Spray nozzle types might not sound like the most exciting topic, but if you work in farming, cleaning, or even manufacturing, you know how important they are. The right nozzle can make the difference between a job done well and a job that’s just a mess. There are so many spray nozzle types out there these days, and each one has its own strengths and quirks. In 2025, with new tech and smarter designs, picking the right nozzle can feel overwhelming. This guide breaks things down in plain English, so you can figure out what spray nozzle types fit your needs—without getting lost in technical jargon.

Key Takeaways

- Choosing the right spray nozzle type depends on factors like droplet size, spray angle, and flow rate.

- Nozzle identification codes help you match the right nozzle to your job, so it’s good to know how to read them.

- Hydraulic nozzles (like flat fan, hollow cone, and full cone) each have specific uses and benefits.

- Modern spray nozzles now feature advanced materials and smart technology, making them more reliable and easier to monitor.

- For agriculture and environmental work, nozzle selection can help reduce drift, save water, and improve application accuracy.

Understanding Spray Nozzle Types and Selection Criteria

Getting the most out of your industrial spray system starts with selecting the right nozzle. There’s more to it than just grabbing any available part—spray nozzle types are as diverse as the tasks they perform. Choosing wisely can save money, prevent downtime, and dial in consistent results across all kinds of operations, from food production to car washing.

Key Factors Influencing Nozzle Performance

Before locking in a purchase, think through these key points that affect spray nozzle effectiveness:

- Liquid properties: Viscosity and surface tension play a big role in how fluids atomize.

- Spray pressure: Higher pressure tends to create smaller droplets, but can increase mist and loss.

- Flow rate: This is often calculated using tools or reference tables, or by reviewing a spray nozzle design calculation pdf.

- Spray angle: Determines coverage width—wider angles usually mean more coverage but finer droplets.

- Material compatibility: Not all nozzles handle every chemical well; match the material to your media.

A simple table like the one below shows how pressure and flow rate affect spray output:

| Pressure (psi) | Flow Rate (gpm) | Typical Droplet Size (µm) |

|---|---|---|

| 20 | 0.3 | 400 |

| 40 | 0.4 | 250 |

| 80 | 0.6 | 165 |

The choice of nozzle really comes down to understanding your process. Small changes in pressure, flow, or media can completely change how a nozzle behaves.

Interpreting Nozzle Identification Codes

Spray nozzles feature a code or number marking on their body, following standards like ISO 10625. This code helps users quickly identify:

- Nozzle type (e.g., flat fan, full cone)

- Orifice size (affects flow rate)

- Spray angle (degree of coverage)

- Construction material (critical for harsh chemicals)

For instance, a nozzle marked “11002-VP” breaks down to:

- 110° spray angle

- 02 = flow rate (in gpm at standard pressure)

- VP = material or manufacturer code

If you’re unsure how these codes translate to real world application, resources like a spray nozzle droplet size calculation or vendor catalogs are your friend. Fast, accurate identification can cut down on downtime in busy industrial environments.

Matching Nozzle Types to Specific Applications

Every industry has its go-to spray nozzle designs, but sometimes picking the right model still comes down to giving the details a closer look. Here’s a quick comparison of common types and use cases:

- Flat Fan: Good for even coverage, like conveyor washing or coating lines.

- Hollow Cone: Aimed at dust suppression or spraying crops where even water distribution isn’t as important as area coverage.

- Full Cone: Often used for cooling or fire protection—excellent for saturating wide spaces.

Selecting the right type can seem overwhelming, but modern tools make it way simpler. Companies like NozzlePro's industry expertise help you sort through thousands of choices with selection guides and friendly support if you get stuck.

Picking the right nozzle isn’t just about flow charts or codes—it’s about understanding how design and application fit together. When you measure things like spray angle, flow, and material carefully, you’ll consistently achieve better efficiency and results in any industrial system.

