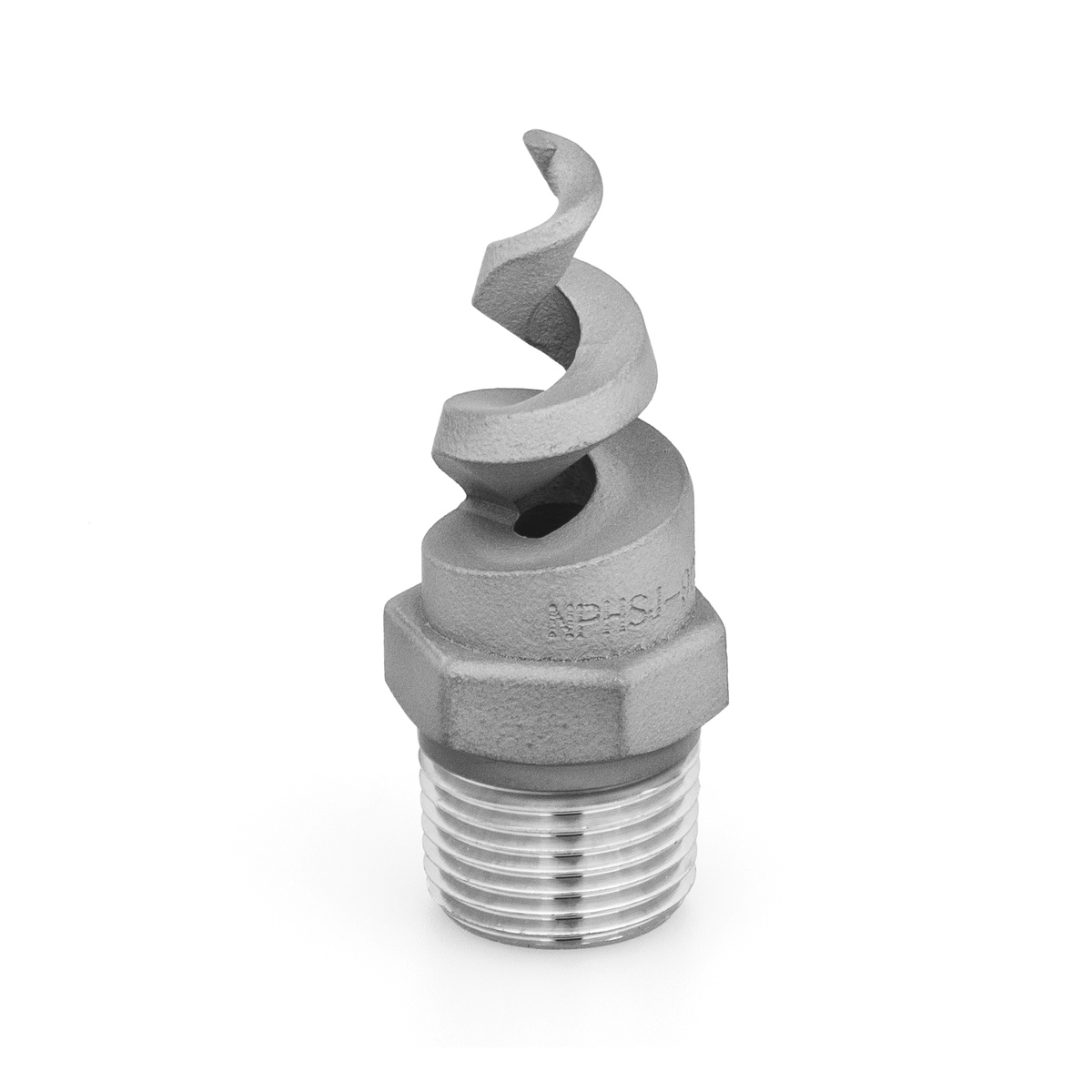

Product Parameters

| Product Family | Full Cone Spiral |

|---|---|

| Product Series | NPHSJ |

| Capacity Size | 5250 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (in) | 2.5 |

| Inlet Connection Size (in.) | 1 |

| Length (mm) | 116 |

| Length (in) | 9.000 |

| Hex Size (mm) | 34.9 |

| Hex Size (in) | 4-1/2 |

| Spray Angle at Rated Pressure (PSI) | 60 |

Description

Product Overview

During cleaning & washing on a chemical processing site, process engineers trust the NPHSJ-605250-4-316 to deliver consistent full cone coverage through its spiral design. Constructed from 316L stainless steel, this nozzle resists corrosion even in harsh chemical environments. Operators connect the 1-inch inlet to standard piping, ensuring uniform spray distribution that minimizes downtime and improves cleaning efficiency. The precision engineering behind the NPHSJ-605250-4-316 maintains stable flow rates critical for process control.

Applications

The nozzle's uniform spray pattern supports cleaning & washing operations by effectively removing residues and preventing buildup on equipment surfaces. In dust & pollution control scenarios, the consistent coverage helps suppress airborne particles, contributing to safer workplace environments and compliance with regulations.

Industries

Building materials, chemical processing, and Energy sectors rely on this nozzle for its durability and spray consistency, essential for maintaining operational integrity. Additionally, mining, steel & metals, and breweries & wineries favor the NPHSJ-605250-4-316 because it withstands corrosive conditions while supporting processes such as cooling & quenching and specialized fluid applications.