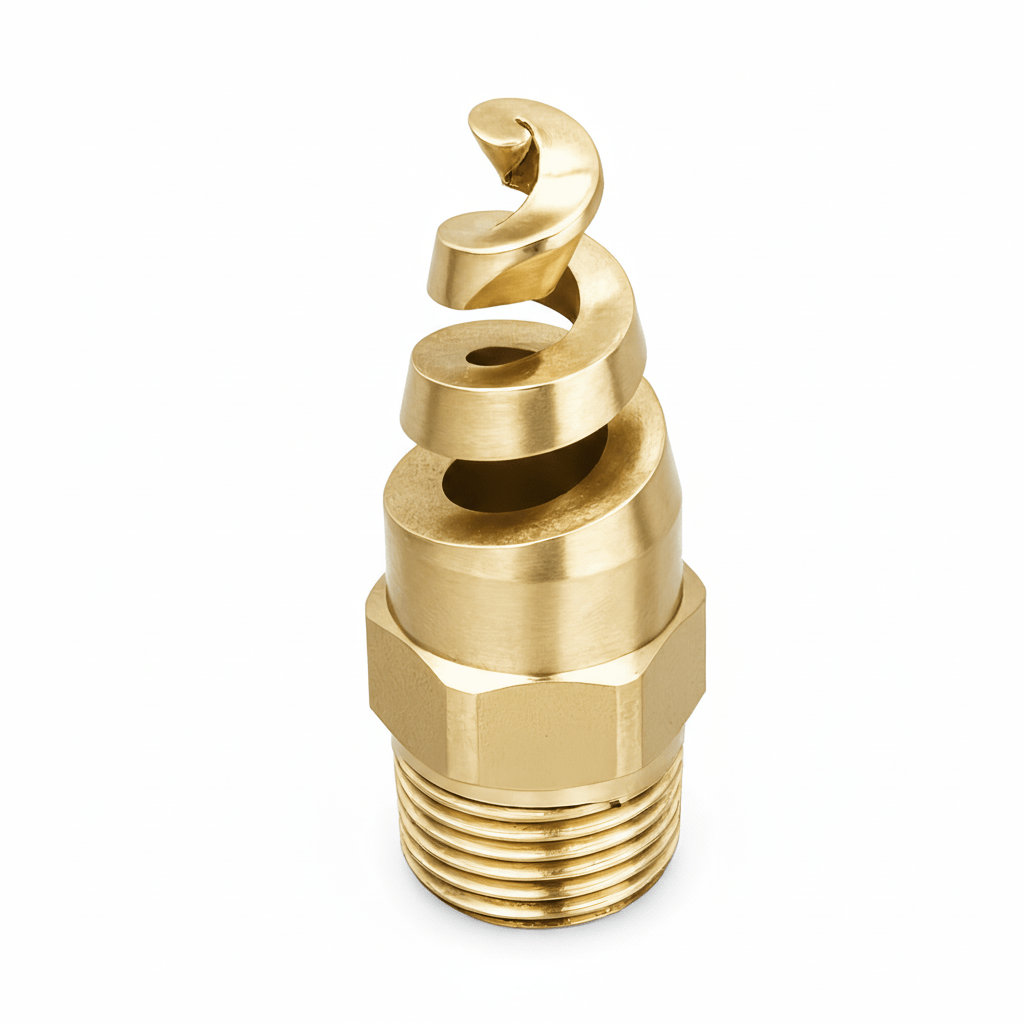

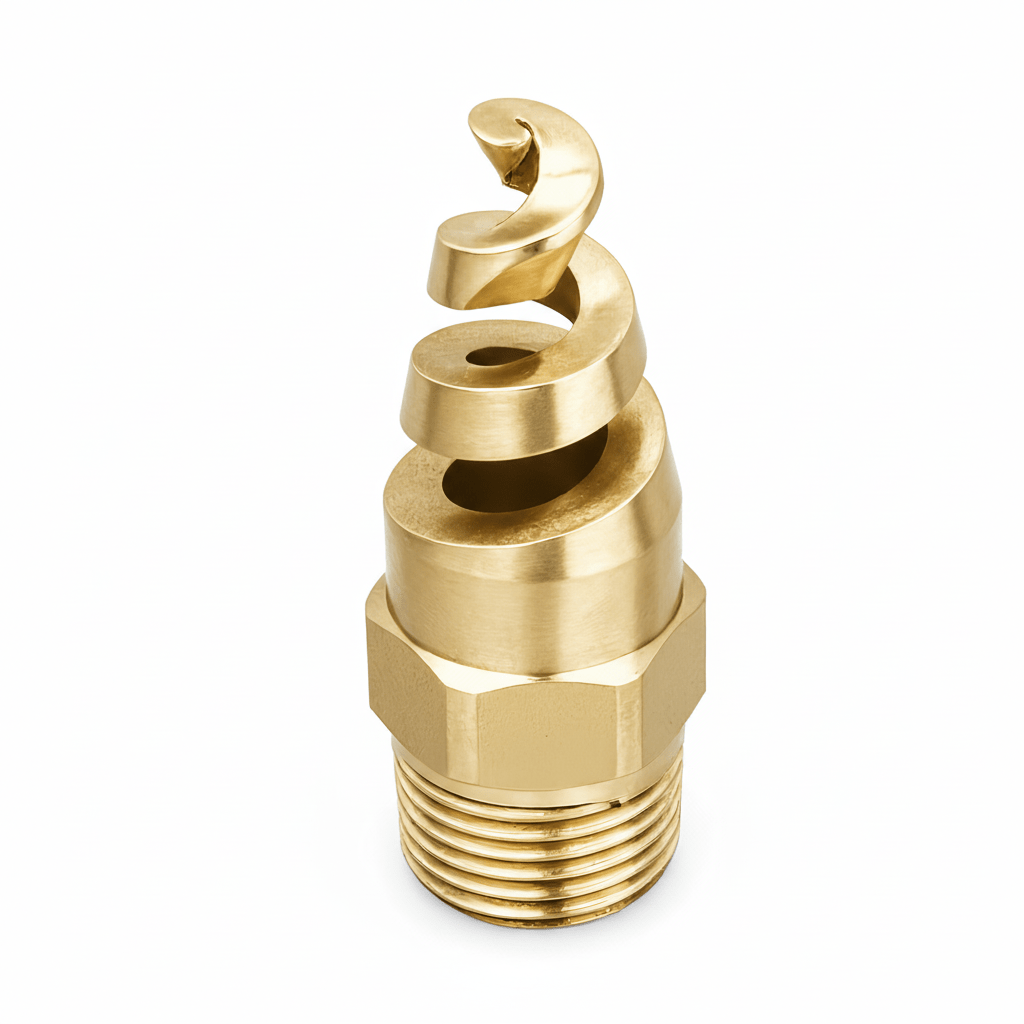

Product Parameters

| Product Family | Hollow Cone Spiral |

|---|---|

| Product Series | NPSJ |

| Capacity Size | 40 |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | MALE (M) |

| Material Composition Filter | Brass |

| Orifice Diameter. Nom. (mm) | 5.6 |

| Inlet Connection Size (in.) | 3/8 |

| Length (mm) | 47.6 |

| Hex Size (mm) | 17.5 |

| Spray Angle at Rated Pressure (PSI) | 170 |

| Max. Free Passage Dia. (mm) | 3.2 |

Description

Product Overview

Inside the breweries & wineries line's fire protection & safety stage, a process engineer relies on the NPSJ-17040-3/8 to deliver a consistent hollow cone spray pattern that enhances coverage while minimizing water use. Constructed from brass, this nozzle withstands corrosive environments typical of cleaning cycles and chemical exposure. When installed through the 3/8 inch inlet, it provides uniform atomization that supports regulatory compliance and reduces downtime in critical safety applications. The engineer monitors flow rates and spray angles to ensure precision and effective response during fire suppression activities.

Applications

In cleaning & washing, the nozzle ensures thorough surface coverage which aids in removing residues and contaminants efficiently. Its use in cooling & quenching processes helps regulate temperature uniformly, preventing thermal stress and material deformation in downstream operations.

Industries

Sectors such as building materials, chemical processing, mining, and steel & metals integrate this nozzle due to its corrosion resistance and uniform spray delivery under demanding conditions. Breweries & wineries and cement plants also benefit from its reliable performance in processes requiring precise fluid distribution and safety management.