Product Parameters

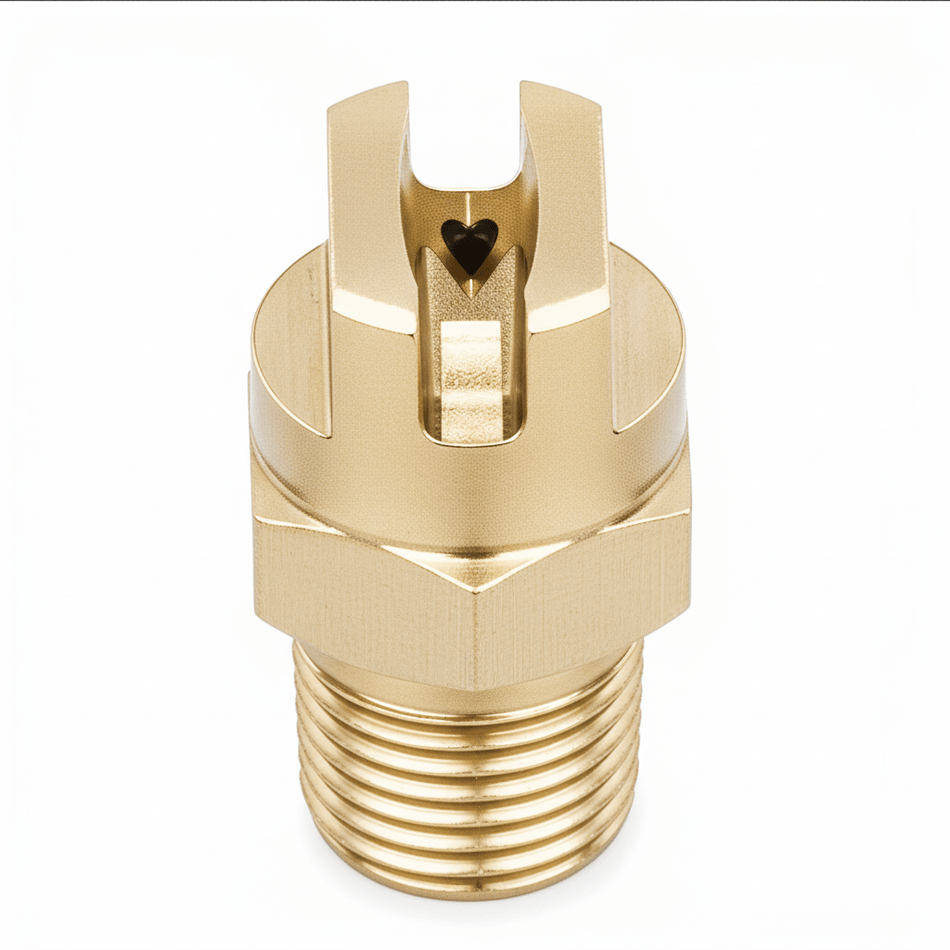

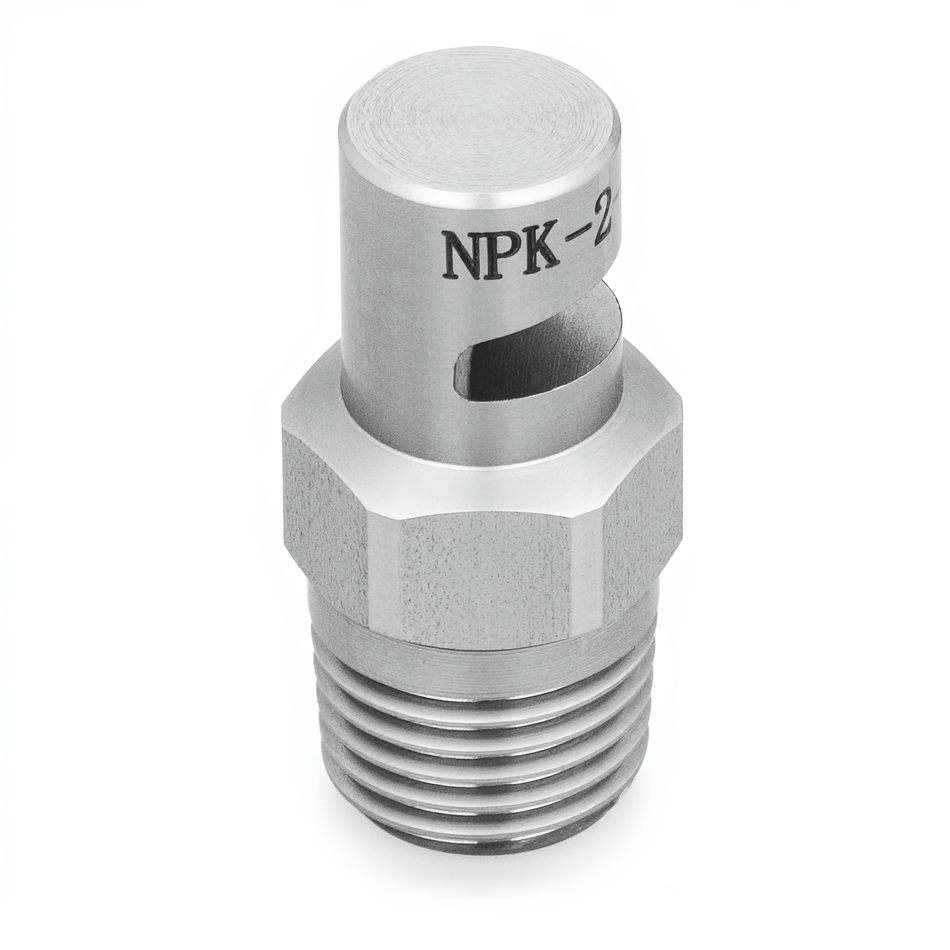

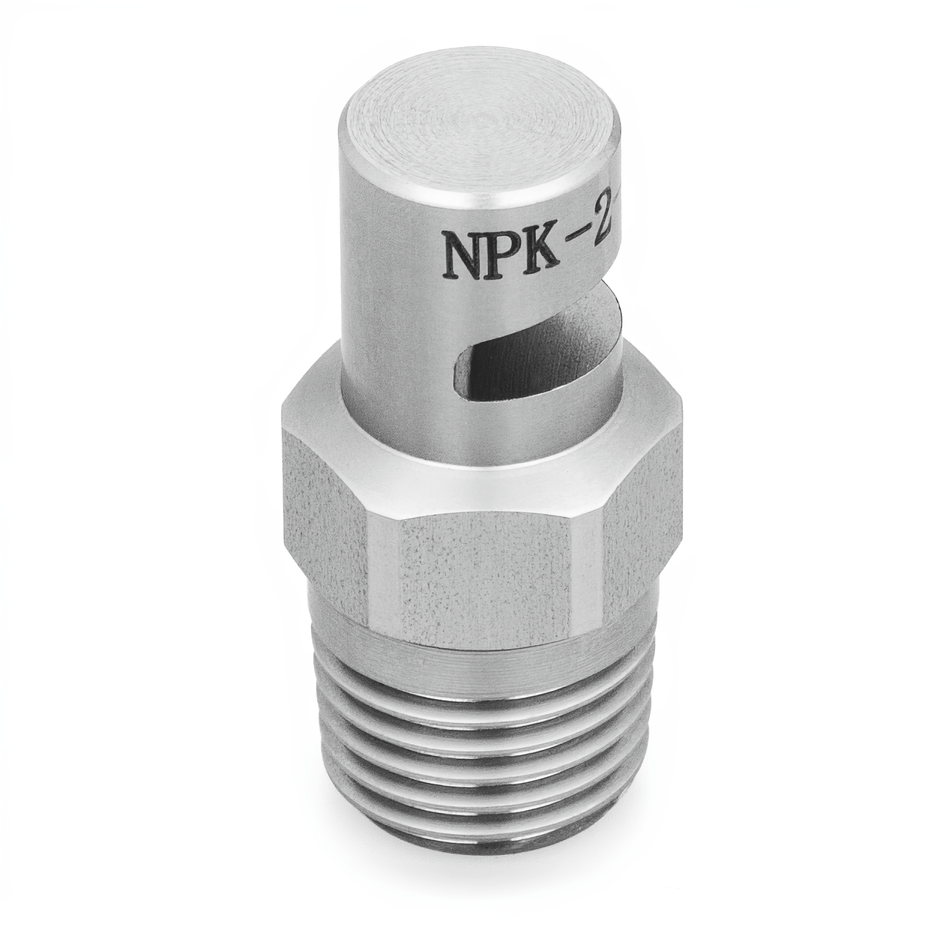

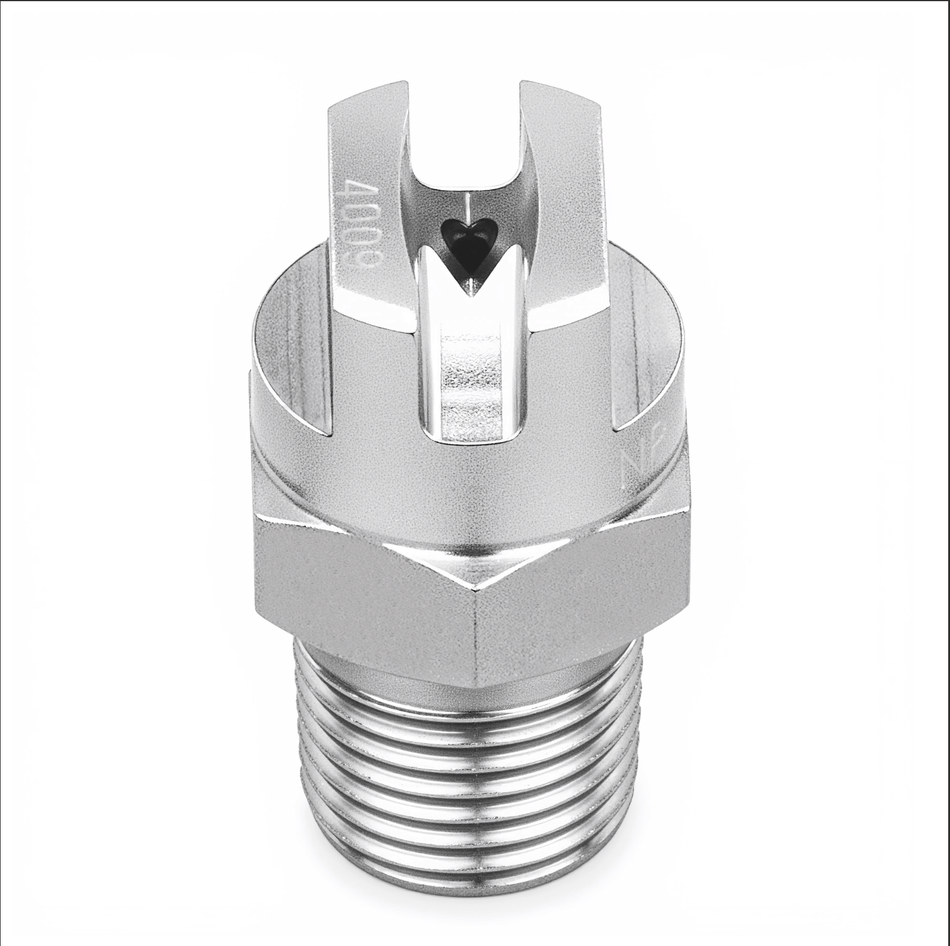

| Product Family | Flat |

|---|---|

| Product Series | NPHVL |

| Capacity Size | 3 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | 303/304 stainless steel |

| Inlet Connection Size (in.) | 1/8 |

| Length (mm) | 36 |

| Length (in) | 1.531 |

| Hex Size (mm) | 12.7 |

| Hex Size (in) | 1/2 |

| Equivalent Orifice Diameter (in) | 0.043 |

| Spray Angle at Rated Pressure (PSI) | 65 |

| Equivalent Orifice Diameter (mm) | 1.1 |

Description

Product Overview

During cooling & quenching on a bakery & confectionery site, quality managers trust the NPHVL-6503-1/8-SS to deliver consistent, uniform spray coverage essential for temperature control and product integrity. The nozzle's 303/304 stainless steel construction withstands the corrosive environment typical of food production, ensuring longevity and reliable operation. Operators install the nozzle with its 1/8 inlet seamlessly into existing spray systems, resulting in precise flat spray patterns that reduce waste and improve process repeatability. This part enables measurable improvements in cooling efficiency and downtime reduction.

Applications

In cleaning & washing processes, the NPHVL-6503-1/8-SS provides steady, even spray distribution that enhances residue removal without damaging delicate surfaces. Its role in cooling & quenching applications supports thermal regulation, which directly impacts product consistency and equipment uptime across multiple manufacturing lines.

Industries

The nozzle is frequently selected by professionals in automotive, steel & metals, and manufacturing & assembly due to its corrosion resistance and reliable spray performance under harsh conditions. Additionally, sectors such as food & beverage, cement, and Energy benefit from its adaptability in coating & surface treatment and dust & pollution control tasks, where precise liquid delivery is critical.