So, you want to know about hydraulic nozzles? Well, you're in the right place. These little parts are super important for lots of machines, helping them work right. This article will break down how they work, how we make them better, and some new ideas that are changing the game. We'll look at everything from how liquid moves inside them to how we can use computers to design them. It's all about making things run smoother and more efficiently. Let's dive in and see what makes a good hydraulic nozzle tick.

Key Takeaways

- Understanding how liquid flows inside a hydraulic nozzle is key to making it work well.

- We can make nozzles better by changing their shape and testing them in different situations.

- Computer programs help us design and test nozzles before we even build them.

- The pressure of the liquid really changes how a nozzle performs.

- New ideas are making hydraulic nozzles smarter and more adaptable for different uses.

Understanding Hydraulic Nozzle Flow Dynamics

Analyzing Pressure Distribution and Velocity Fields

When you're trying to get the most out of your hydraulic nozzles, it's important to understand what's happening inside. We're talking about pressure and velocity. Pressure distribution affects how evenly the fluid sprays, and velocity fields dictate the spray's reach and impact.

- Mapping pressure distribution helps identify areas of high stress or potential cavitation.

- Analyzing velocity fields shows how the fluid accelerates and disperses.

- Understanding these factors allows for fine-tuning the nozzle design for optimal performance.

Evaluating Flow Characteristics and Spray Formation

How does a solid stream of liquid turn into a fine mist? That's all about flow characteristics and spray formation. Surface tension, fluid viscosity, and nozzle geometry all play a role. If you can control these, you can control the spray.

- Spray angle: The width of the spray pattern.

- Droplet size: How fine or coarse the spray is.

- Spray distribution: How evenly the fluid is spread across the spray pattern.

Identifying Undesirable Flow Phenomena in Nozzle Design

Not everything goes according to plan inside a nozzle. Sometimes, you get undesirable flow phenomena that mess things up. Things like turbulence, cavitation, and flow separation can reduce efficiency and damage the nozzle.

Understanding these issues is the first step in preventing them. By identifying where and why these problems occur, engineers can modify the nozzle design to minimize their impact. This leads to better performance and a longer lifespan for the nozzle.

Here's a quick rundown of common problems:

- Cavitation: Formation of vapor bubbles that collapse and damage the nozzle.

- Flow separation: Fluid detaches from the nozzle walls, creating turbulence.

- Turbulence: Irregular flow patterns that reduce spray quality.

Optimizing Hydraulic Nozzle Performance

Parametric Studies for Nozzle Geometry Optimization

When it comes to getting the most out of your hydraulic nozzles, it's not just about picking one off the shelf. A big part of the process involves tweaking the nozzle geometry spray nozzles to fit the task. We're talking about running tests to see how different shapes and sizes affect spray patterns, flow rates, and overall efficiency. It's like tuning an engine – small changes can make a huge difference.

- Expansion Ratio

- Contour Shape

- Exit Area

Assessing Nozzle Behavior Across Operating Conditions

Nozzle performance isn't static; it changes based on how you're using it. You need to understand how your nozzle behaves under different pressures, temperatures, and flow rates. This means testing it in a range of conditions to see where it excels and where it falls short.

Understanding how a nozzle performs in various conditions is important for predicting its behavior in real-world applications. This knowledge helps in selecting the right nozzle for the job and optimizing its performance for maximum efficiency and effectiveness.

Enhancing Nozzle Designs for Specific Operating Envelopes

Once you've got a handle on how your nozzle performs, you can start thinking about improvements. This might involve modifying the nozzle's internal structure, changing the materials it's made from, or even adding new features to fine-tune the spray. The goal is to create a nozzle that's perfectly suited for a specific job, whether it's applying coatings, cleaning surfaces, or something else entirely. It's about making sure the nozzle is working smarter, not harder. Here's a few things to consider:

- Material Selection

- Internal Structure

- Spray Pattern Uniformity

Advanced Simulation for Hydraulic Nozzle Design

Okay, so you want to get serious about nozzle design? Forget trial and error. Advanced simulation is where it's at. It lets you virtually test and tweak designs before ever cutting metal. It's like having a wind tunnel on your computer, but for hydraulic nozzles.

