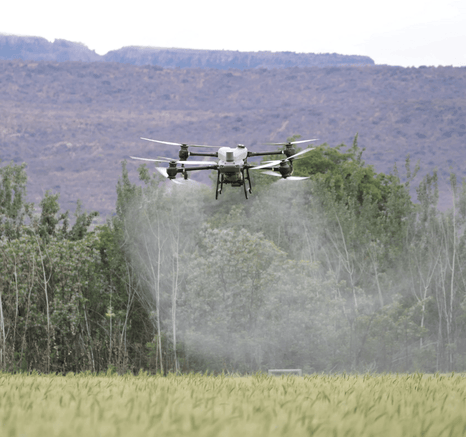

Chemical dosing in water treatment and agriculture demands accuracy. The fine control of air atomizing systems ensures precise application rates.

Humidification and cooling in cleanrooms and manufacturing spaces benefits from the ultra-fine droplets these nozzles produce.

Wrapping Up

Air atomizing nozzles are precision tools that reward proper care with reliable performance. Most problems trace back to contamination, wear, or incorrect operating parameters, all of which are preventable or easily correctable when you know what to look for.

By following systematic troubleshooting steps, maintaining regular cleaning schedules, and knowing when to replace versus repair, you'll minimize downtime and maintain the spray quality your process demands.

Contact NozzlePro's team for expert troubleshooting assistance or guidance on choosing the perfect air atomizing nozzles for your specific needs.

Frequently Asked Questions

Q: How often should I clean my air atomizing nozzles?

A: It depends on your fluid and operating conditions. For water-based solutions, weekly cleaning is usually sufficient. For oils, adhesives, or applications where the fluid dries quickly, you might need daily cleaning. If you notice any change in spray pattern, clean immediately.

Q: What air pressure should I use for air atomizing nozzles?

A: Most operate between 20-90 PSI, but optimal pressure depends on your specific nozzle design, liquid viscosity, and desired droplet size. Always start with the manufacturer's recommended pressure range, then fine-tune based on your results.

Q: Can I use an air atomizing nozzle with thick or viscous liquids?

A: Yes, but you'll need the right nozzle design. External mix nozzles handle thicker liquids better than internal mix designs. You may also need higher air pressure or a larger liquid orifice.

Q: Why does my nozzle keep clogging even after I clean it?

A: Repeated clogging usually points to inadequate filtration of your liquid supply. Check your filter size, it should be at least half the diameter of your smallest orifice. Also verify that your filter is being changed regularly.

Q: What's the difference between a misting nozzle and an air atomizing nozzle?

A: Both create fine droplets, but misting nozzles typically use only high liquid pressure through very small orifices. Air atomizing nozzles use compressed air to break liquid into droplets, giving you more control over droplet size and working better with a wider range of liquids.