In the industrial world, precision and efficiency are key. One tool that stands out for applications involving air and fluid sprays is the air-assisted nozzle. This article will explore what these nozzles are, their benefits, and how to choose the right one for your needs.

Key Takeaways

- Air-assisted nozzles offer better atomization compared to traditional methods.

- These nozzles improve transfer efficiency, making processes more efficient.

- They require less maintenance, saving time and costs.

- Air-assisted nozzles can be used in various industries, from food processing to agriculture.

- There are some challenges, like handling high-viscosity materials and additional airline requirements.

Understanding Air-Assisted Nozzles in Industrial Applications

Definition and Mechanism

Air-assisted nozzles are essential tools in industrial spraying systems. They mix air and liquid to create fine droplets, which are then sprayed onto surfaces. This process can be done either inside the nozzle (internal mixing) or outside the nozzle (external mixing). Internal mixing achieves smaller droplet sizes, making it ideal for applications like dust suppression.

Types of Air-Assisted Nozzles

There are two main types of air-assisted nozzles: internal-mixing and external-mixing. Internal-mixing nozzles mix air and liquid inside the nozzle, resulting in finer droplets. External-mixing nozzles mix air and liquid outside the nozzle, offering more control over spray patterns.

Common Industrial Uses

Air-assisted nozzles are used in various industries for tasks such as dust suppression, coating, and cooling. They are particularly valuable in environments where precision and efficiency are crucial, like food processing and mining.

Air-assisted nozzles are vital for achieving high efficiency and precision in industrial spraying applications.

Advantages of Air-Assisted Nozzles Over Traditional Methods

Enhanced Atomization

Air-assisted nozzles offer a "soft" spray atomization, which is achieved with low air pressures, typically under 20 psi. This results in a fine finish that is comparable to compressed-air atomization. The gentle atomization process ensures a high-quality application, making it ideal for various coatings.

Improved Transfer Efficiency

One of the standout benefits of air-assisted nozzles is their improved transfer efficiency. Studies show an approximate 30% increase in transfer efficiency over traditional compressed air methods. This means more material reaches the target surface, reducing waste and saving costs.

Reduced Maintenance Requirements

Air-assisted nozzles also contribute to lower maintenance needs. The system's design minimizes material bounce-back, which leads to less booth maintenance and cleanup time. Additionally, the lower fluid pressures, generally ranging from 200-800 psi, result in less wear on the pump and nozzle tips, extending their lifespan.

The combination of enhanced atomization, improved transfer efficiency, and reduced maintenance makes air-assisted nozzles a superior choice for many industrial applications.

Technical Aspects of Air-Assisted Nozzles

Operating Pressures

Air-assisted nozzles operate under specific pressure ranges to achieve optimal atomization. Maintaining the correct pressure is crucial for efficient performance. Typically, these nozzles function between 20 to 100 psi for air pressure and 10 to 50 psi for liquid pressure. Operators must avoid excessive pressures, as this can reduce transfer efficiency and lead to wastage.

Material Compatibility

Selecting the right materials for air-assisted nozzles is essential to ensure durability and compatibility with the fluids being sprayed. Common materials include stainless steel, brass, and various plastics. Each material has its own advantages and limitations, depending on the application and the chemical properties of the fluids.

Design Considerations

The design of air-assisted nozzles involves several factors, including the internal structure and the air-liquid mixing method. Internal-mixing nozzles mix air and liquid inside the nozzle, resulting in finer droplets. External-mixing nozzles mix air and liquid outside the nozzle, offering more control over spray patterns. Understanding these design elements helps in selecting the right nozzle for specific industrial needs.

Applications of Air-Assisted Nozzles in Various Industries

Food Processing

In the food processing industry, air-assisted nozzles are essential for tasks such as coating, cleaning, and sanitizing. They ensure precise application of liquids, which is crucial for maintaining hygiene and product quality. These nozzles help in evenly distributing coatings on food products, thereby enhancing flavor and appearance.

Mining and Dust Suppression

Air-assisted nozzles play a significant role in mining operations, particularly in dust suppression. By atomizing water into fine droplets, these nozzles effectively reduce airborne dust, improving air quality and safety in mining environments. This not only protects workers but also helps in complying with environmental regulations.

