Description

Specifications

Applications

Industries

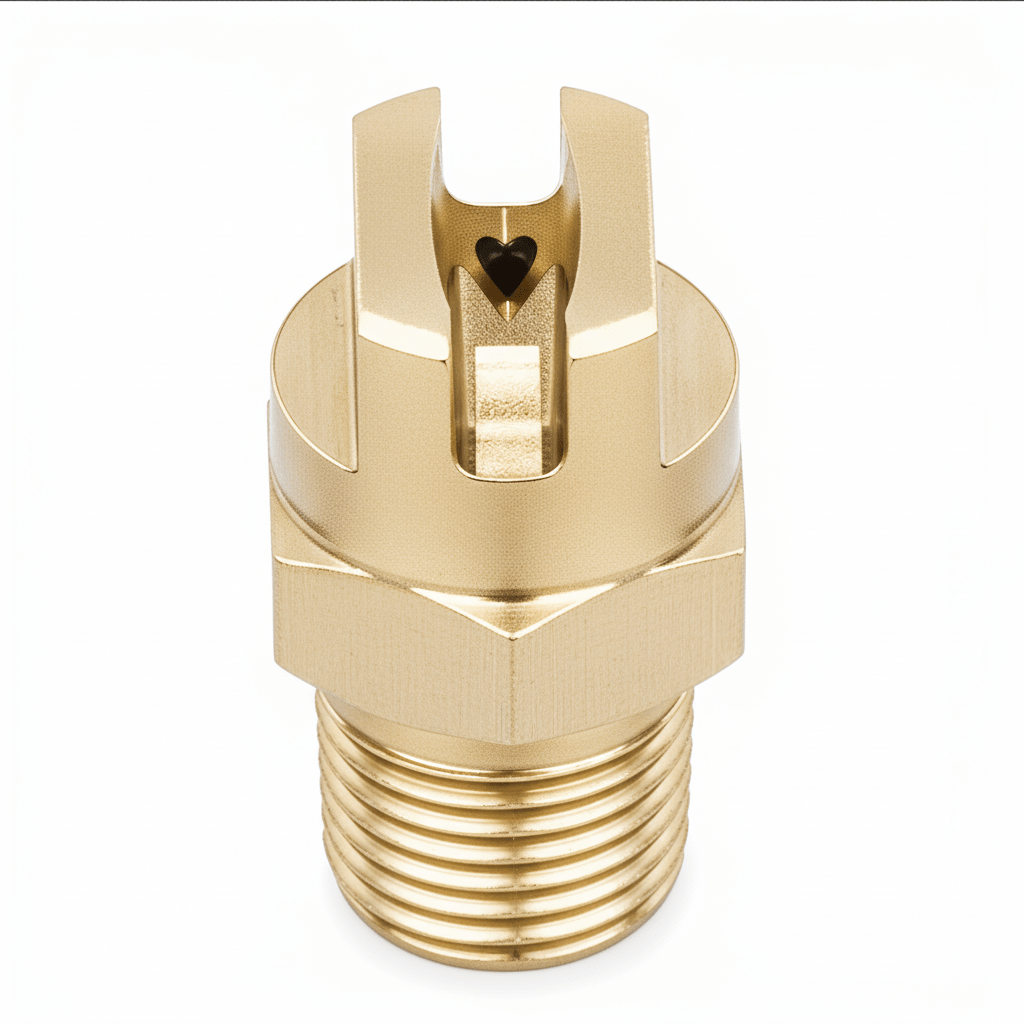

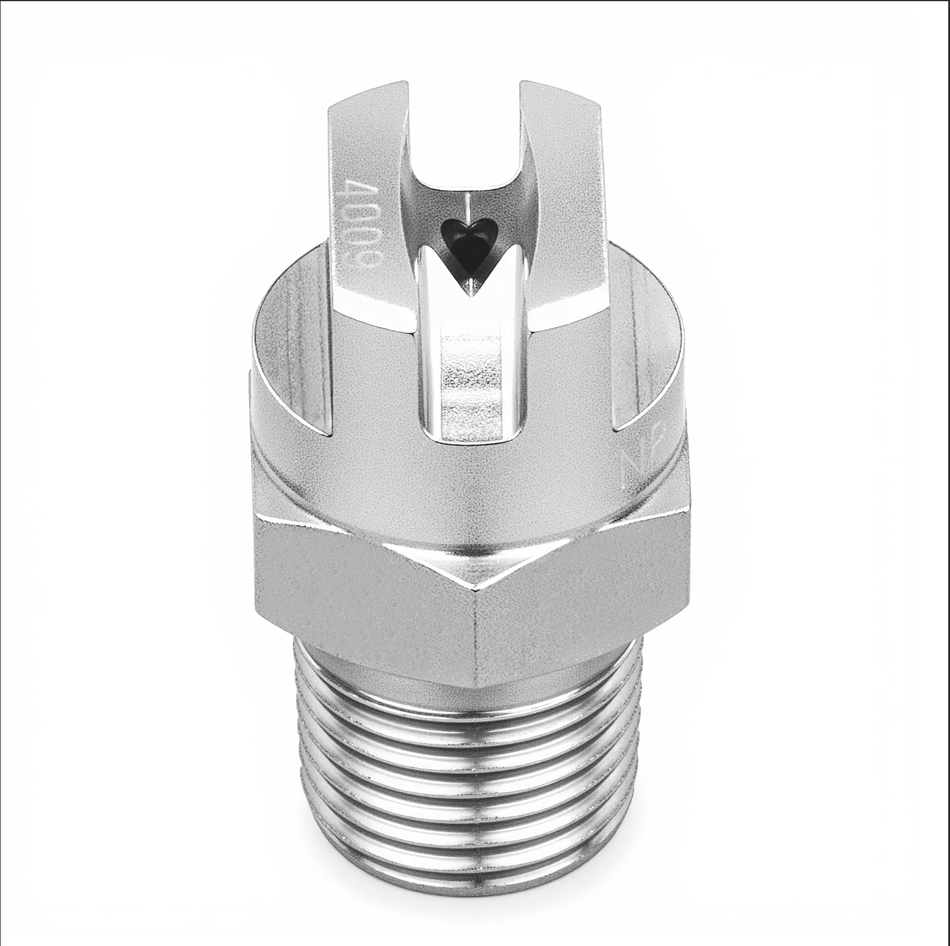

The NPHV-6503-1/4 flat nozzle is manufactured from Brass. Capacity Size: 3. Inlet: 1/4" NPT. Spray angle: 65° at rated pressure.

Please see the Specifications tab for detailed dimensions and configuration details.

Product Family

Flat

Product Series

NPHV

Capacity Size

3

Inlet Connection Thread Type

NPT

Material Composition Filter

Brass

Inlet Connection Size (in.)

1/4

Length (mm)

23

Length (in)

0.906

Hex Size (mm)

14.3

Hex Size (in)

9/16

Equivalent Orifice Diameter (in)

0.043

Spray Angle at Rated Pressure (PSI)

65

Equivalent Orifice Diameter (mm)

1.1

Cleaning & Washing Cooling & Quenching Dust & Pollution Control Coating & Surface Treatment Specialty Applications Car Wash Trucking & Fleet Wash

Automotive Building Materials Energy Food & Beverage Mining Steel & Metals Bakery & Confectionery Beverage Bottling & Packaging Breweries & Wineries Cement Dairy Engineered Wood Manufacturing & Assembly Meat & Poultry Roofing