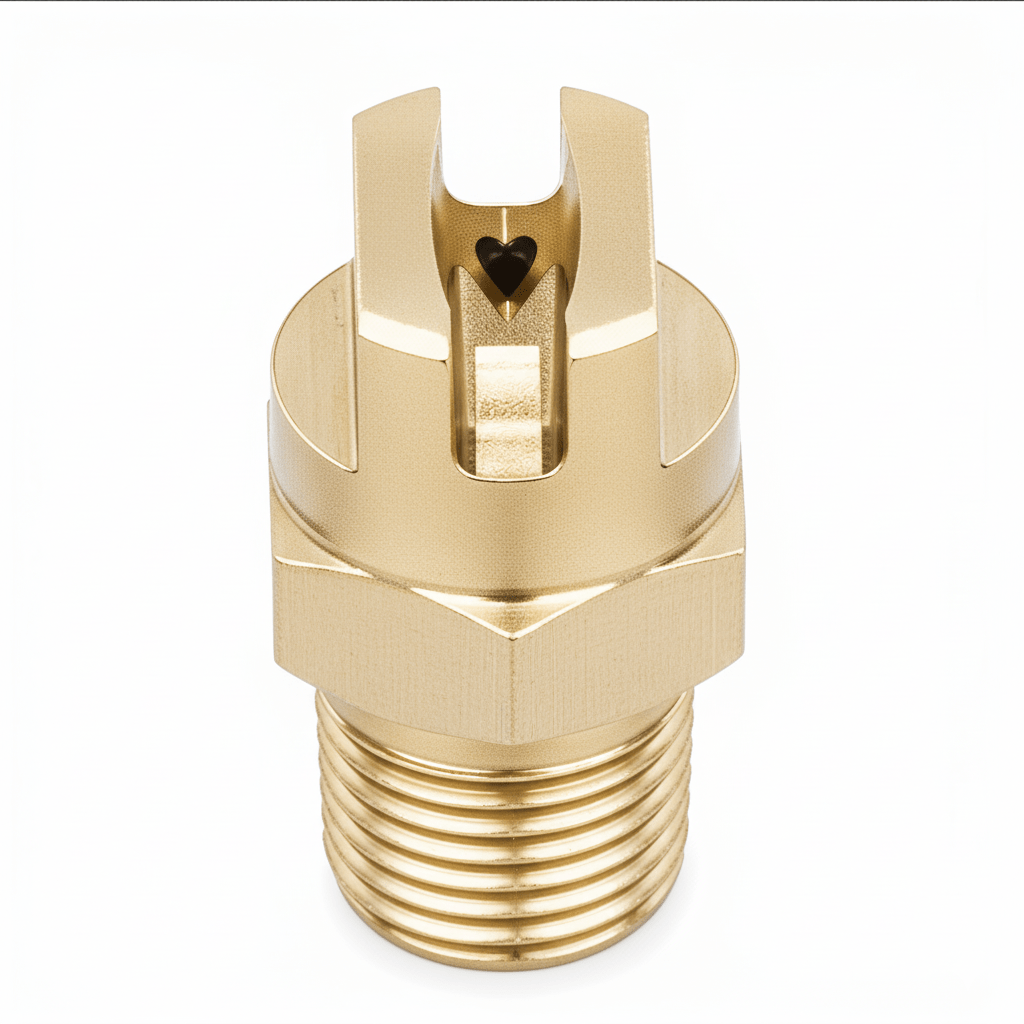

Product Parameters

| Product Family | Flat |

|---|---|

| Product Series | NPHV |

| Capacity Size | 15 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | Brass |

