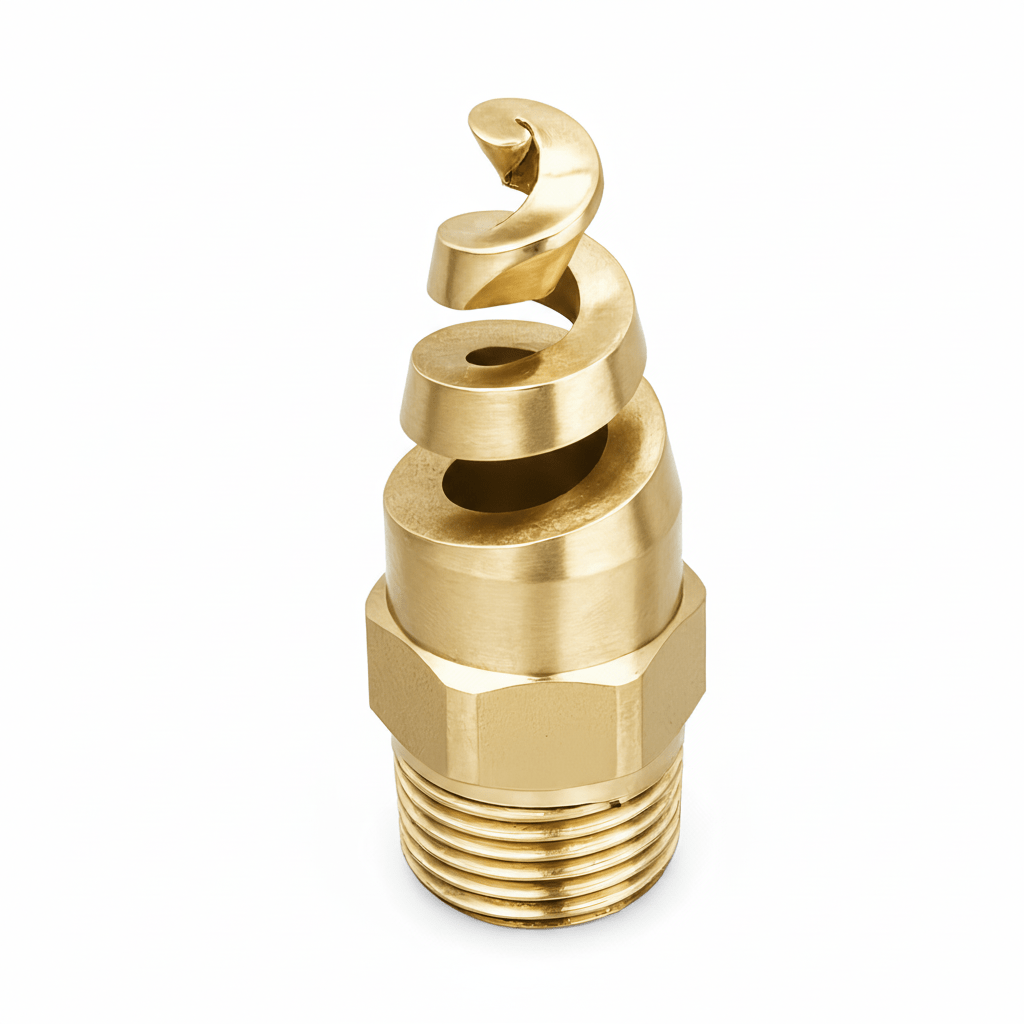

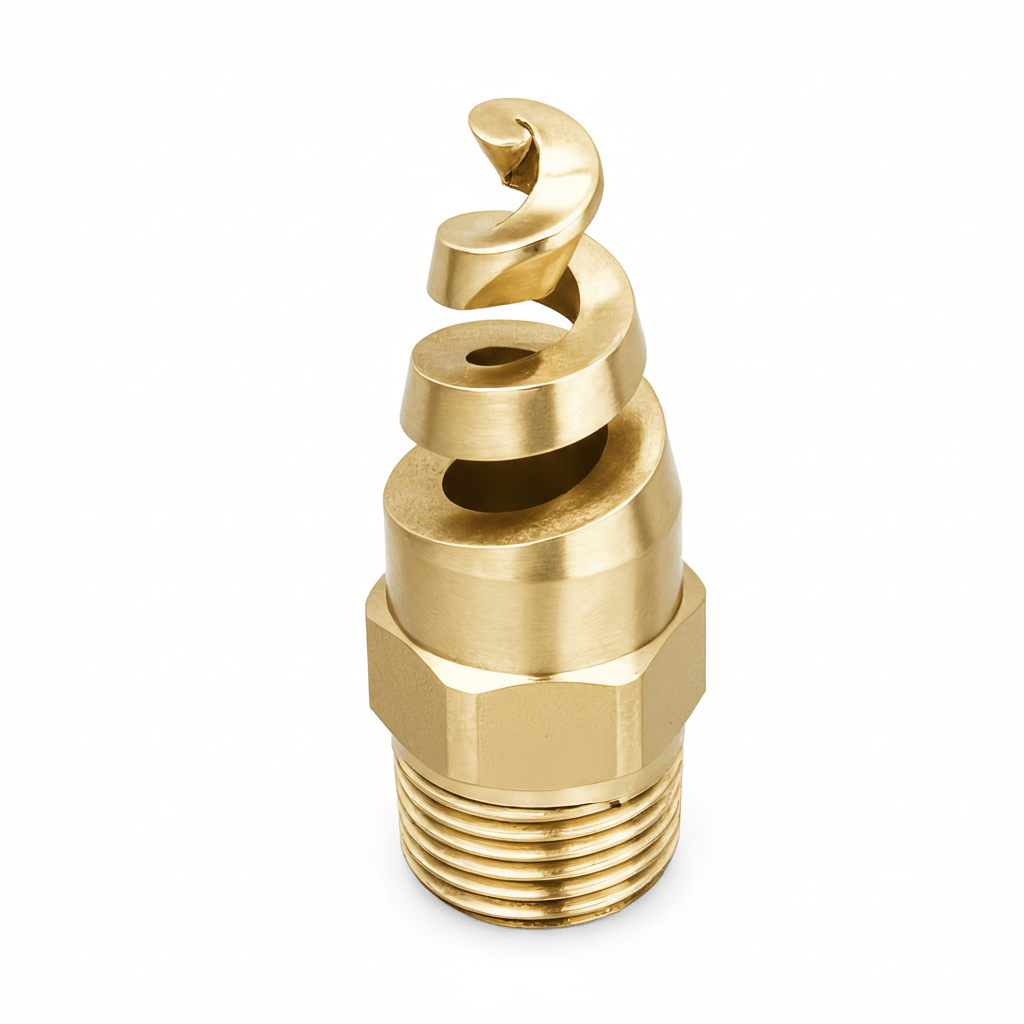

Product Parameters

| Product Family | Hollow Cone Spiral |

|---|---|

| Product Series | NPSJ |

| Capacity Size | 340 |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | MALE (M) |

| Material Composition Filter | Brass |

| Orifice Diameter. Nom. (mm) | 15.9 |

| Inlet Connection Size (in.) | 1 |

| Length (mm) | 92.1 |

| Hex Size (mm) | 34.9 |

| Spray Angle at Rated Pressure (PSI) | 60 |

| Max. Free Passage Dia. (mm) | 6.4 |

Description

Product Overview

Inside the Energy line's cooling & quenching stage, a quality manager relies on the NPSJ-60340-1 to deliver consistent and uniform spray coverage. Constructed from brass, this precision hollow cone, spiral nozzle ensures durability and corrosion resistance under continuous use. The single inlet design allows for straightforward integration into existing systems, while the hollow cone spray pattern optimizes fluid distribution to maintain process temperatures and protect equipment. Operators monitor spray uniformity closely to meet exacting cooling specifications and avoid thermal stress.

Applications

The NPSJ-60340-1 plays a critical role in cleaning & washing procedures where controlled spray coverage removes residues without damaging sensitive surfaces. In cooling & quenching operations, the nozzle's consistent mist reduces thermal shock and improves material properties downstream in the production cycle.

Industries

This nozzle is favored in industries such as building materials, chemical processing, and steel & metals because it withstands harsh environments and delivers reliable performance. Breweries & wineries, cement, mining, dairy, and manufacturing & assembly also depend on its corrosion resistance and spray precision to maintain process integrity and product quality.