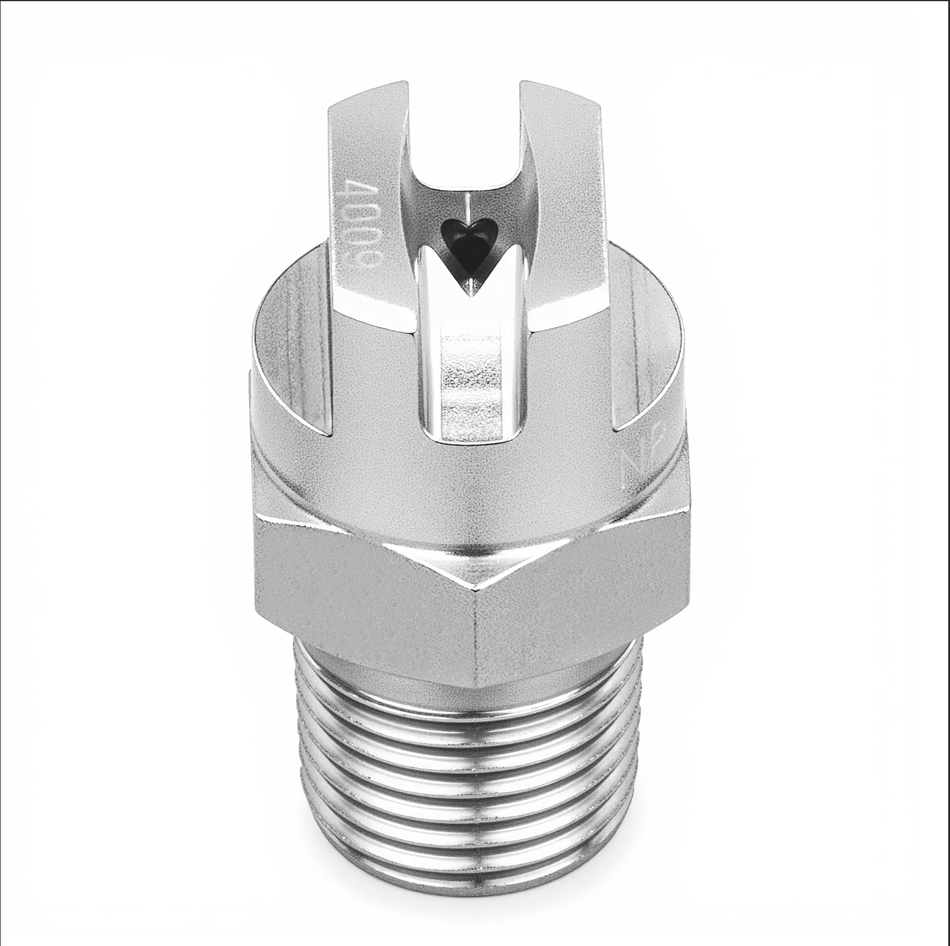

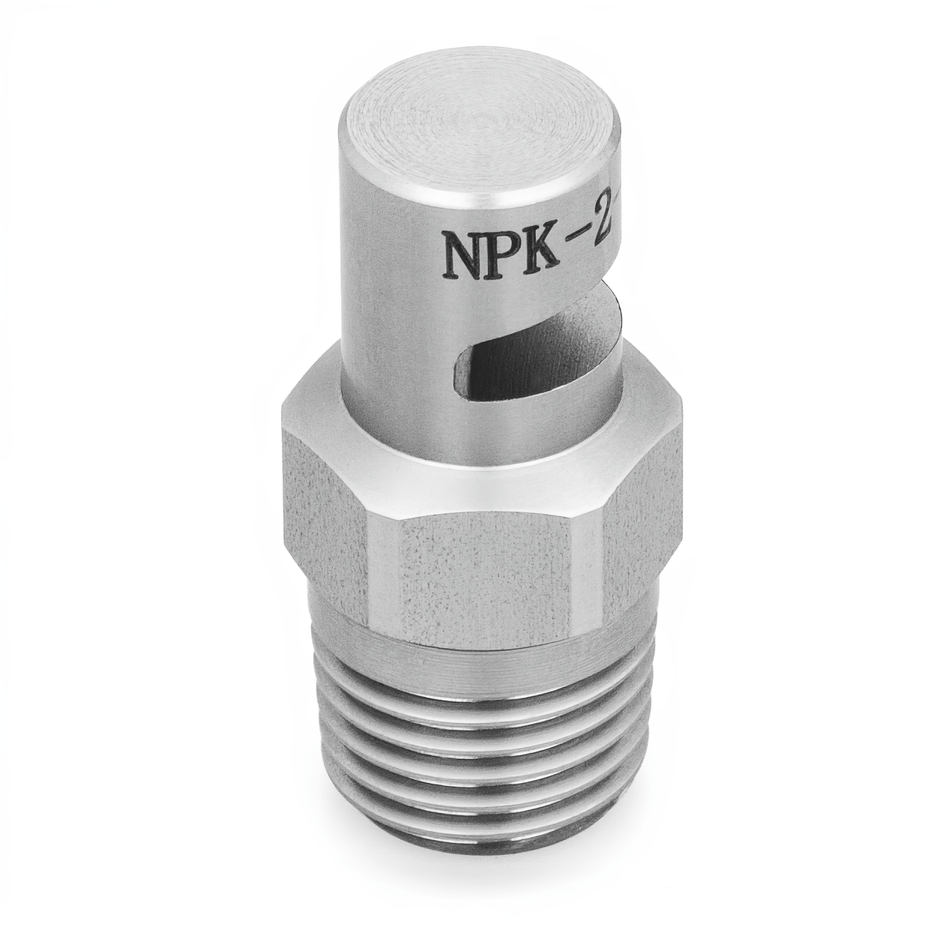

Product Parameters

| Product Family | Flat |

|---|---|

| Product Series | NPHVL |

| Capacity Size | 4 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | 316L stainless steel |

| Inlet Connection Size (in.) | 1/4 |

| Length (mm) | 38 |

| Length (in) | 1.250 |

| Hex Size (mm) | 14.3 |

| Hex Size (in) | 9/16 |

| Equivalent Orifice Diameter (in) | 0.05 |

| Spray Angle at Rated Pressure (PSI) | 25 |

| Equivalent Orifice Diameter (mm) | 1.3 |

Description

Product Overview

Inside the beverage bottling & packaging line's cooling & quenching stage, a maintenance supervisor relies on the NPHVL-2504-1/4-316 to deliver consistent spray coverage that protects equipment from overheating. Constructed from 316L stainless steel, the nozzle withstands corrosive environments common to washdown and fluid cooling processes. Its flat spray pattern ensures uniform distribution across conveyor surfaces, reducing thermal variation and extending component service life. The supervisor routinely checks flow rates and spray angles to maintain process stability and minimize downtime.

Applications

The nozzle plays a critical role in cleaning & washing operations by providing effective surface wetting that aids in the removal of residues and contaminants. Additionally, cooling & quenching applications benefit from its precise spray pattern, which helps control temperature fluctuations during sensitive production stages.

Industries

Sectors such as automotive, mining, and steel & metals incorporate this nozzle to meet their corrosion resistance and spray uniformity demands. Building materials, food & beverage, and Energy industries also depend on this component to achieve consistent output in coating & surface treatment and specialty application processes.