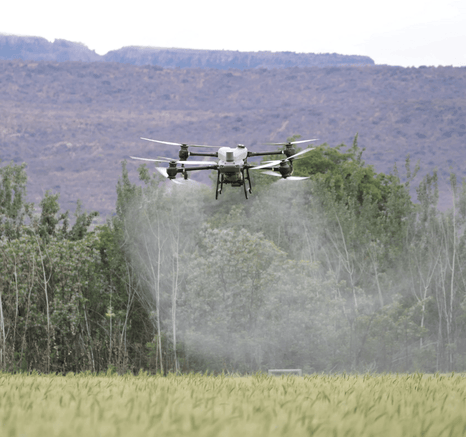

Agricultural Spraying

In agriculture, air-assisted nozzles are used for spraying pesticides, herbicides, and fertilizers. They provide better coverage and penetration, ensuring that crops receive the necessary treatments uniformly. This leads to healthier plants and higher yields. Additionally, these nozzles help in reducing the amount of chemicals used, making farming practices more sustainable.

Air-assisted nozzles are versatile tools that enhance efficiency and precision across various industries, from food processing to agriculture.

Challenges and Limitations of Air-Assisted Nozzles

Handling High-Viscosity Materials

Air-assisted nozzles often struggle with spraying high-viscosity materials. They typically do not come in high-ratio pumps, which limits their ability to handle thicker substances effectively. This can be a significant drawback in industries where high-viscosity materials are common.

Additional Airline Requirements

Using air-assisted nozzles necessitates an additional airline, which can complicate the setup. This extra line can be cumbersome and may require more careful handling and maintenance. Operators need to be mindful of this added complexity when integrating air-assisted nozzles into their systems.

Cost Implications

Air-assisted nozzles tend to be more expensive than their airless counterparts. This is primarily due to the use of atomization air, which adds to the overall cost. While the benefits may outweigh the costs in many applications, the initial investment can be a barrier for some users.

Despite these challenges, air-assisted nozzles offer significant advantages in terms of atomization and efficiency, making them a valuable tool in various industrial applications.

Innovations and Future Trends in Air-Assisted Nozzle Technology

Advancements in Atomization Techniques

Recent developments in atomization techniques have significantly improved the performance of air-assisted nozzles. Enhanced droplet size control and more efficient mixing methods are at the forefront of these innovations. These advancements lead to better spray patterns and more effective applications in various industries.

Integration with Smart Systems

The integration of air-assisted nozzles with smart systems is revolutionizing industrial applications. Smart nozzles can now be controlled and monitored remotely, allowing for real-time adjustments and improved efficiency. This integration also facilitates predictive maintenance, reducing downtime and operational costs.

Sustainability and Environmental Impact

Sustainability is a growing concern in industrial applications, and air-assisted nozzles are no exception. Innovations are focusing on reducing energy consumption and minimizing waste. Eco-friendly materials and designs are being developed to lessen the environmental impact, making these nozzles a more sustainable choice for industries.

Best Practices for Selecting and Using Air-Assisted Nozzles

Criteria for Selection

When choosing an air-assisted nozzle, it's crucial to consider the specific needs of your application. Key factors to evaluate include the type of fluid being sprayed, the desired spray pattern, and the operating environment. For instance, if you're dealing with a viscous fluid, a larger nozzle may be necessary.

Maintenance Tips

Regular maintenance is essential to ensure the longevity and performance of your nozzles. This includes routine cleaning to prevent clogging and periodic inspections to identify wear and tear. Using NozzlePro products can simplify maintenance due to their robust design and high-quality materials.

Safety Considerations

Safety should always be a priority when using air-assisted nozzles. Ensure that all operators are trained in the proper use of the equipment and are aware of the potential hazards. Additionally, always follow the manufacturer's guidelines for safe operation and maintenance.

Proper selection and maintenance of air-assisted nozzles can significantly enhance the efficiency and safety of your industrial applications.

Choosing the right air-assisted nozzle can make a big difference in your spraying tasks. It's important to consider factors like spray pattern, pressure, and material compatibility. For more tips and to explore our wide range of nozzles, explore our website. We're here to help you find the perfect nozzle for your needs.

Conclusion

In conclusion, air-assisted nozzles offer numerous benefits for industrial applications. They provide precise and efficient spraying, which is essential for various industries such as food processing, mining, and agriculture. These nozzles help improve transfer efficiency, reduce maintenance time, and lower operational costs. Despite some limitations, their advantages make them an indispensable tool in modern industrial processes. By understanding and utilizing air-assisted nozzles, industries can achieve better performance and productivity.