Hydraulic Spray Nozzle Types and Their Advantages

When it comes to industrial spraying, hydraulic spray nozzles stand out for their simplicity and range. These nozzles work by forcing liquid through a specifically shaped orifice; pressure splits the liquid into droplets, creating distinct spray patterns. Choosing the right nozzle is more than just matching size—each nozzle type offers something unique, whether you're after precision, a certain coverage style, or something that handles tough conditions.

Flat Fan Nozzles for Uniform Coverage

Flat fan nozzles are all about consistency. They release a thin, even sheet of liquid across a set width, providing reliable coverage for large surfaces or rows. Uniformity is what makes these nozzles standard in agricultural and industrial spray booms.

Key Points:

- Tapered flat fans need overlap between spray patterns for even coverage

- Even flat fans don’t need overlap and are good for targeted bands

- Common uses: herbicide and pesticide spraying, surface coating, cooling conveyors

| Feature | Tapered Flat Fan | Even Flat Fan |

|---|---|---|

| Overlap Needed | Yes | No |

| Typical Application | Boom spraying | Row banding |

| Drop Size | Small–medium | Medium |

If you need to cover a big area and keep application rates predictable, flat fan nozzles make life a bit easier—with fewer surprises as you move from section to section.

Hollow Cone Nozzles for Targeted Applications

Hollow cone nozzles have a spray pattern shaped like a ring—a hollow core with most droplets at the edges. This design makes them perfect when you need droplets to reach deep into surfaces or foliage without soaking everything around it.

- Creates fine to medium droplets, ideal for fungicides and insecticides

- Penetrates dense crops or foliage thanks to the ring-shaped pattern

- Fits well in orchard, vineyard, or specialty crop applications

Benefits:

- Low risk of overspray outside the crop target

- Good for applications that rely on hitting undersides or inner leaves

- Used in airblast sprayers and spot-treatments

Full Cone Nozzles for Broad Area Spraying

Full cone nozzles deliver a filled spray pattern—all droplets distributed evenly throughout the cone. This type suits situations where soaking or thorough wetting is needed, like washing, cooling, or certain types of chemical application.

| Attribute | Hollow Cone | Full Cone |

|---|---|---|

| Pattern Shape | Ring/hollow cone | Solid/full cone |

| Droplet Distribution | Edges | Even |

| Typical Use | Foliage, crops | Cleaning, cooling |

- Effective for dust suppression, cooling rooms or equipment, and rinsing tanks

- Better suited for processes where thorough, full-surface contact is important

- Can be found in both agriculture and general industry setups

When detail and deep coverage matter less than broad, even wetting, a full cone nozzle can get the job done with less adjustment and fewer re-sprays.

In summary, hydraulic spray nozzles each have their own strengths. Flat fans do uniform work, hollow cones reach specific targets, and full cones saturate everything. Picking the right one isn’t just technical; it’s about knowing your job and what each pattern can do.

Air Atomizing and Specialized Spray Nozzle Types

Spray applications in 2025 are more complex than ever. Accurate delivery, droplet control, and specialized patterns aren’t optional—they’re standard in industries from food production to aerospace coating. Among the most effective technologies is the air atomizing nozzle, which now comes with a range of options suited for fine misting, high precision, or difficult fluids. Let’s take a closer look at these nozzle types and what makes them uniquely equipped for today’s industrial demands.

Air Atomizing Nozzles for Fine Mist Production

Air atomising nozzles blend liquid and air to create a fine mist, producing droplets much smaller than traditional hydraulic atomizing nozzles. This means you get:

- Precise control of droplet size for demanding applications like humidification, cooling, or applying sensitive coatings

- Cleaner results because the smaller droplets settle more gently and evenly across surfaces

- The ability to atomize even thick or viscous fluids thanks to the integrated air stream

Typical droplet sizes (Volume Median Diameter):

| Nozzle Type | Pressure (psi) | VMD (microns) |

|---|---|---|

| Air Atomizing | 10 | 20 |

| Flat Fan Nozzles | 40 | 260 |

| Hydraulic Atomizing | 100 | 375 |

Even in hard-to-control environments, air atomising nozzles can keep droplet size consistent, leading to higher quality output and less waste.

