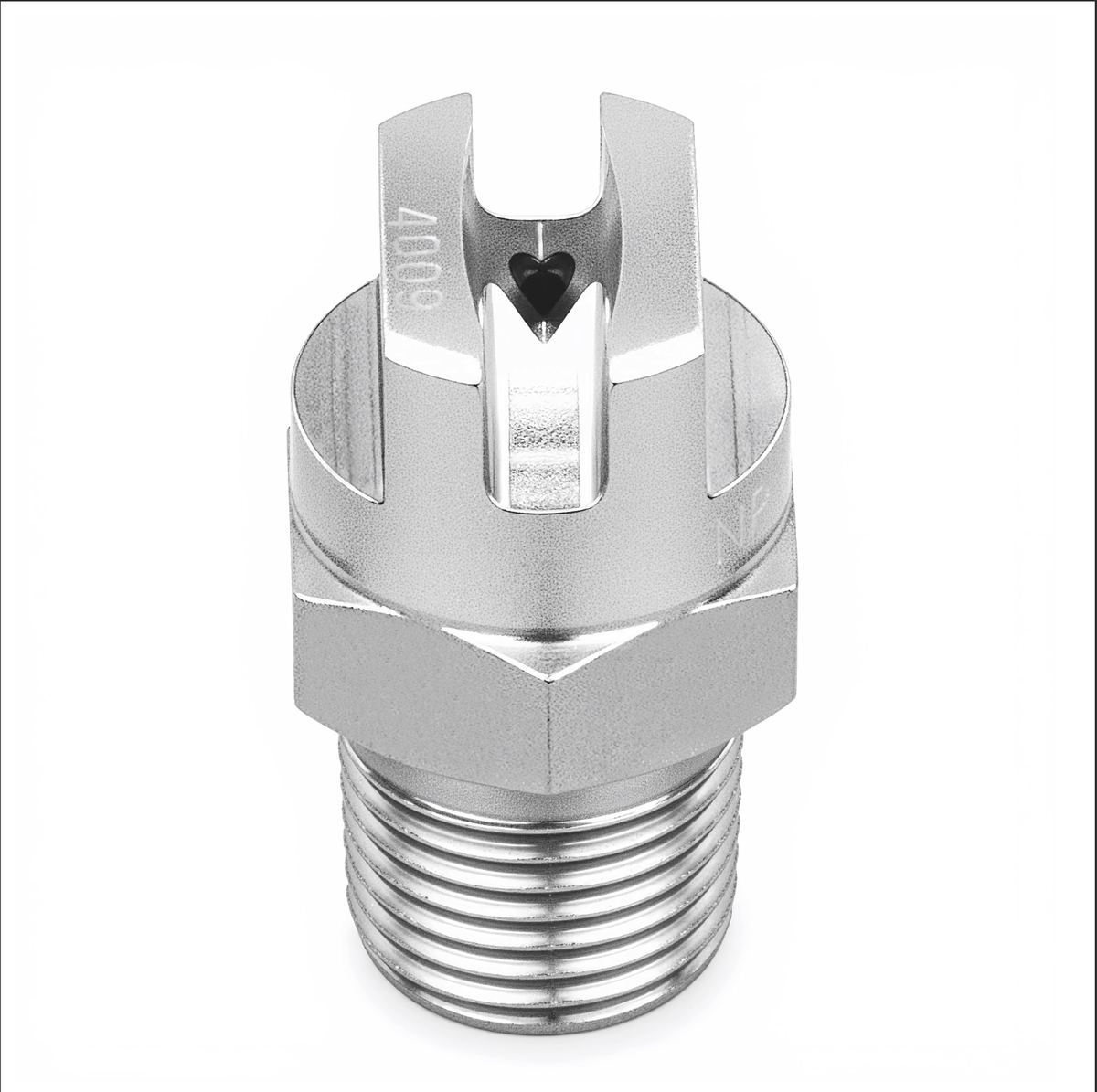

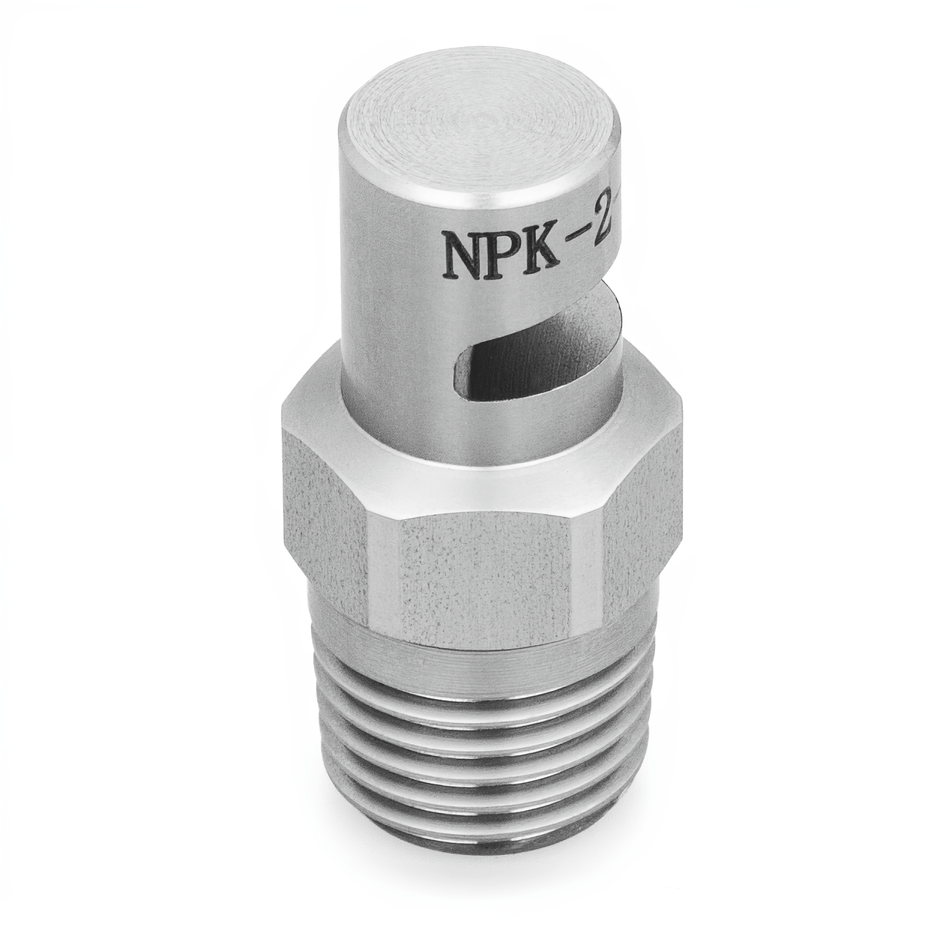

Product Parameters

| Product Family | Flat |

|---|---|

