Product Parameters

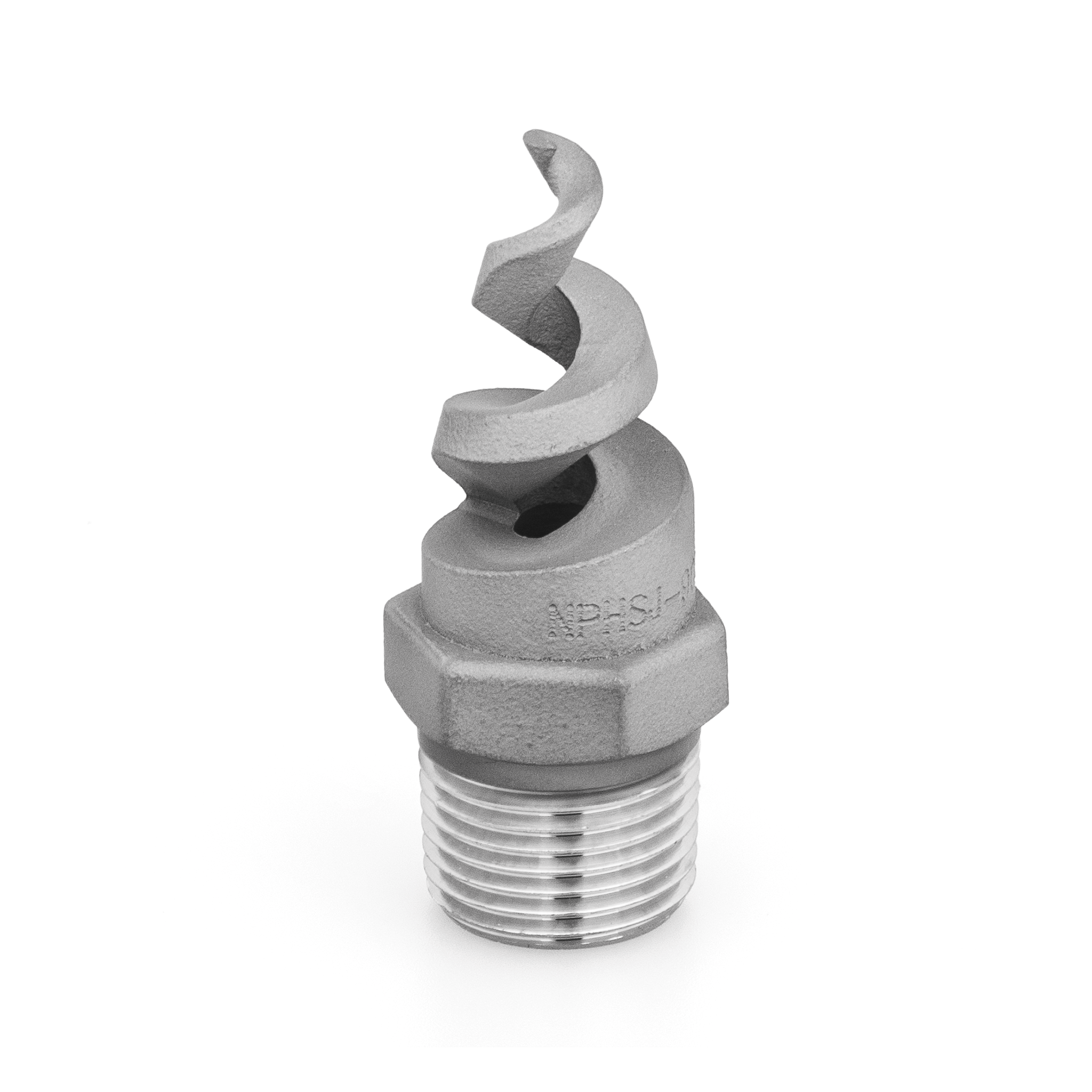

| Product Family | Full Cone Spiral |

|---|---|

| Product Series | NPHSJ |

| Capacity Size | 5250 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (in) | 2.5 |

| Inlet Connection Size (in.) | 1 |

| Length (mm) | 116 |

| Length (in) | 9.000 |

| Hex Size (mm) | 34.9 |

| Hex Size (in) | 4-1/2 |

| Spray Angle at Rated Pressure (PSI) | 90 |

Description

Product Overview

Inside the mining line's trucking & fleet wash stage, a process engineer relies on the NPHSJ-905250-4-316 to deliver consistent full cone spray coverage for thorough vehicle cleaning. Constructed from 316L stainless steel, the nozzle withstands corrosive environments commonly encountered in mineral processing operations. The spiral design produces a uniform distribution pattern that optimizes water usage and enhances surface contact, reducing residue buildup. This precision component ensures reliable performance under varied flow conditions, contributing to efficient wash cycles and minimized downtime.

Applications

In trucking & fleet wash operations, the NPHSJ-905250-4-316 supports effective cleaning & washing by providing a stable spray that removes dirt and contaminants without damaging vehicle surfaces. Additionally, its capability in dust & pollution control applications helps maintain environmental compliance by suppressing airborne particles generated during wash and transport stages.

Industries

The NPHSJ-905250-4-316 is favored across industries such as building materials, chemical processing, and mining due to its corrosion resistance and uniform spray characteristics. Sectors like steel & metals and breweries & wineries depend on this nozzle for consistent fluid distribution in manufacturing & assembly processes, where precise spray patterns are critical to operational reliability.