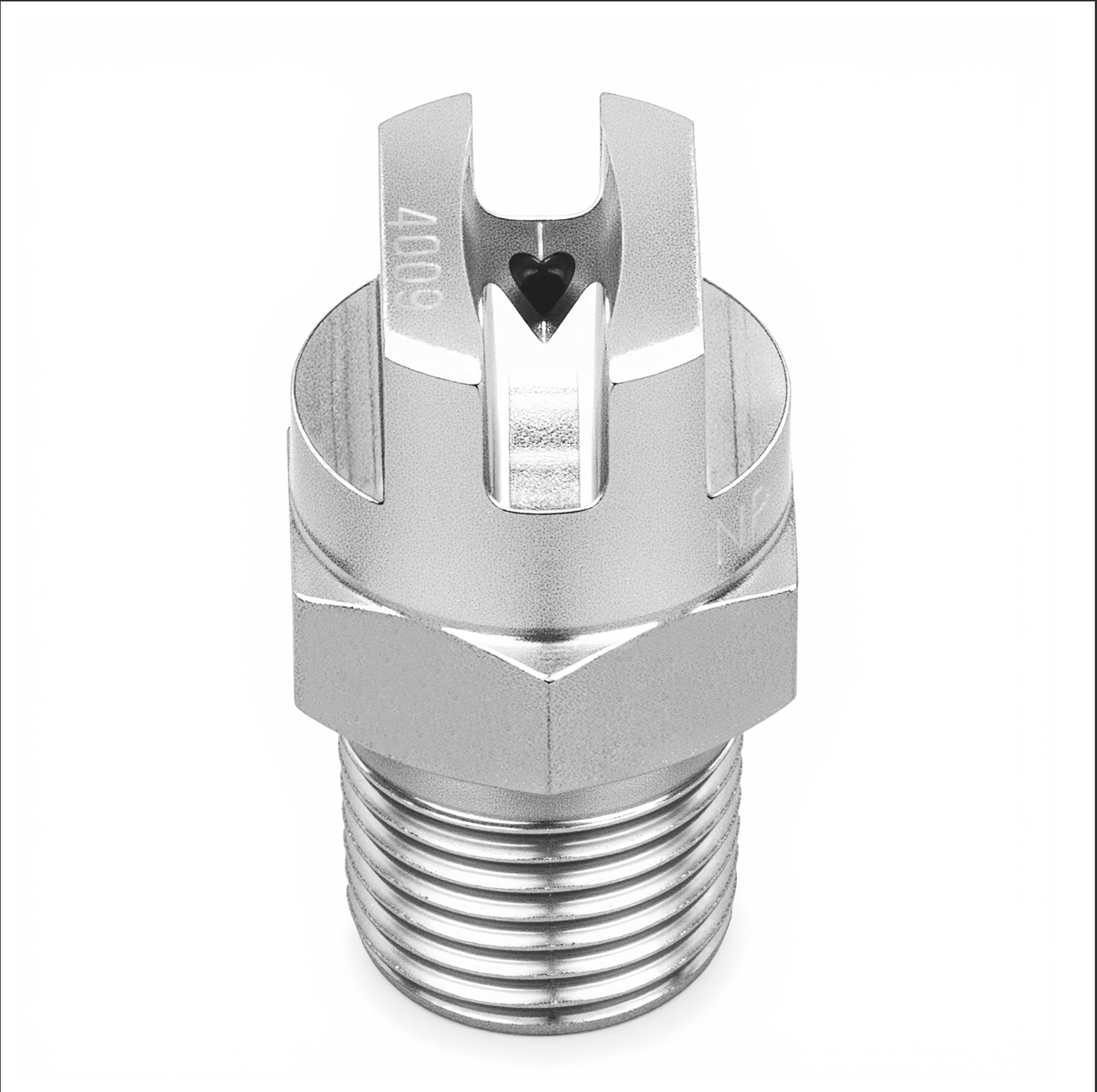

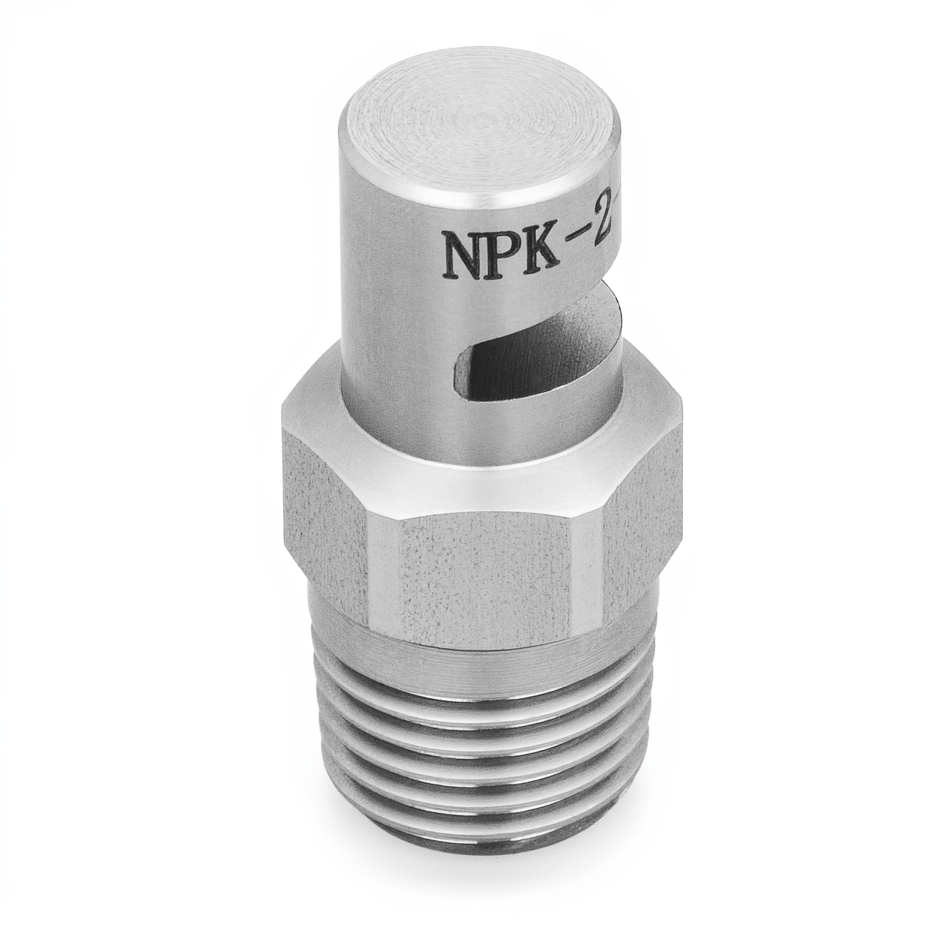

Product Parameters

| Product Family | Flat |

|---|---|

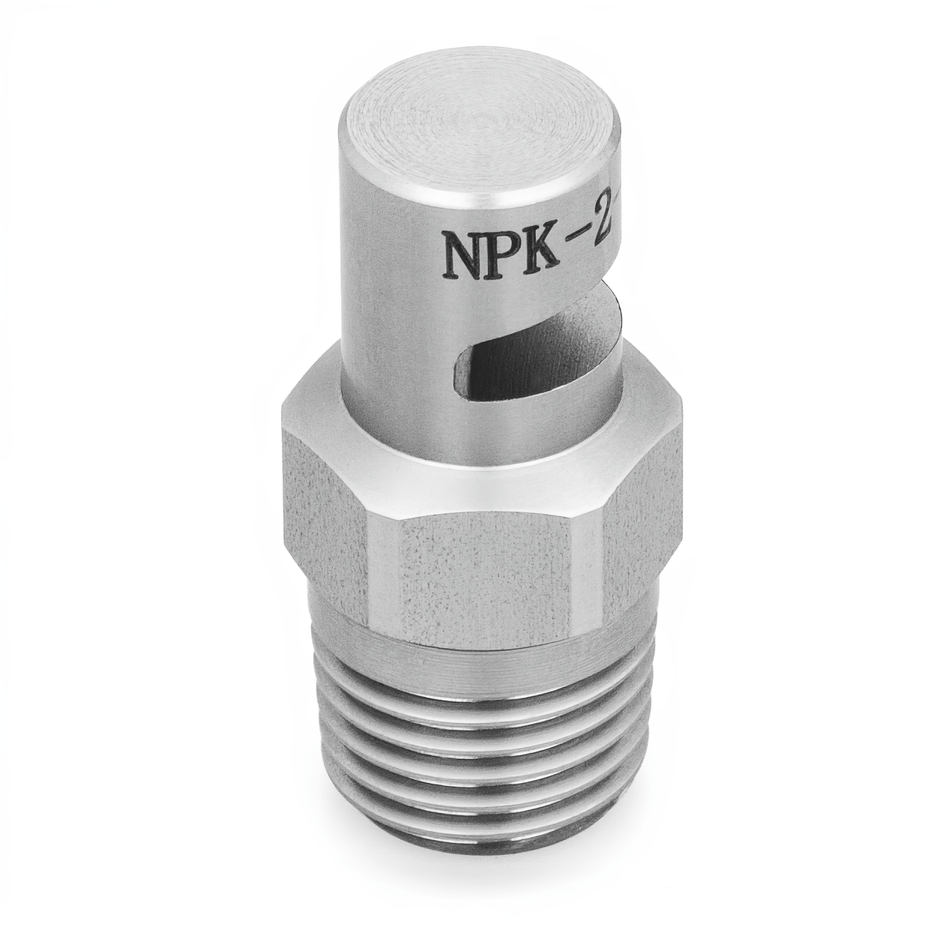

| Product Series | NPHV |

| Capacity Size | 1 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | 316L stainless steel |

| Inlet Connection Size (in.) | 1/4 |

| Length (mm) | 23 |

| Length (in) | 0.906 |

| Hex Size (mm) | 14.3 |

| Hex Size (in) | 9/16 |

| Equivalent Orifice Diameter (in) | 0.026 |

| Spray Angle at Rated Pressure (PSI) | 15 |

| Equivalent Orifice Diameter (mm) | 0.66 |

Description

Product Overview

A production technician in the beverage bottling & packaging facility uses the NPHV-1501-1/4-316 during cooling & quenching to ensure consistent temperature control on bottles exiting the filler line. Constructed from 316L stainless steel, the nozzle resists corrosion from water and cleaning agents while delivering a flat, uniform spray pattern. This stable distribution optimizes cooling efficiency and reduces thermal stress on containers, improving throughput and minimizing material waste. The technician integrates the NPHV-1501-1/4-316 into existing spray systems with a 1/4-inch inlet connection, allowing straightforward replacement and maintenance.

Applications

In cleaning & washing, the nozzle's uniform flat spray pattern provides thorough surface coverage critical for sanitation and debris removal in packaging lines. For cooling & quenching tasks, its corrosion-resistant construction supports consistent operation under continuous use, which enhances process reliability and product quality downstream.

Industries

Sectors such as automotive, steel & metals, and manufacturing & assembly utilize this nozzle to meet strict operational demands involving fluid handling and surface treatment. Additionally, the food & beverage, bakery & confectionery, and dairy industries rely on the nozzle's material compatibility and spray precision for hygienic processing and temperature control.