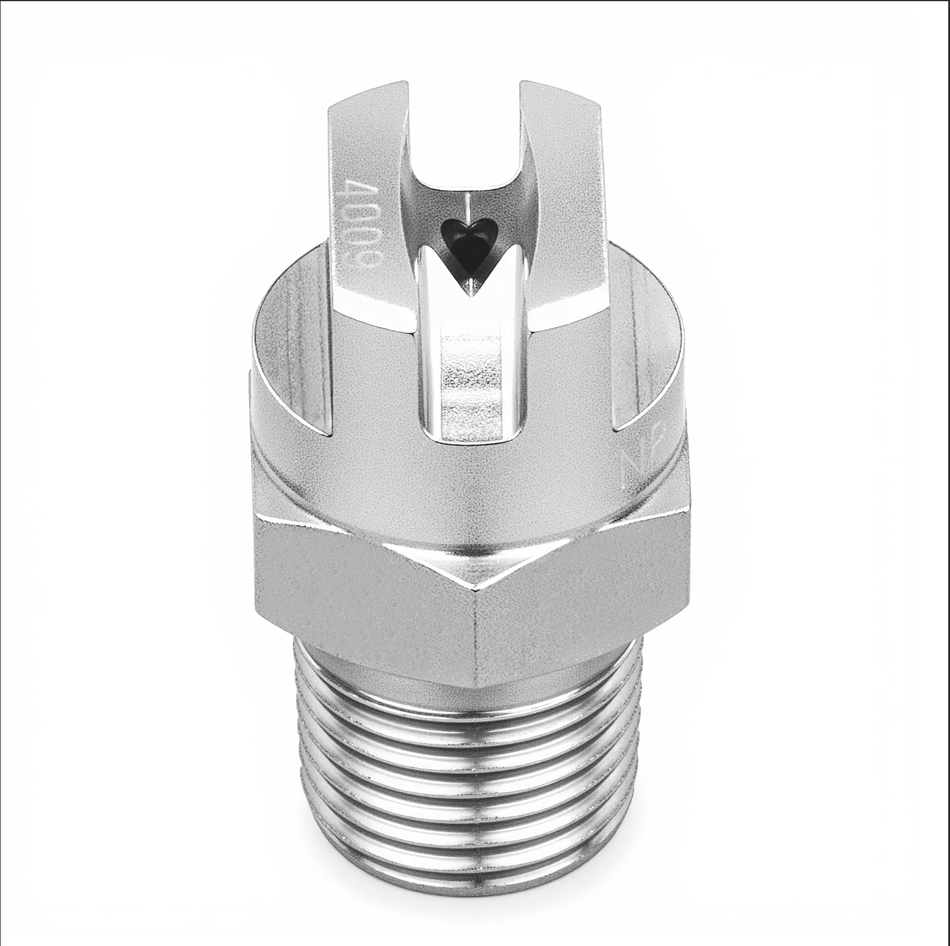

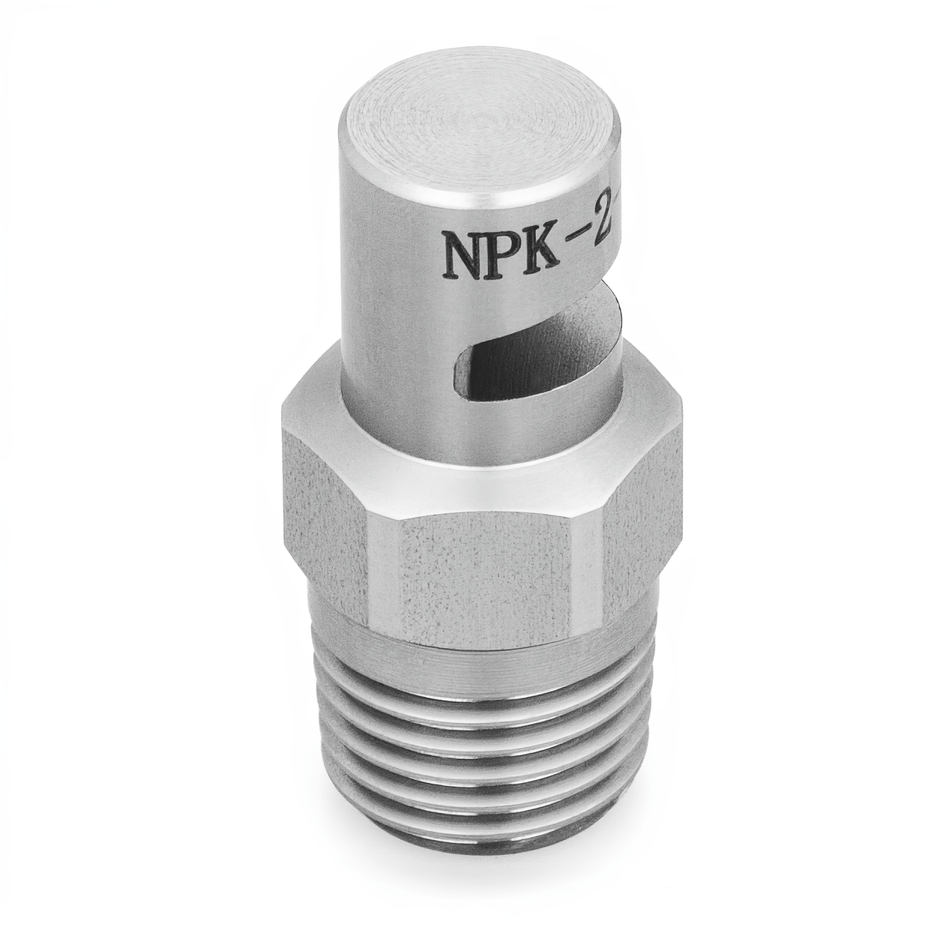

Product Parameters

| Product Family | Flat |

|---|---|

| Product Series | NPHVL |

| Capacity Size | 8 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | 316L stainless steel |

| Inlet Connection Size (in.) | 1/4 |

| Length (mm) | 38 |

| Length (in) | 1.250 |

| Hex Size (mm) | 14.3 |

| Hex Size (in) | 9/16 |

| Equivalent Orifice Diameter (in) | 0.071 |

| Spray Angle at Rated Pressure (PSI) | 110 |

| Equivalent Orifice Diameter (mm) | 1.8 |

Description

Product Overview

Inside the engineered wood line's cooling & quenching stage, a process engineer relies on the NPHVL-11008-1/4-316 to deliver consistent flat spray coverage essential for uniform temperature control. Constructed from 316L stainless steel, the nozzle resists corrosion caused by water and chemical exposure, extending service life under continuous operation. The 1/4-inch inlet facilitates seamless integration with existing piping, while the precision flat spray ensures optimal fluid distribution, reducing thermal gradients and improving product quality. This targeted application helps maintain process stability and reduces downtime for maintenance.

Applications

In cooling & quenching processes, the nozzle supports controlled temperature reduction to preserve material properties and prevent structural defects. Additionally, its use in cleaning & washing systems contributes to efficient removal of residues, enhancing equipment uptime and process hygiene.

Industries

Sectors such as mining, steel & metals, and automotive depend on the nozzle's corrosion resistance and uniform spray for managing harsh operating conditions. Food & beverage facilities along with breweries & wineries benefit from its sanitary construction and consistent fluid application to meet strict quality standards.