Considering Nozzle Geometry and Mesh for Accuracy

Your simulation is only as good as your geometry and mesh. A poorly defined geometry or a coarse mesh can lead to inaccurate results. You need to make sure your mesh is fine enough to capture the important flow features, like boundary layers and shock wave formation. This often means using a finer mesh near the nozzle walls and in regions of high flow gradients.

|

Parameter |

Impact on Accuracy |

|

Mesh Density |

Higher density generally improves accuracy |

|

Element Type |

Structured meshes are often preferred near walls |

|

Mesh Quality |

Avoid highly skewed or distorted elements |

Interpreting Simulation Results for Design Improvement

So, you've run your simulation. Now what? The real skill is in interpreting the results. Look at the pressure distribution, velocity fields, and turbulence intensity. Identify areas of high pressure drop or flow separation. Use this information to guide your design changes. For example, if you see a large recirculation zone, you might need to modify the nozzle profiles to reduce it.

Impact of Pressure Ratios on Hydraulic Nozzles

Pressure ratios are super important when you're talking about how hydraulic nozzles work. Basically, the ratio between the pressure inside the nozzle and the pressure outside affects everything from flow rate to spray pattern. Get it wrong, and you're not getting the performance you need. Let's get into it.

Critical Pressure Ratios and Flow Regimes

There's a point, called the critical pressure ratio, where the flow inside the nozzle reaches its maximum speed – the speed of sound. Go beyond that, and you won't see any more increase in flow rate, no matter how much you crank up the pressure. This is choked flow, and it's a key concept for understanding nozzle behavior. Different flow regimes exist depending on the pressure ratio:

- Subsonic flow: Pressure ratio is below critical, flow speed is less than the speed of sound.

- Sonic flow: Pressure ratio equals critical, flow speed reaches the speed of sound at the nozzle throat.

- Supersonic flow: Pressure ratio is above critical, flow speed exceeds the speed of sound after the throat.

Simulating Overexpanded and Underexpanded Regimes

When the pressure at the nozzle exit doesn't match the surrounding pressure, you get either overexpansion or underexpansion. In overexpanded nozzles, the exit pressure is lower than the ambient pressure, leading to shock waves forming outside the nozzle. Underexpanded nozzles have the opposite problem; the exit pressure is higher, causing expansion waves. Simulating these regimes is vital for predicting performance. Here's a quick comparison:

|

Regime |

Exit Pressure |

Ambient Pressure |

Flow Behavior |

|

Overexpanded |

Lower |

Higher |

External shock waves |

|

Underexpanded |

Higher |

Lower |

External expansion waves |

Getting these simulations right means you can tweak your nozzle design to minimize losses and maximize efficiency. It's all about matching the nozzle to the specific operating conditions.

Optimizing Nozzle Designs for Versatility

To get the most out of your nozzles, you want them to work well across a range of conditions. This means designing them to be less sensitive to changes in pressure ratios. Here are some things to consider:

- Nozzle geometry: Adjusting the shape of the nozzle can help manage expansion and compression waves.

- Operating range: Understand the typical pressure ratios your nozzle will encounter.

- Material selection: Choose materials that can withstand the stresses caused by varying pressures.

Ultimately, the goal is to create a nozzle that delivers consistent performance, no matter what the pressure throws at it. This is especially important for applications where conditions can change rapidly.

Shock Wave Phenomena in Hydraulic Nozzles

Shock waves can really mess with how well a hydraulic nozzle works, especially when dealing with high-speed flows. Understanding how they form and what effects they have is important for designing better nozzles. It's not just about spraying; it's about controlling the spray in the best way possible.

Formation and Characteristics of Shock Waves

Shock waves pop up when flow hits supersonic speeds, usually in convergent-divergent nozzles. These waves are basically abrupt changes in pressure, temperature, and density. The type of shock wave (normal or oblique) depends on the flow conditions and nozzle geometry.

