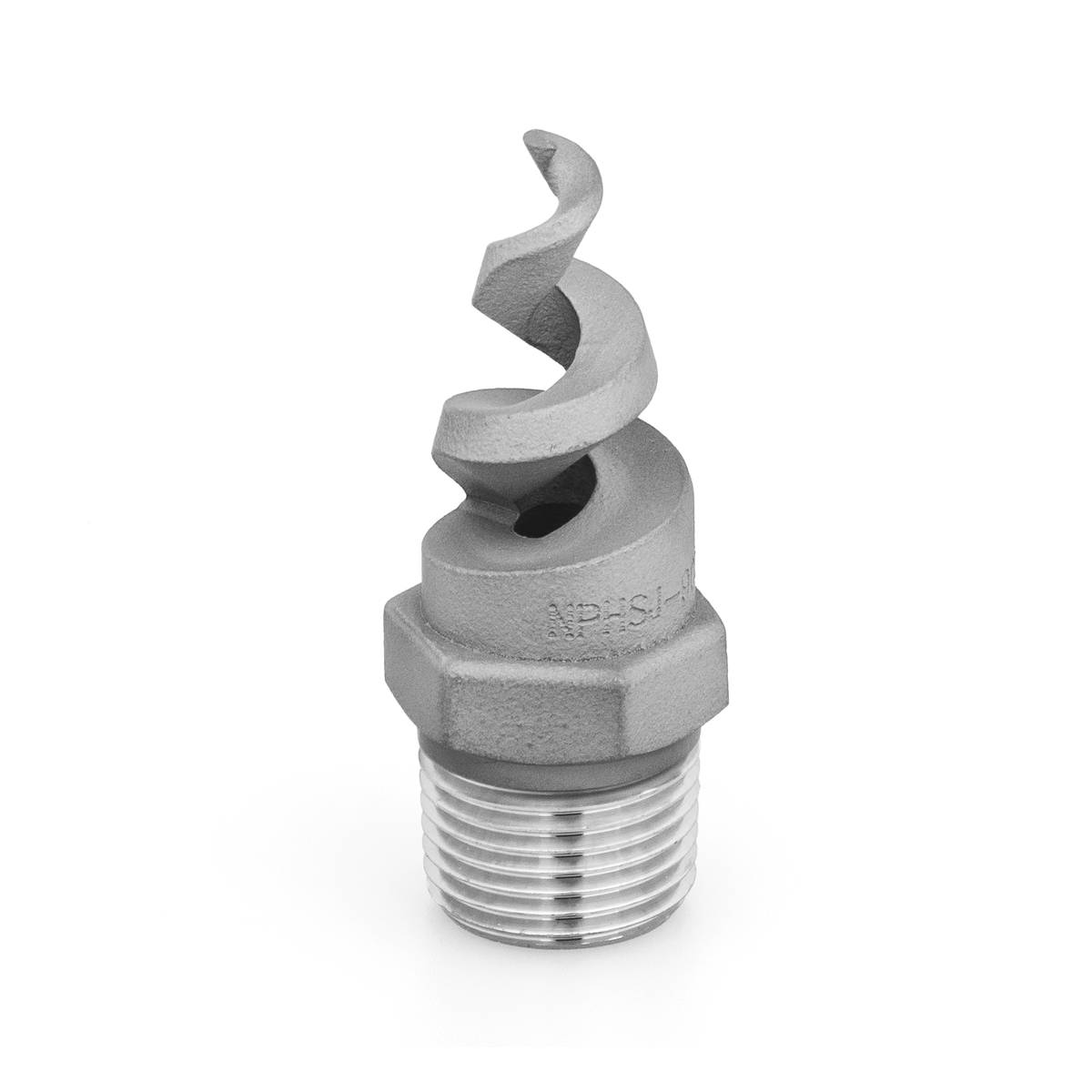

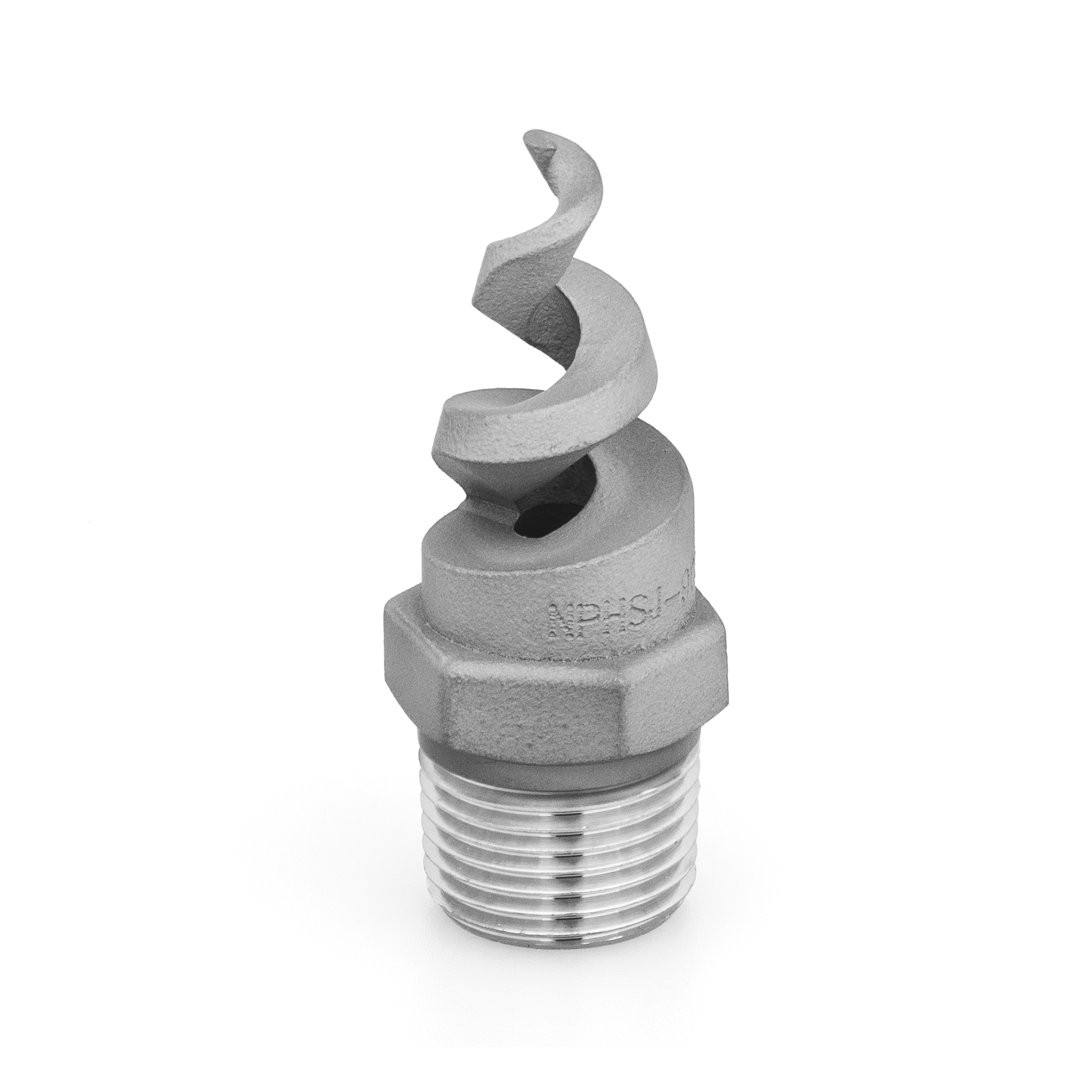

Product Parameters

| Product Family | Full Cone Spiral |

|---|---|

| Product Series | NPHSJ |

| Capacity Size | 7 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 2.4 |

| Orifice Diameter. Nom. (in) | 0.094 |

| Inlet Connection Size (in.) | 1/4 |

| Length (mm) | 53.9 |

| Length (in) | 1.875 |

| Hex Size (mm) | 14.3 |

| Hex Size (in) | 9/16 |

| Spray Angle at Rated Pressure (PSI) | 60 |

| Max. Free Passage Dia. (mm) | 2.4 |

Description

Product Overview

During cooling & quenching on a cement site, process engineers trust the NPHSJ-6007-1/4-316 to deliver consistent and effective coverage through its full cone, spiral spray pattern. Constructed from 316L stainless steel, this nozzle resists corrosion under harsh conditions, ensuring long service life and minimal maintenance. Operators install the nozzle easily using the 1/4-inch inlet, then monitor uniform spray distribution that helps maintain thermal control and reduce material stress. The combination of durable construction and predictable spray characteristics supports stable process outcomes and operational efficiency.

Applications

The nozzle's uniform spray is critical for cleaning & washing tasks, preventing buildup that can impact equipment performance and product quality. In dust & pollution control, its consistent atomization helps capture particulate matter, contributing to safer work environments and regulatory compliance.

Industries

Sectors such as building materials, chemical processing, and mining rely on this nozzle for its resistance to corrosive agents and dependable spray performance. Additionally, breweries & wineries, steel & metals, and manufacturing & assembly industries implement this component to enhance process reliability under demanding operational conditions.