Product Parameters

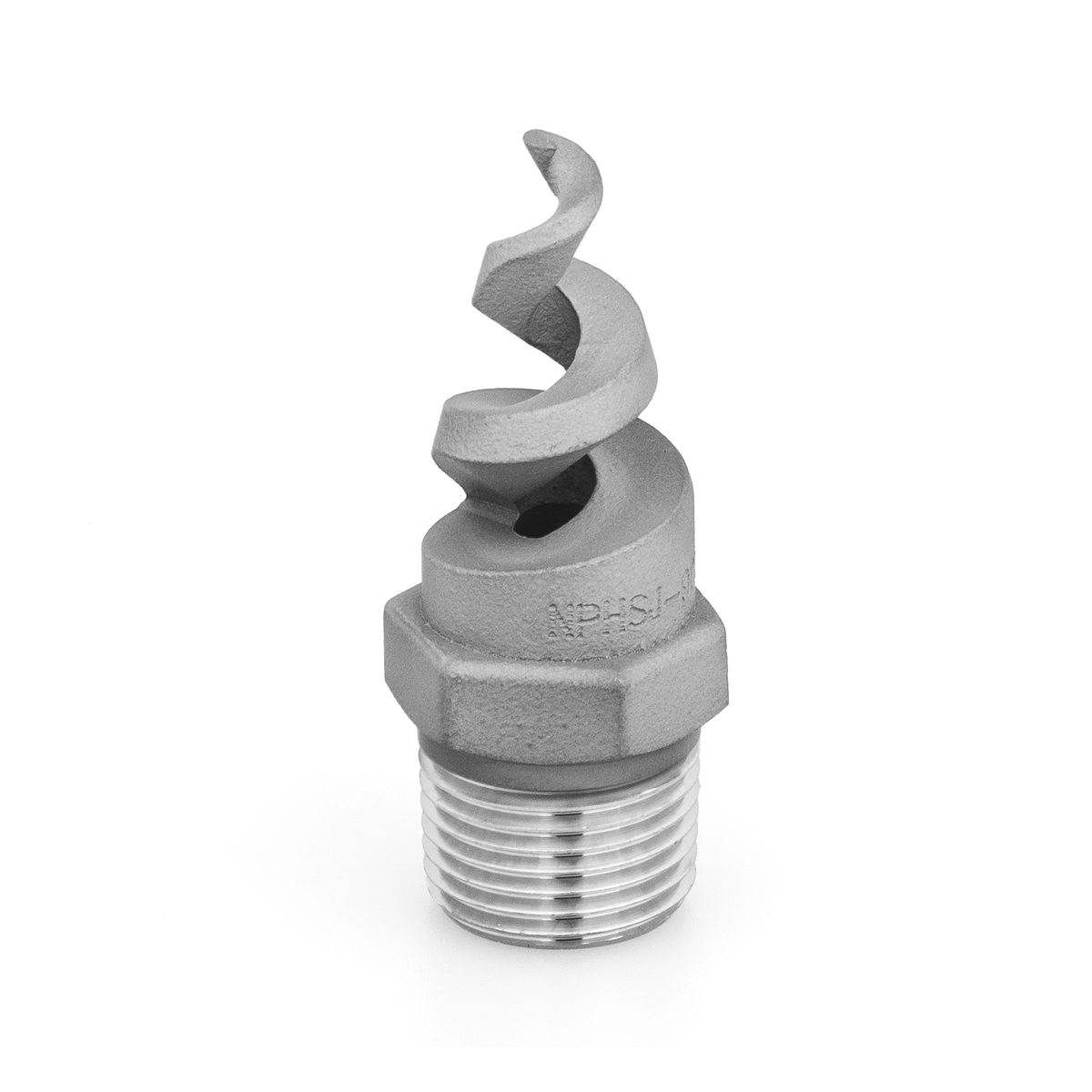

| Product Family | Full Cone Spiral |

|---|---|

| Product Series | NPHSJ |

| Capacity Size | 13 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 3.2 |

| Orifice Diameter. Nom. (in) | 0.125 |

| Inlet Connection Size (in.) | 1/4 |

| Length (mm) | 53.9 |

| Length (in) | 1.875 |

| Hex Size (mm) | 14.3 |

| Hex Size (in) | 9/16 |

| Spray Angle at Rated Pressure (PSI) | 60 |

| Max. Free Passage Dia. (mm) | 3.2 |

Description

Product Overview

During car wash on a cement site, quality managers trust the NPHSJ-6013-1/4-316 to deliver consistent and uniform spray coverage critical for removing dust and residue. Constructed from 316L stainless steel, this nozzle withstands the corrosive environment of cement dust and cleaning agents while maintaining its full cone, spiral spray pattern. Operators rely on the 1/4 inch inlet size for easy integration into existing wash systems, ensuring reliable flow rates and minimal maintenance. The result is efficient surface cleaning that supports operational uptime and reduces wear on equipment.

Applications

The nozzle's uniform spray distribution is essential for cleaning & washing processes in harsh industrial environments, helping to reduce particulate buildup and improve overall site safety. Additionally, its corrosion resistance supports applications like dust & pollution control, where sustained performance under abrasive conditions minimizes downtime.

Industries

Sectors such as building materials, cement, and mining frequently select this nozzle for its durability and consistent spray performance under demanding conditions. The chemical processing, dairy, and steel & metals industries also benefit from its corrosion-resistant properties and precise fluid delivery, which enhance process reliability and product quality.