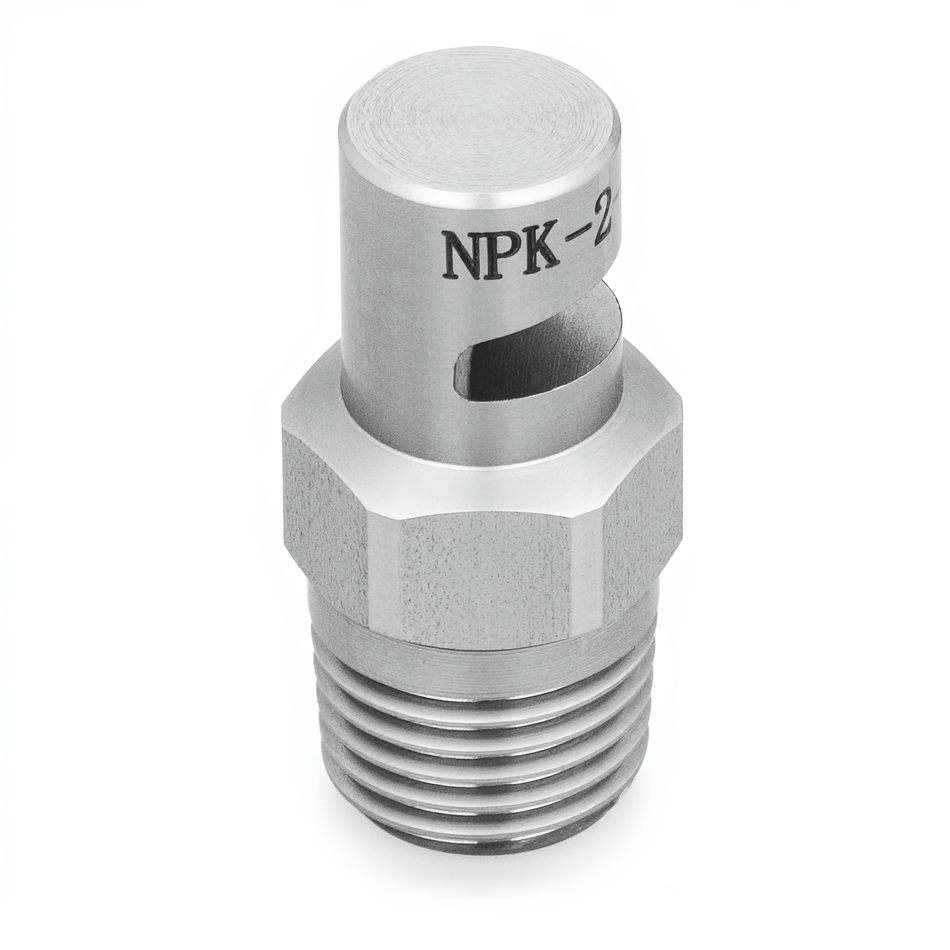

| Product Series | NPHV |

| Capacity Size | 4 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | 316L stainless steel |

