Product Parameters

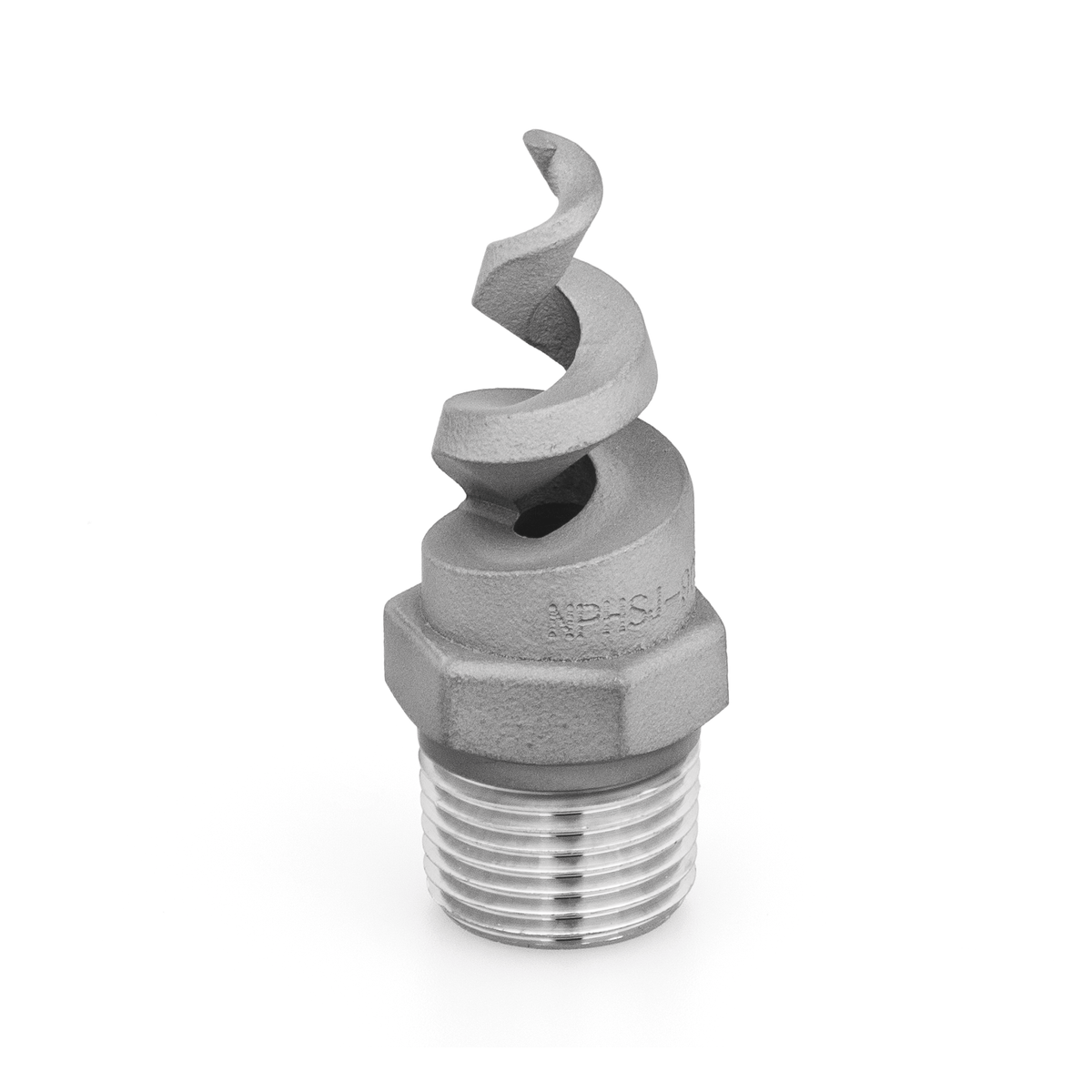

| Product Family | Full Cone Spiral |

|---|---|

| Product Series | NPHSJ |

| Capacity Size | 20 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 4.0 |

| Inlet Connection Size (in.) | 3/8 |

| Length (mm) | 60.3 |

| Length (in) | 1.875 |

| Hex Size (mm) | 17.5 |

| Hex Size (in) | 11/16 |

| Spray Angle at Rated Pressure (PSI) | 60 |

| Max. Free Passage Dia. (mm) | 3.2 |

Description

Product Overview

Inside the chemical processing line's cleaning & washing stage, a quality manager relies on the NPHSJ-6020-3/8-316 to deliver consistent spray coverage with minimal maintenance downtime. Constructed from 316L stainless steel, the nozzle resists corrosive agents commonly found in industrial environments. Its full cone, spiral design ensures uniform droplet distribution, which improves rinsing efficiency and reduces chemical usage. Operators observe measurable reductions in residue buildup, contributing to smoother production cycles.

Applications

The NPHSJ-6020-3/8-316 is frequently employed in cleaning & washing processes where uniform spray patterns help remove contaminants effectively. This precise spray control also supports dust & pollution control initiatives by suppressing airborne particulates during material handling and processing stages.

Industries

Sectors such as building materials, chemical processing, mining, and steel & metals often specify this nozzle for its durability and consistent performance under harsh conditions. Breweries & wineries, dairy, and manufacturing & assembly operations utilize it to maintain process cleanliness and meet stringent sanitary standards.