Twin Fluid Nozzles for Enhanced Versatility

Twin fluid (or two-fluid) nozzles are a specific subset of air atomizing nozzles that use both compressed air and liquid for spraying. This type is especially good when:

- You need a wide operational range from ultra-fine mist to larger drops

- Viscous or temperature-sensitive materials must be sprayed

- Applications call for flexibility without swapping out hardware

Industries using twin fluid atomizing nozzles benefit from adjustable droplet size and are able to manage more challenging spray tasks without downtime.

Nozzles for High Precision Chemical Application

In modern industrial settings, exact placement of chemicals or lubricants is critical. Specialty nozzles offer:

- Narrow, pinpoint patterns to target small areas

- Reduced drift and overspray, limiting waste and environmental exposure

- Consistent metering for dosing accuracy, especially in lab or cleanroom processes

Many process engineers are switching to newer nozzles that include self-cleaning or anti-clog features, which cuts maintenance downtime and ensures every batch gets the right amount of coverage. For broader applications, some industries are still using brass flat spray nozzles to achieve reliable performance across cleaning, cooling, and coating tasks.

Proper nozzle selection in any spray system can save resources, improve product consistency, and boost operator safety. When choosing between flat fan nozzles, air atomizing options, or even more specialized variants, consider both the liquid properties and the environmental requirements. Next-gen air atomizing nozzle technology ensures you can handle even the most exacting spray jobs with confidence.

Critical Spray Nozzle Characteristics and Their Impact

When you're picking out a spray nozzle for an industrial process, it's easy to get overwhelmed by technical options. But the main characteristics—droplet size and distribution, spray angle and pattern, and flow rate with pressure requirements—really determine how effective and efficient your operation will be. Understanding each helps you tailor performance to your needs, rather than hoping a generic solution fits.

Droplet Size and Distribution Considerations

The size of the droplets your nozzle makes shapes everything—from how a chemical hits a surface to whether it drifts or stays put. Small droplets are great for covering a surface evenly, but bigger ones are better for cutting through wind or reaching a target quickly.

Several things affect droplet size:

- Viscosity: Thicker liquids make larger droplets

- Pressure at the nozzle: More pressure usually shrinks droplets

- Nozzle type and orifice size: Design details define the droplet spectrum

| Nozzle Pressure (psi) | Typical Droplet Size (microns) |

|---|---|

| 20 | 500-700 |

| 40 | 300-500 |

| 80 | 150-300 |

Uniform droplet distribution minimizes waste, improves product efficiency, and can boost operational safety.

Spray Angle and Coverage Patterns

The angle at which the nozzle sprays affects the width and depth of coverage. Wide angles spread liquid across a greater area, but lose effectiveness at distance. Narrow angles focus power, but can miss spots if equipment isn't set up just right.

Key considerations for spray angle:

- Wide angles give broad, shallow coverage—good when you need a blanket effect

- Narrow angles reach further and hit smaller targets—useful for spot treatments

- Consistent overlap is necessary to avoid dry or over-wet patches

Spray pattern matters, too:

- Flat fan: even, narrow bands

- Hollow cone: a ring of drops, center less dense

- Full cone: even, round pattern, higher hit rate

Flow Rate and Operating Pressure Requirements

Flow rate tells you how much liquid comes out per minute or hour, often measured in gallons or liters. Too low a flow and you’re under-applying; too high and you’re wasting chemicals, water, or energy.

Pressure works with flow to define spray energy and reach:

- Higher pressure: smaller drops, but risk of drift

- Lower pressure: larger drops, less drift, but poor atomization

Typical requirements:

- Low-pressure, high-volume for large area coverage

- High-pressure, low-volume for fine mist or tight targets

Adjusting pressure or swapping nozzles is sometimes all it takes to match an application—easy when you know the impact.”