| Inlet Connection Size (in.) | 1/8 |

| Length (mm) | 22 |

| Length (in) | 0.875 |

| Hex Size (mm) | 12.7 |

| Hex Size (in) | 1/2 |

| Equivalent Orifice Diameter (in) | 0.05 |

| Spray Angle at Rated Pressure (PSI) | 95 |

| Equivalent Orifice Diameter (mm) | 1.3 |

Description

Product Overview

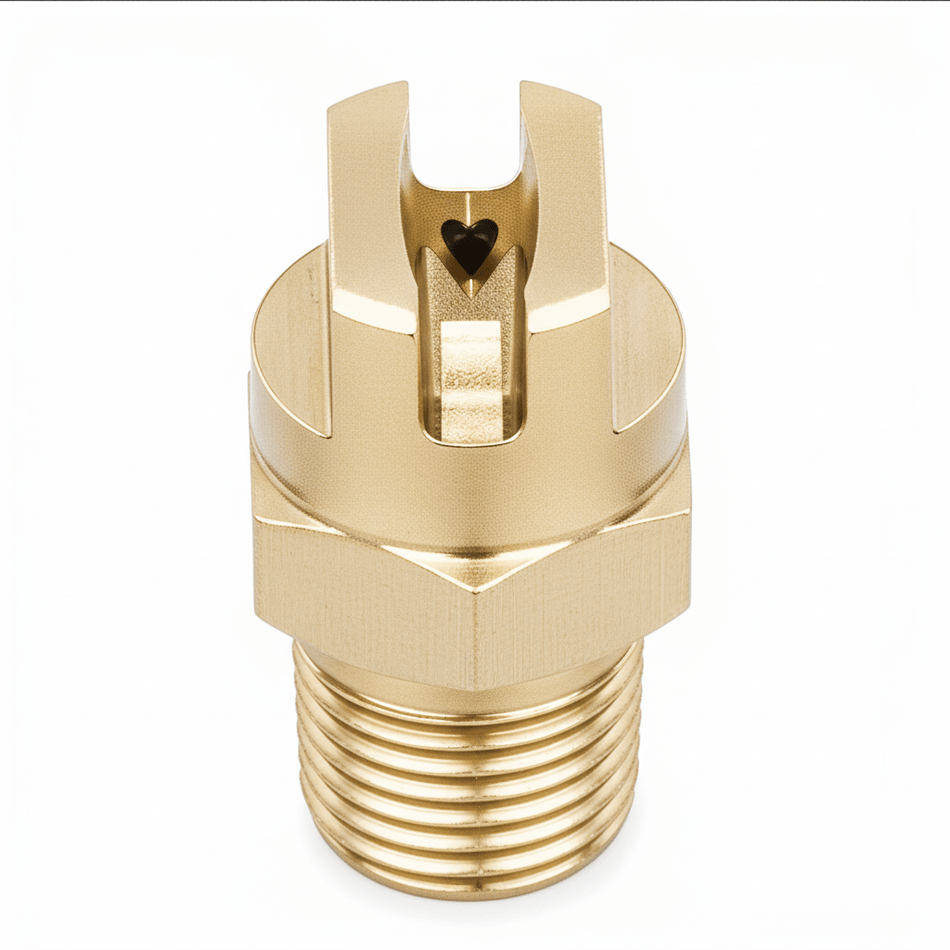

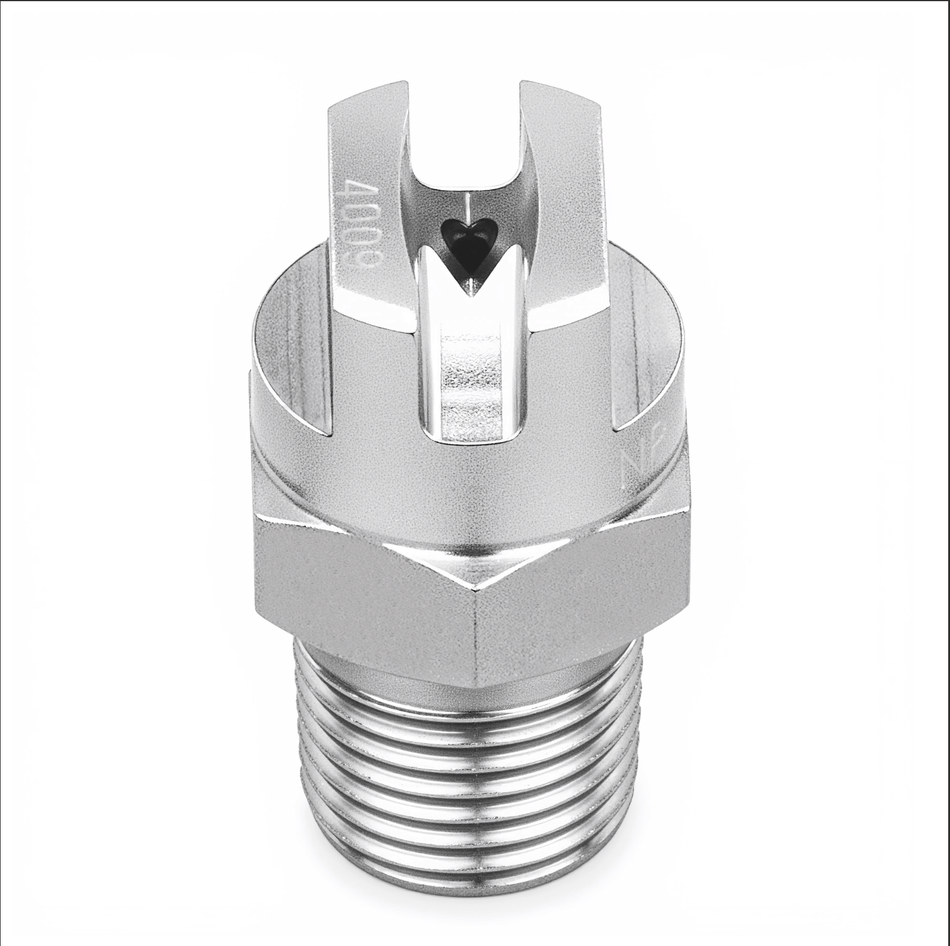

A plant operator in the manufacturing & assembly facility uses the NPHV-9504-1/8-316 during cooling & quenching to deliver a consistent, flat spray that ensures even temperature reduction on metal components. Constructed from 316L stainless steel, the nozzle withstands corrosion typically encountered in harsh processing environments. The operator connects the 1/8-inch inlet to standard fluid lines, enabling uniform fluid distribution and reducing thermal stress on parts. This precise control of spray coverage helps maintain product integrity and minimizes rework due to uneven cooling.

Applications

In cooling & quenching operations, the flat spray pattern from the nozzle ensures rapid and uniform heat dissipation, directly impacting cycle times and product quality. The nozzle also supports dust & pollution control by efficiently wetting surfaces to suppress airborne particulates, which reduces environmental emissions and improves workplace safety.

Industries

Sectors such as automotive, steel & metals, and cement favor this nozzle for its corrosion resistance and reliable spray uniformity under continuous use. Additionally, food & beverage and beverage bottling & packaging industries benefit from its material compatibility and precise flow control during cleaning & washing processes.