| Inlet Connection Size (in.) | 1/4 |

| Length (mm) | 23 |

| Length (in) | 0.906 |

| Hex Size (mm) | 14.3 |

| Hex Size (in) | 9/16 |

| Equivalent Orifice Diameter (in) | 0.094 |

| Spray Angle at Rated Pressure (PSI) | 110 |

| Equivalent Orifice Diameter (mm) | 0.81 |

Description

Product Overview

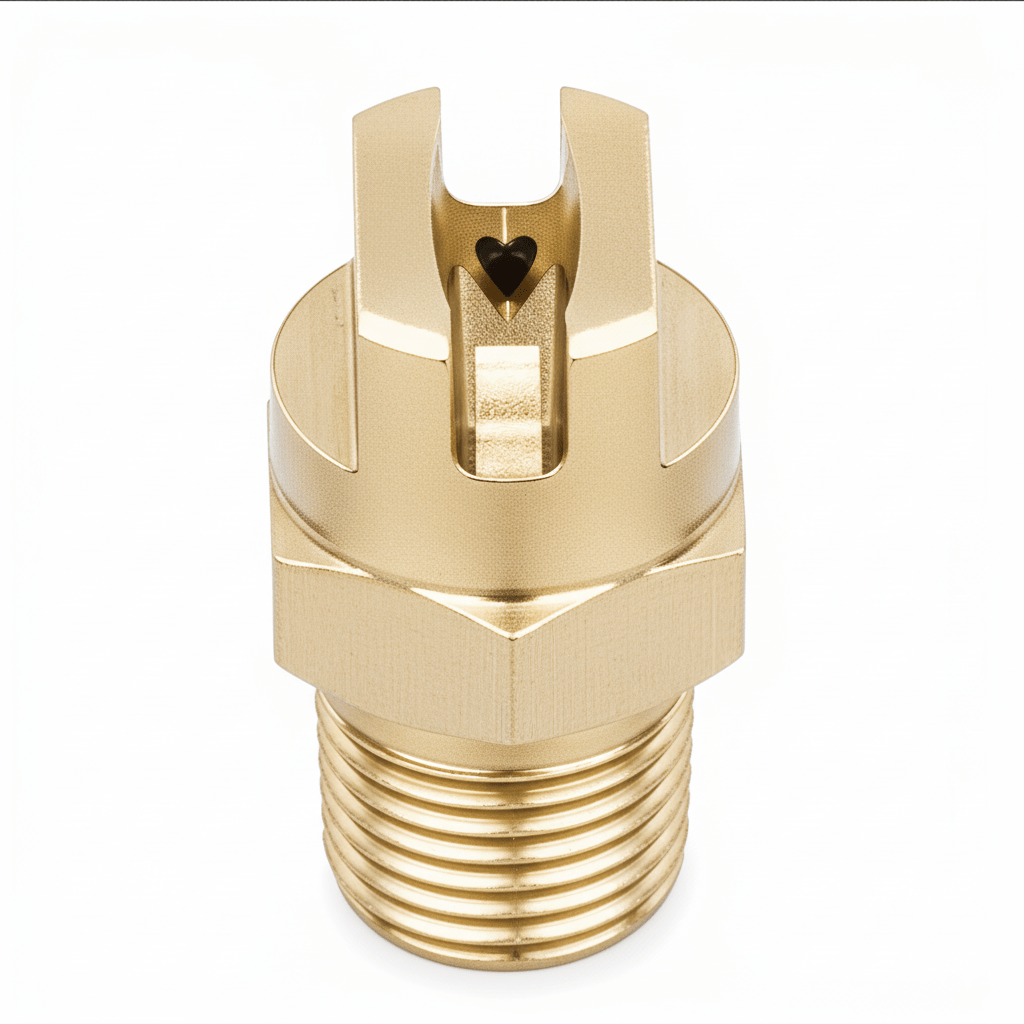

Inside the cement line's cooling & quenching stage, a plant operator relies on the NPHV-110015-1/4 to deliver consistent spray coverage critical for temperature control. Crafted from brass, the nozzle resists corrosion from harsh process water, ensuring longevity under continuous operation. Its precision flat spray pattern allows for uniform fluid distribution, reducing hot spots and improving product quality. The operator monitors flow rates and spray angle to maintain optimal cooling efficiency throughout the production cycle.

