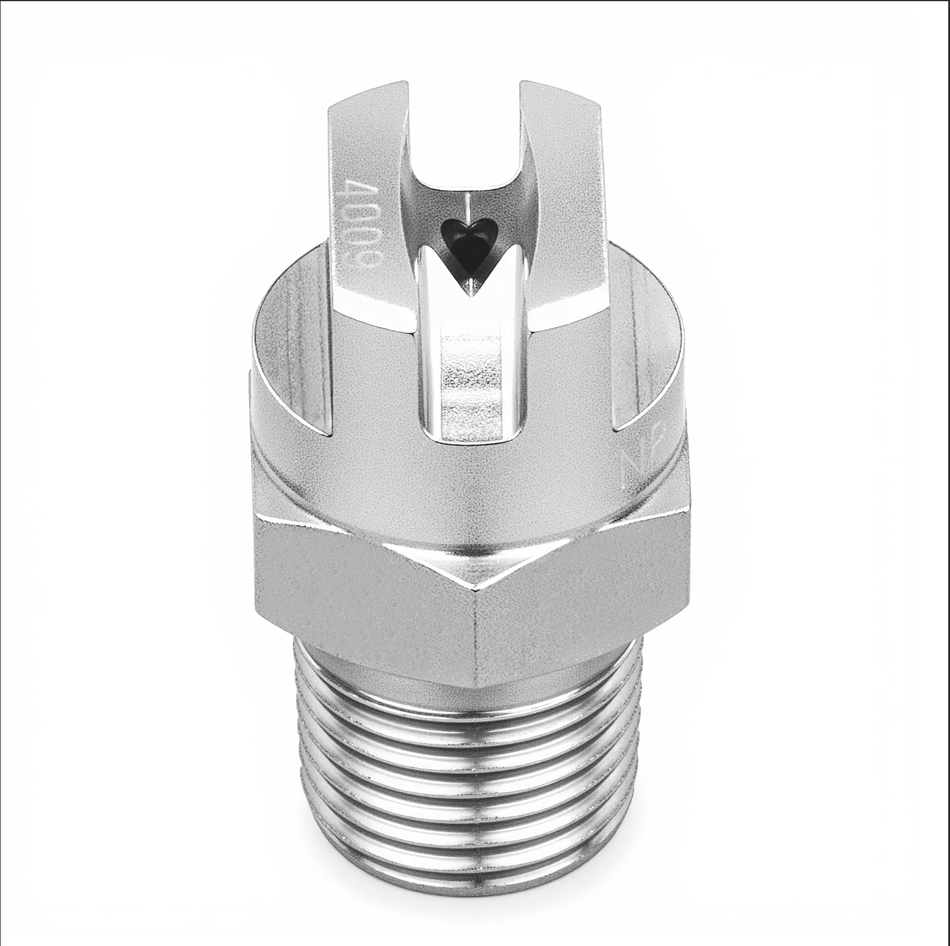

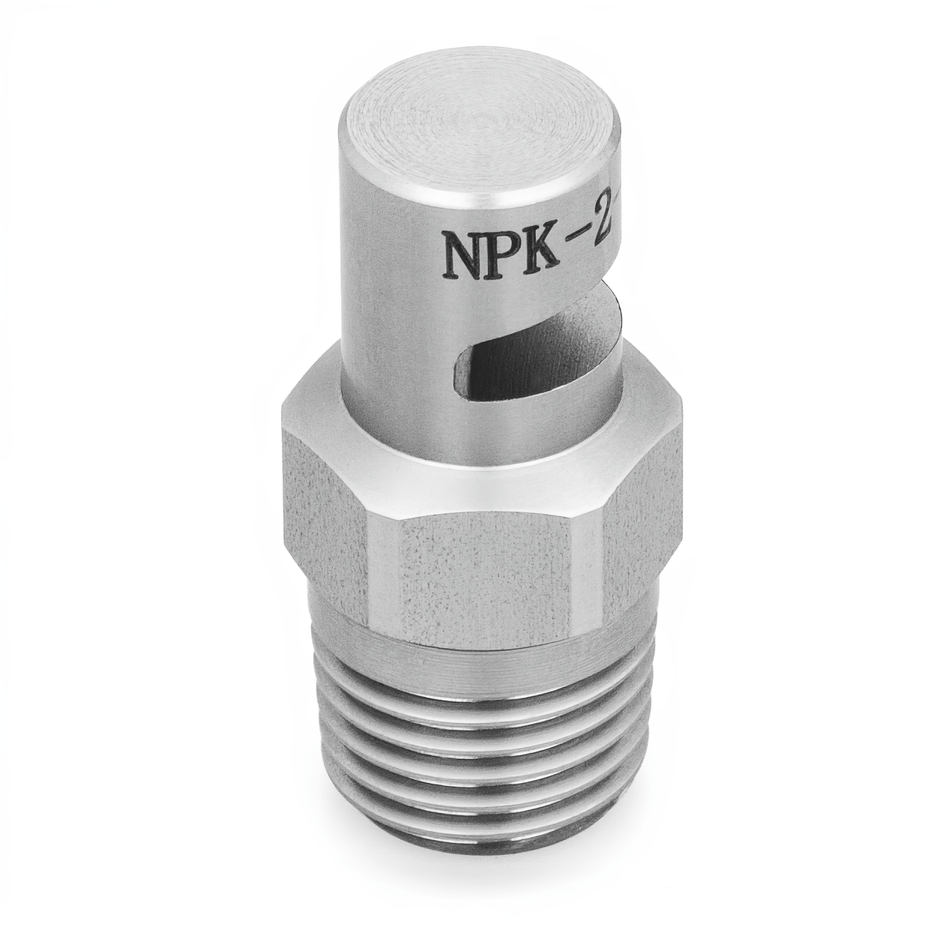

Product Parameters

| Product Family | Flat |

|---|---|

| Product Series | NPHVL |

| Capacity Size | 8 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | 316L stainless steel |

| Inlet Connection Size (in.) | 1/4 |

| Length (mm) | 38 |

| Length (in) | 1.250 |

| Hex Size (mm) | 14.3 |

| Hex Size (in) | 9/16 |

| Equivalent Orifice Diameter (in) | 0.071 |

| Spray Angle at Rated Pressure (PSI) | 80 |

| Equivalent Orifice Diameter (mm) | 1.8 |

Description

Product Overview

Inside the meat & poultry line's cooling & quenching stage, a quality manager relies on the NPHVL-8008-1/4-316 to deliver consistent spray coverage essential for rapid temperature reduction. Constructed from 316L stainless steel, this nozzle withstands corrosive washdown procedures while maintaining precise flat spray patterns. Operators integrate the nozzle with a 1/4-inch inlet piping, ensuring uniform fluid distribution that minimizes product variability and supports food safety standards. The reliability of this nozzle contributes directly to process efficiency and product quality control.

Applications

In cleaning & washing processes, the NPHVL-8008-1/4-316 provides uniform spray distribution that improves residue removal and surface hygiene. Its use in cooling & quenching accelerates temperature stabilization, which enhances throughput and reduces thermal stress on equipment and products downstream.

Industries

This nozzle is favored in automotive, mining, and steel & metals sectors for its corrosion resistance and consistent spray, which are critical under harsh operating conditions. Additionally, industries such as bakery & confectionery, beverage bottling & packaging, and Energy select this component for applications requiring precise fluid handling and durability in demanding environments.