Innovations in Spray Nozzle Types for Modern Industry

Spray nozzles have changed a lot in recent years. New demands in industrial spray nozzles have led to smarter designs and even smarter monitoring. If you work with sprays, whether that's in chemical plants, food production, or even paper manufacturing, knowing the latest upgrades can save time, money, and resources.

Advanced Materials and Construction Methods

The days of only relying on basic metals or plastics are over. Modern industrial nozzles use blends like 304 stainless steel, ceramics, and custom polymers. These materials:

- Resist corrosion from aggressive chemicals and abrasive slurries

- Are easier to clean, making them ideal for spray technology for tissue and food processing

- Offer longer lifespans, even in challenging pulp production environments

Here's a look at how material advances stack up:

| Material Type | Core Benefit | Common Use Case |

|---|---|---|

| Stainless Steel | Corrosion Resistance | Industrial spray nozzle |

| Ceramics | Abrasion Resistance | Solid stream nozzles |

| Engineered Plastics | Light Weight, Clean | Pulp, tissue, food |

Just having the right construction means fewer changeouts, something anyone running a line will appreciate. For example, some high-precision flat spray nozzle designs now pair top-grade steel with even flow rates for better cooling and coating.

Smart Nozzle Technologies in 2025

Digital controls on nozzles seemed far-fetched a decade ago. Now, they're close to standard in many places. A typical nozzle pro setup can include:

- Integrated sensors to check flow, pressure, and spray patterns automatically

- Wireless controls—change spray characteristics from a smartphone or the plant control room

- Self-cleaning features for high-solids applications

These systems help keep lines running. No more guessing if you have a clog or drift. Real-time alerts mean issues get fixed fast. When it comes to spray technology for tissues or chemical production, that's big.

As factories turn smarter, integrating digital monitoring with industrial spray nozzles is making production lines more responsive, reliable, and efficient—streamlining troubleshooting and boosting consistency in every spray pattern.

Analytical Tools for Nozzle Performance Assessment

If you've ever struggled getting the right droplet size or wasted hours dialing in a spray angle, you'll like this part. New analytic and modeling tools now let you:

- Measure droplet size using laser diffraction or advanced image analysis

- Run flow simulations to see exactly how a nozzle will behave on your unique feed

- Adjust parameters quickly based on real data, not just charts

Some industries, especially where spray technology for pulp production is used, rely heavily on these tools to meet strict guidelines for droplet consistency and coverage.

The progress in measuring and fine-tuning industrial nozzles means you get reliable, repeatable results—no more guessing games. All these upgrades make a difference whether you're spraying coatings, cleaning, or applying precise amounts of chemicals.