- Normal shock waves are perpendicular to the flow.

- Oblique shock waves are at an angle.

- The stronger the shock, the bigger the change in flow properties.

Changes in Flow Properties Across Shock Waves

When flow crosses a shock wave, several things happen at once. The flow slows down, pressure goes up, and there's a loss of total pressure (or stagnation pressure). This loss means the nozzle isn't as efficient as it could be. Understanding these changes helps in predicting nozzle performance.

|

Property |

Change Across Shock Wave |

Reason |

|

Velocity |

Decreases |

Conversion of kinetic energy to internal energy |

|

Pressure |

Increases |

Compression of the fluid |

|

Density |

Increases |

Compression of the fluid |

|

Total Pressure |

Decreases |

Irreversible process due to entropy increase |

|

Total Temperature |

Remains Constant |

Adiabatic process |

Effects of Shock Waves on Nozzle Efficiency

Shock waves can really hurt nozzle efficiency. They cause losses and can even lead to flow separation, which makes the spray pattern unpredictable. Minimizing or controlling shock waves is key to getting the best performance out of hydraulic nozzles.

Dealing with shock waves often involves tweaking the nozzle design to manage pressure gradients and avoid conditions that cause strong shocks. This might mean changing the nozzle's shape or adjusting operating conditions.

Here are some ways shock waves affect nozzle efficiency:

- Reduced thrust or momentum transfer.

- Increased turbulence and mixing losses.

- Potential for structural damage due to pressure fluctuations.

Innovations in Hydraulic Nozzle Technology

Hydraulic nozzle technology is constantly evolving, driven by the need for greater efficiency, precision, and adaptability in various applications. Let's explore some of the exciting innovations shaping the future of spray technology.

Automatic Gear Shifting in Nozzle Systems

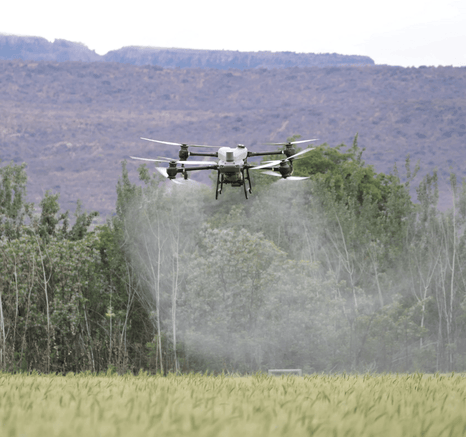

Imagine a nozzle system that automatically adjusts its flow rate and droplet size based on changing operating conditions. That's the idea behind automatic gear shifting in nozzle systems. This technology uses multiple nozzles or variable orifices to optimize performance across a wide range of speeds and pressures.

- Multi-Nozzle Systems: These systems use several nozzles with different flow rates, which are activated or deactivated depending on the required output. This allows for precise control over the spray pattern and droplet size.

- Variable Orifice Nozzles: These nozzles use a mechanically or electronically controlled orifice that can be adjusted to change the flow rate. This provides a continuous range of adjustment, rather than the discrete steps of a multi-nozzle system.

- Electronic Control Systems: Advanced control systems monitor operating conditions such as speed, pressure, and flow rate, and automatically adjust the nozzle settings to maintain optimal performance. These systems often use pulse width modulation to fine-tune the spray characteristics.

Automatic gear shifting in nozzle systems offers several advantages, including improved application accuracy, reduced waste, and increased efficiency. By automatically adjusting to changing conditions, these systems can help to optimize performance and minimize the need for manual adjustments.

Multi-Nozzle Systems for Variable Flow Rates

Multi-nozzle systems are a versatile solution for applications requiring variable flow rates. Instead of relying on a single nozzle to cover the entire operating range, these systems use multiple nozzles with different flow capacities. This allows for precise control over the flow rate and spray pattern, ensuring optimal performance under varying conditions. The spray characteristics can be optimized for different applications.

