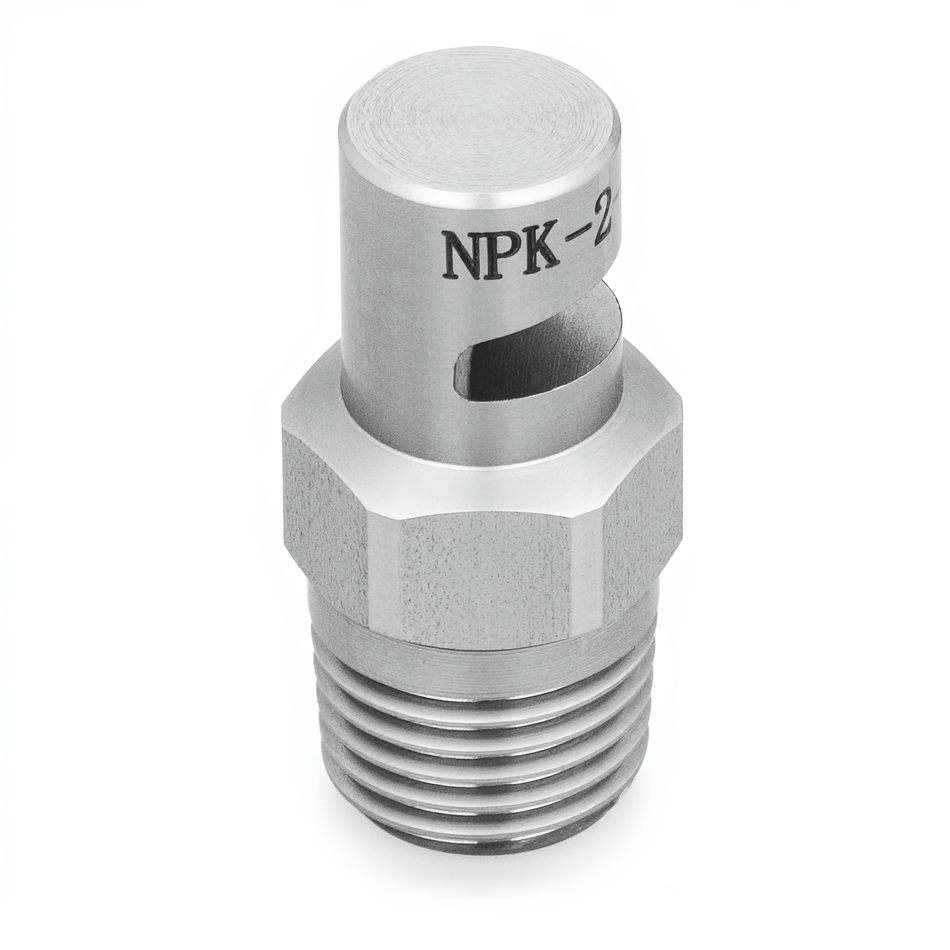

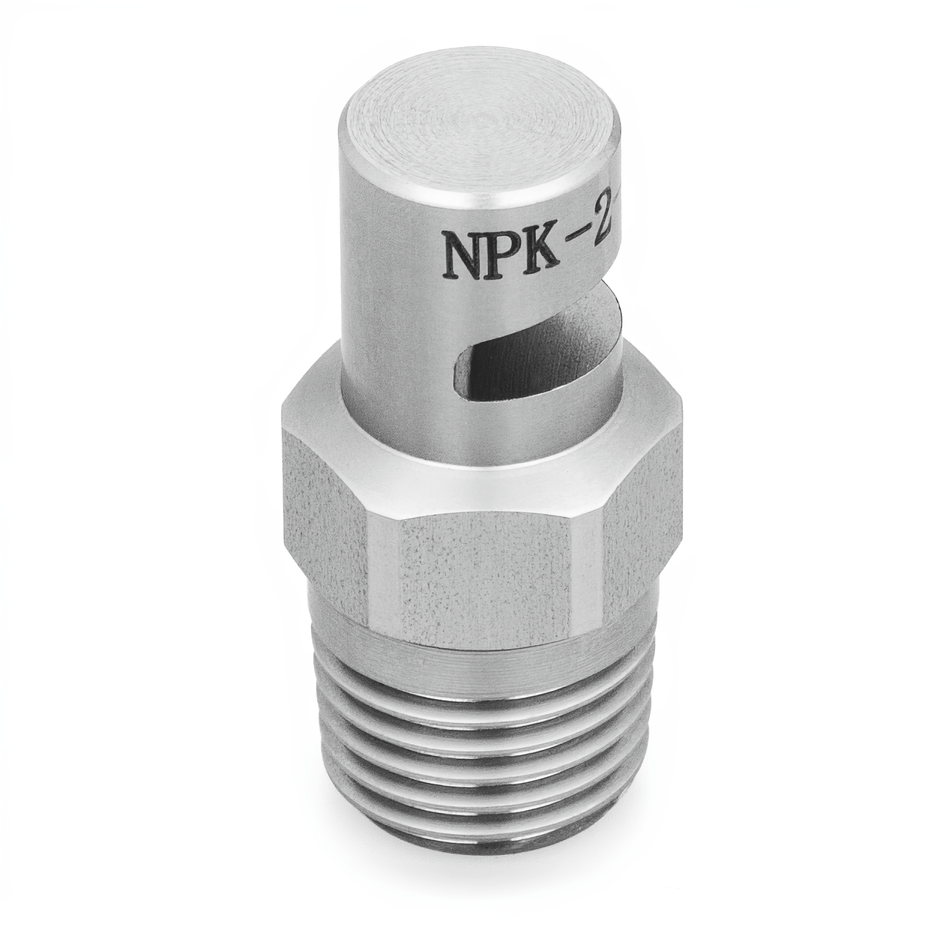

Product Parameters

| Product Family | Flat |

|---|---|

| Product Series | NPHVL |

| Capacity Size | 4 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | 316L stainless steel |