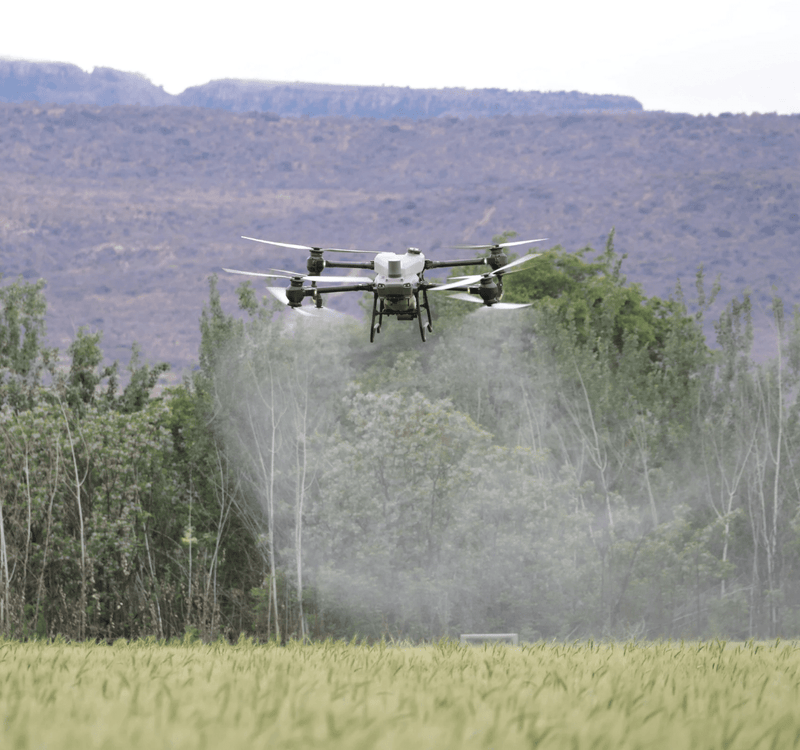

Spray Nozzle Types for Agriculture and Environmental Uses

Modern agriculture and environmental management expect a lot from spray nozzles. Tasks like pesticide delivery, protecting crops, reducing drift, saving water—all of these jobs demand specific designs and features. The choices can seem endless: flat fans, cones, specialty types, or spray nozzle for PVC pipe setups—each brings something different to the field. Let's take a closer look at how nozzles are making an impact in 2025.

Pesticide and Herbicide Application Strategies

Choosing the right spray nozzle is critical to effective pesticide and herbicide use. Here’s what matters:

- Droplet Size: Smaller droplets often mean better coverage but are more likely to drift. Larger droplets reduce drift but may miss fine coverage on leaves.

- Spray Pattern: Flat fan and even flat fan nozzles work well for broadcast and banded applications. Hollow cone nozzles are common for orchards or target spraying where crop canopies are dense.

- Pressure Options: Options like a 1 inch spray nozzle or pressure spray nozzle help tailor delivery for different field conditions and chemical needs.

| Nozzle Type | Best For | Common Droplet Size |

|---|---|---|

| Flat Fan | Broadfield, row crops | Medium |

| Hollow Cone | Tree crops, target spray | Fine/Medium |

| Full Cone | Fungicides, thorough wetting | Coarse/Medium |

Drift Reduction Technologies

Pesticide and fertilizer drift is a real concern for farms and the environment. Here are three ways new nozzle designs are combating drift:

- Low-Drift Nozzles – These use air-induction or special orifices to produce heavier droplets that fall quickly, limiting off-target movement.

- Pressure Regulation – Consistent pressure at the nozzle ensures the right droplet size, avoiding misting and excessive fine spray.

- Shielded Spray Bars and Extensions – Protecting the spray zone, especially with a spray nozzle for PVC pipe systems, reduces wind effects and drift outside of the treatment area.

Nozzle Designs for Water Conservation

Water matters just as much as chemicals on today’s farms. The push is on for every drop to count, especially in dry regions or for sensitive applications like tank cleaning.

- Precision Application: Modern nozzles let operators adjust flow rate and spray angle to use less water without losing coverage.

- Tank Cleaning Nozzles: These are designed to use high-velocity jets (like a pressure spray nozzle) to clean tanks quickly and thoroughly, saving both water and labor.

- Material Selection: Lightweight, corrosion-resistant materials—PVC, stainless steel, engineering plastics—mean even a 1 inch spray nozzle can handle fertilizer, wastewater, or clean water without waste or rapid wear.

Think of spray nozzles as the silent force behind smarter farming and cleaner environments. When you choose the right type for your field, crop, and water source, you get more control, greater efficiency, and less environmental impact—all without sacrificing the results you're after.

Conclusion

So, after looking at all these different spray nozzle types and what they do, it’s pretty clear there’s no one-size-fits-all answer. The right nozzle really depends on what you’re trying to accomplish—whether that’s cleaning, cooling, coating, or something else entirely. Over the years, nozzles have gotten more specialized, and the tools for picking the right one have gotten a lot better, too. It’s not just about grabbing whatever’s on the shelf anymore. You’ve got to think about things like droplet size, spray pattern, and even the material of the nozzle itself. If you’re not sure, don’t be afraid to ask for help or use one of those online selection tools. In the end, taking a little extra time to pick the right nozzle can save you a lot of hassle and money down the road. Hopefully, this guide has made things a bit clearer and will help you make better choices for your spraying needs in 2025 and beyond.