- Individual Nozzle Control: Each nozzle in the system can be controlled independently, allowing for a wide range of flow rates and spray patterns.

- Modular Design: Multi-nozzle systems are often designed with a modular approach, making it easy to add or remove nozzles as needed.

- Automated Switching: Advanced control systems can automatically switch between nozzles based on operating conditions, ensuring optimal performance at all times.

Maintaining Droplet Size Across Speed Variations

One of the biggest challenges in spray technology is maintaining a consistent droplet size across varying speeds. As speed increases, the pressure in the nozzle also increases, which can lead to smaller droplets and increased drift. Several innovative technologies are being developed to address this issue. It's important to consider the droplet size for the application.

- Pressure Regulation: Pressure regulators can be used to maintain a constant pressure at the nozzle, regardless of the speed. This helps to ensure a consistent droplet size.

- Flow Control Valves: Flow control valves can be used to adjust the flow rate to the nozzle, compensating for changes in speed. This helps to maintain a consistent droplet size and spray pattern.

- Aerodynamic Nozzle Designs: Some nozzle designs use aerodynamic principles to control the droplet size and trajectory. These nozzles can help to reduce drift and improve application accuracy.

|

Technology |

Benefit |

|

Pressure Regulation |

Maintains consistent pressure, ensuring uniform droplet size. |

|

Flow Control Valves |

Adjusts flow rate to compensate for speed changes, maintaining droplet size. |

|

Aerodynamic Design |

Controls droplet size and trajectory, reducing drift. |

Fuel Injector Nozzle Optimization

Fuel injector nozzles are a pretty big deal when it comes to engine performance. We're talking about the heart of how fuel gets into the engine, and any little improvement here can mean better efficiency, lower emissions, and a smoother ride. It's not just about spraying fuel; it's about doing it just right.

Analyzing Pressure Drops Across Injector Nozzles

Understanding how pressure changes as fuel moves through the injector is key. A big pressure drop can mean the nozzle isn't doing its job efficiently, leading to poor fuel atomization. We need to look at the design of the nozzle itself – things like its shape and size – to minimize these losses. It's all about getting the fuel to spray in a consistent, fine mist. This ensures proper combustion and reduces wasted fuel.

Evaluating Velocity Fields and Cavitation Potential

Velocity fields tell us how fast the fuel is moving at different points inside the nozzle. High velocities can cause cavitation, where vapor bubbles form and collapse, potentially damaging the nozzle and messing with the spray pattern. We use simulations to spot these problem areas and tweak the design to avoid them. It's a balancing act – we need enough velocity for good atomization, but not so much that we cause cavitation.

Balancing Performance and Practical Considerations

It's easy to get caught up in chasing the absolute best performance numbers, but we also have to think about real-world stuff. Can the nozzle be manufactured easily? Is it durable enough to last? How much will it cost? Sometimes, a slightly less "perfect" design is better overall because it's more practical. It's about finding that sweet spot where performance meets reality.

Optimizing fuel injector nozzles is a complex process that requires a mix of simulation, testing, and practical know-how. It's not just about making the nozzle spray fuel; it's about making it spray fuel in the most efficient, reliable, and cost-effective way possible. This involves understanding the flow dynamics, minimizing pressure drops, avoiding cavitation, and balancing performance with real-world constraints.

Here are some things to consider:

- Nozzle Material: The material used affects durability and resistance to corrosion.

- Spray Angle: The angle at which the fuel is sprayed impacts combustion efficiency.

- Manufacturing Tolerances: Tighter tolerances can improve performance but increase costs.

Wrapping Things Up

So, we've gone over a lot about hydraulic nozzles. It's pretty clear that picking the right nozzle and making sure it works well is a big deal for how a system performs. Things like the shape of the nozzle, how much pressure is involved, and what kind of liquid you're using all play a part. Getting these details right can make a real difference in how well things work and how long they last. It's not just about getting the job done; it's about doing it the best way possible. Thinking about these things helps make sure everything runs smoothly and efficiently.