| Inlet Connection Size (in.) | 1/8 |

| Length (mm) | 36 |

| Length (in) | 1.531 |

| Hex Size (mm) | 12.7 |

| Hex Size (in) | 1/2 |

| Equivalent Orifice Diameter (in) | 0.05 |

| Spray Angle at Rated Pressure (PSI) | 50 |

| Equivalent Orifice Diameter (mm) | 1.3 |

Description

Product Overview

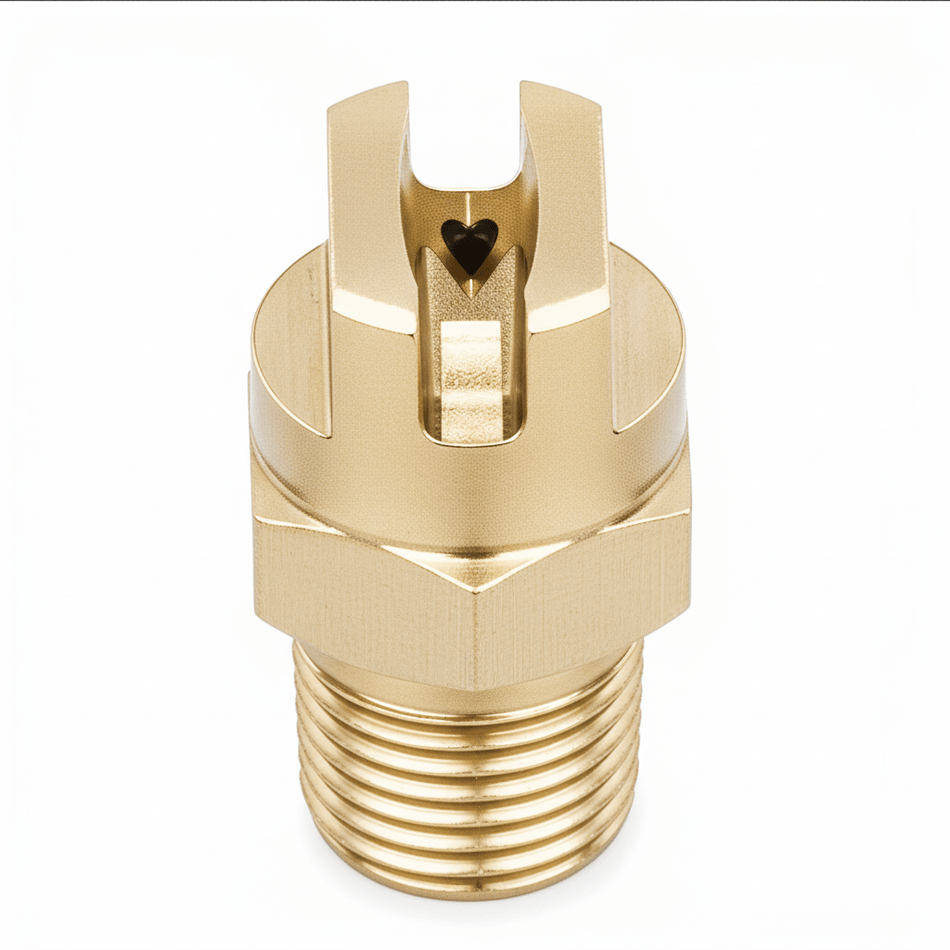

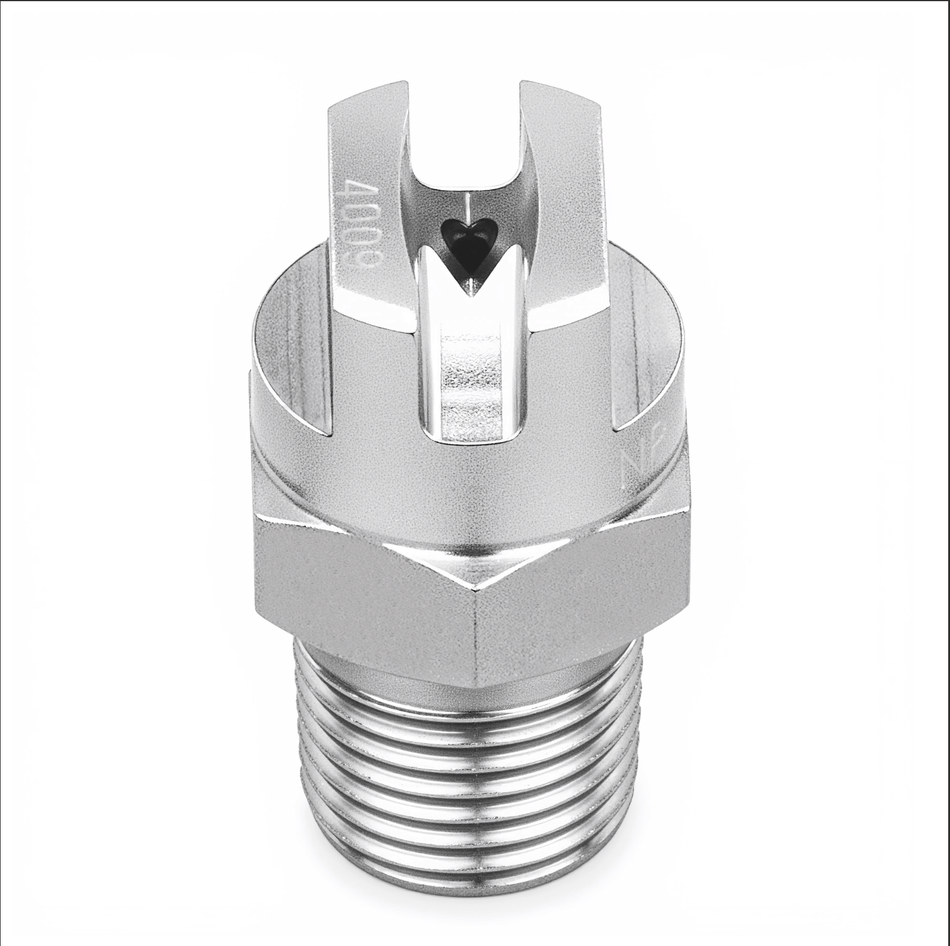

Inside the building materials line's cooling & quenching stage, a plant operator relies on the NPHVL-5004-1/8-316 to deliver a consistent flat spray that evenly covers metal surfaces during rapid cooling cycles. Constructed from 316L stainless steel, the nozzle withstands harsh environments and resists corrosion from water and chemical exposure. The uniform spray pattern minimizes hotspots and enhances thermal control, improving product quality and reducing rework. This precise distribution helps maintain process stability under continuous operation.

Applications

The nozzle's role in cooling & quenching ensures controlled temperature reduction critical to metallurgical properties and surface integrity. Additionally, its use in cleaning & washing applications removes residues and contaminants effectively, supporting downstream finishing and coating processes with minimal downtime.

Industries

Sectors such as automotive, steel & metals, and cement favor the NPHVL-5004-1/8-316 for its durability and spray consistency, which are essential for maintaining tight process tolerances. Food & beverage and breweries & wineries also utilize this nozzle for its corrosion resistance and uniform coverage, enhancing sanitation and operational reliability.