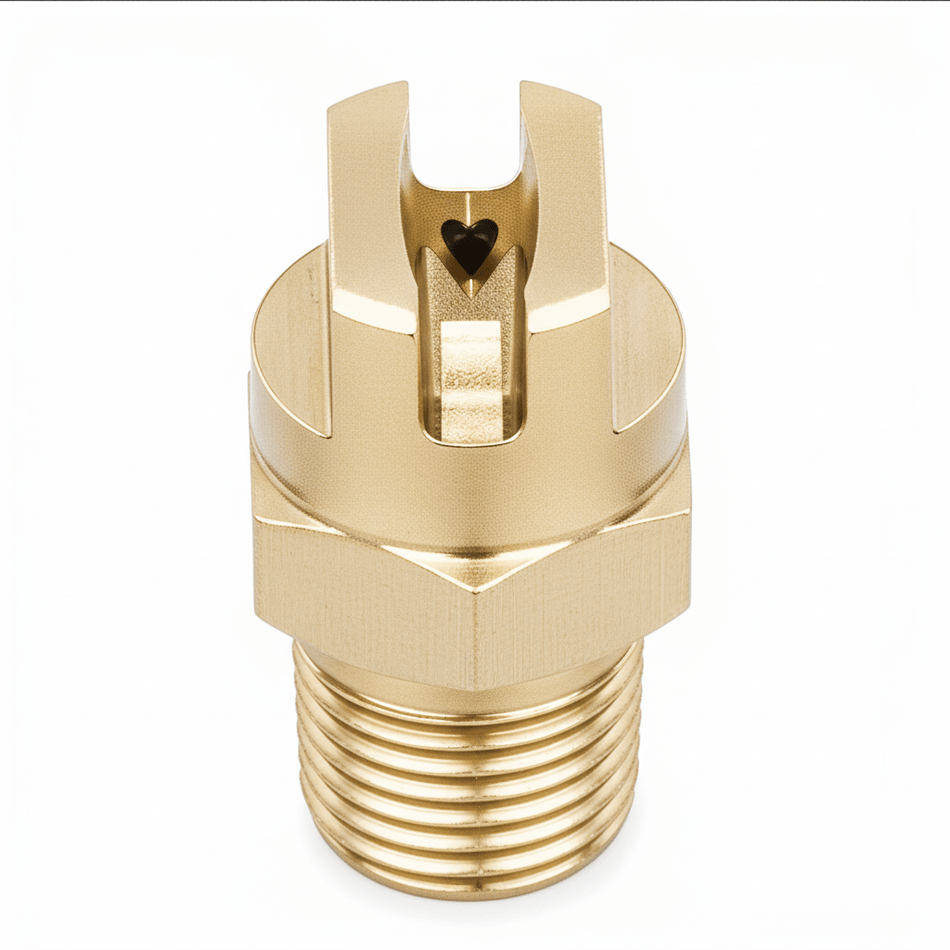

Applications

During cleaning & washing procedures, this nozzle ensures thorough surface coverage, minimizing residue and downtime in the cement process. Its role in cooling & quenching extends to controlling dust and reducing airborne particulates, which contributes to safer working conditions and regulatory compliance.

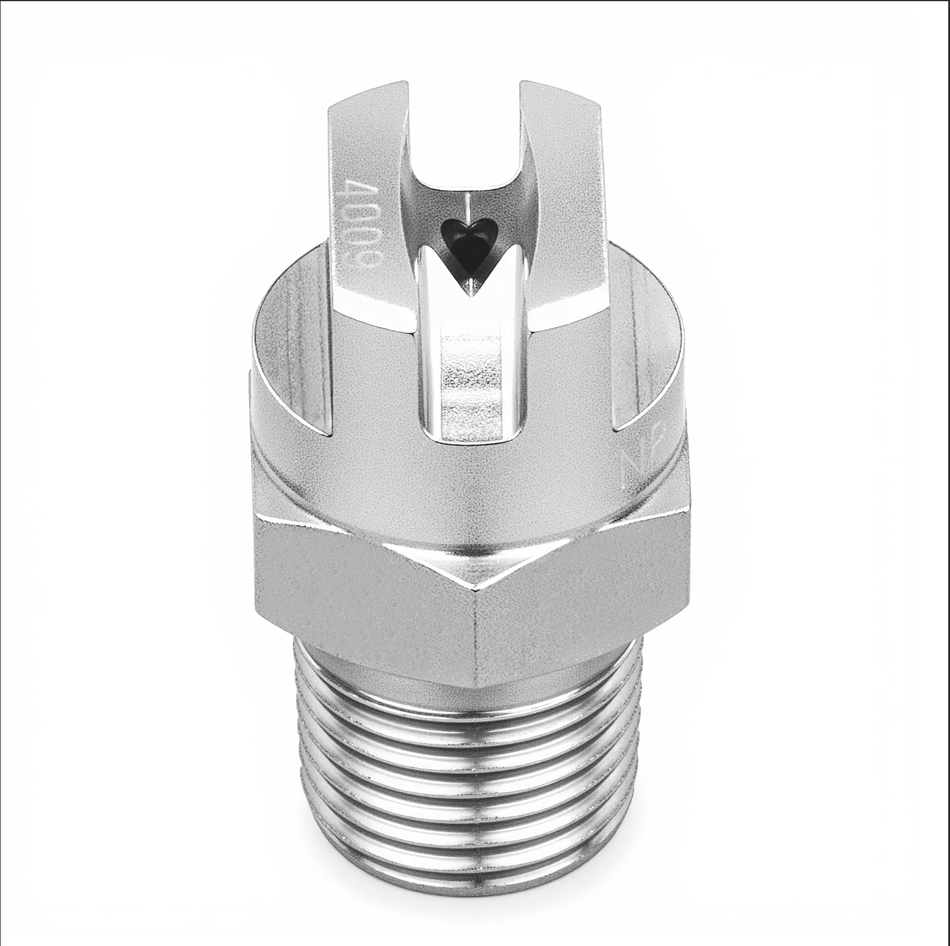

Industries

The NPHV-110015-1/4 is favored in sectors such as automotive, mining, steel & metals, and Energy for its durability and consistent spray performance. Facilities in food & beverage, building materials, and manufacturing & assembly also utilize this nozzle to maintain process integrity under demanding operational conditions.