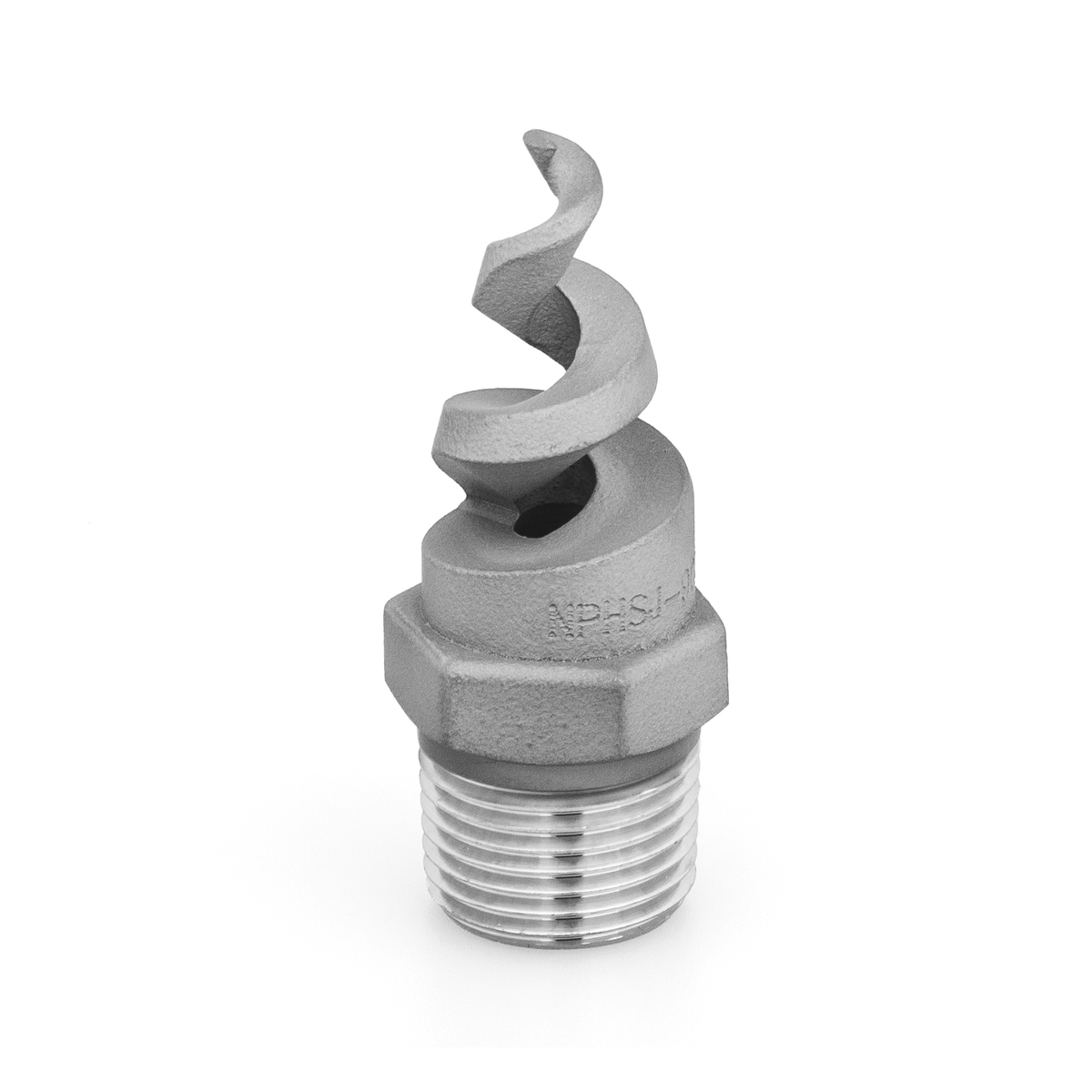

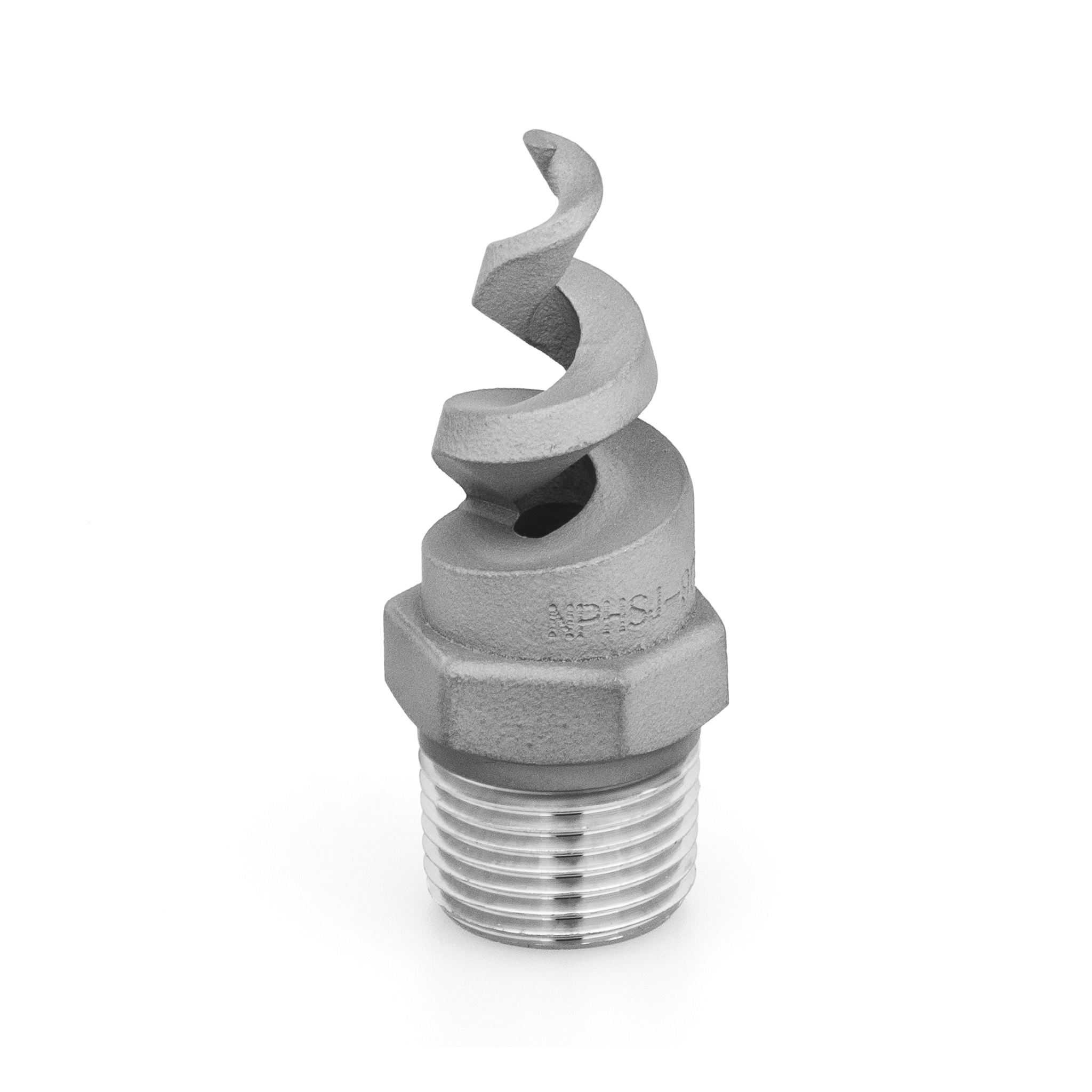

Product Parameters

| Product Family | Full Cone Spiral |

|---|---|

| Product Series | NPHSJ |

| Capacity Size | 470 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 19.1 |

| Orifice Diameter. Nom. (in) | 0.75 |

| Inlet Connection Size (in.) | 1 |

| Length (mm) | 116 |

| Length (in) | 3.625 |

| Hex Size (mm) | 34.9 |

| Hex Size (in) | 1-3/8 |

| Spray Angle at Rated Pressure (PSI) | 120 |

| Max. Free Passage Dia. (mm) | 6.4 |

Description

Product Overview

During cleaning & washing on a steel & metals site, production technicians trust the NPHSJ-120470-1-316 to deliver consistent and uniform spray coverage critical for removing residues and contaminants. Constructed from 316l stainless steel, this full cone, spiral nozzle resists corrosion in harsh environments while maintaining precise flow characteristics. The 1-inch inlet facilitates integration with existing piping systems, enabling efficient maintenance cycles. Operators rely on the nozzle's spray pattern to optimize cleaning time and reduce water consumption.

Applications

The NPHSJ-120470-1-316 excels in cleaning & washing processes where uniform spray distribution improves operational cleanliness without excessive fluid usage. Its role in cooling & quenching also supports controlling material temperatures during production, which helps prevent thermal damage and improve product quality downstream.

Industries

This nozzle is commonly chosen in building materials, chemical processing, and Energy sectors due to its corrosion resistance and durability in demanding conditions. Additionally, mining, steel & metals, and manufacturing & assembly industries benefit from its reliable spray pattern and material construction, which contribute to longer service life and consistent performance.