Product Parameters

| Product Family | Adjustable |

|---|---|

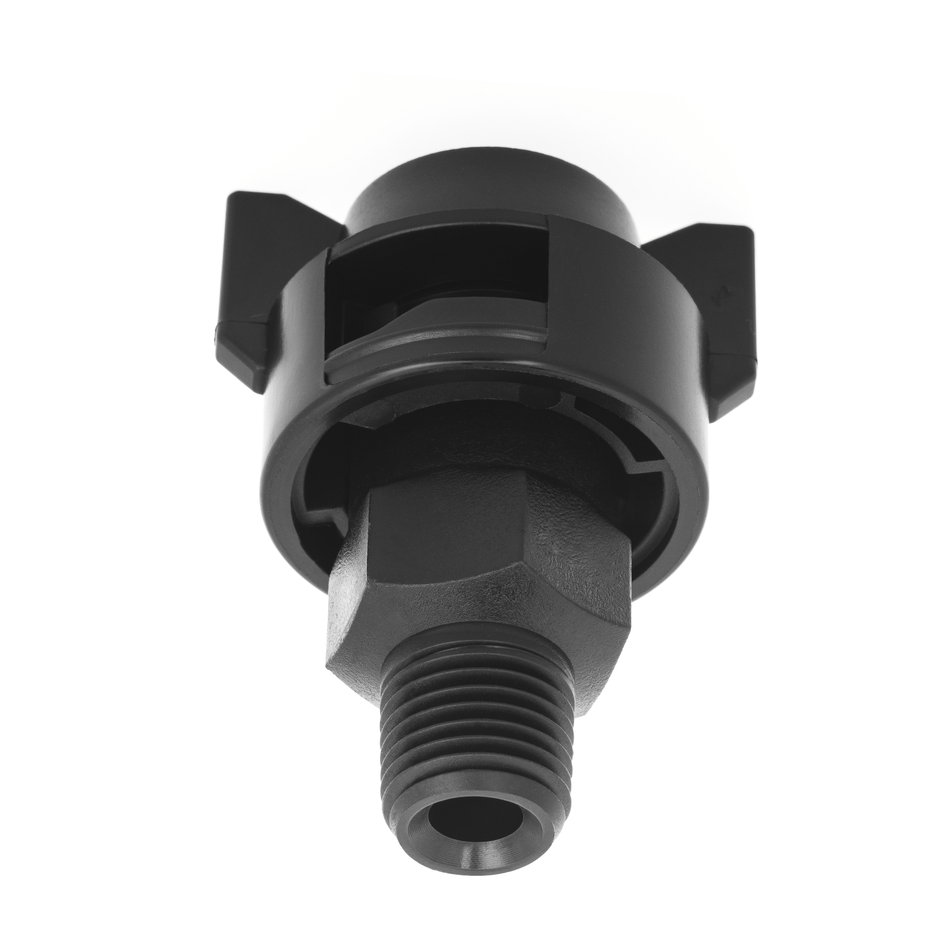

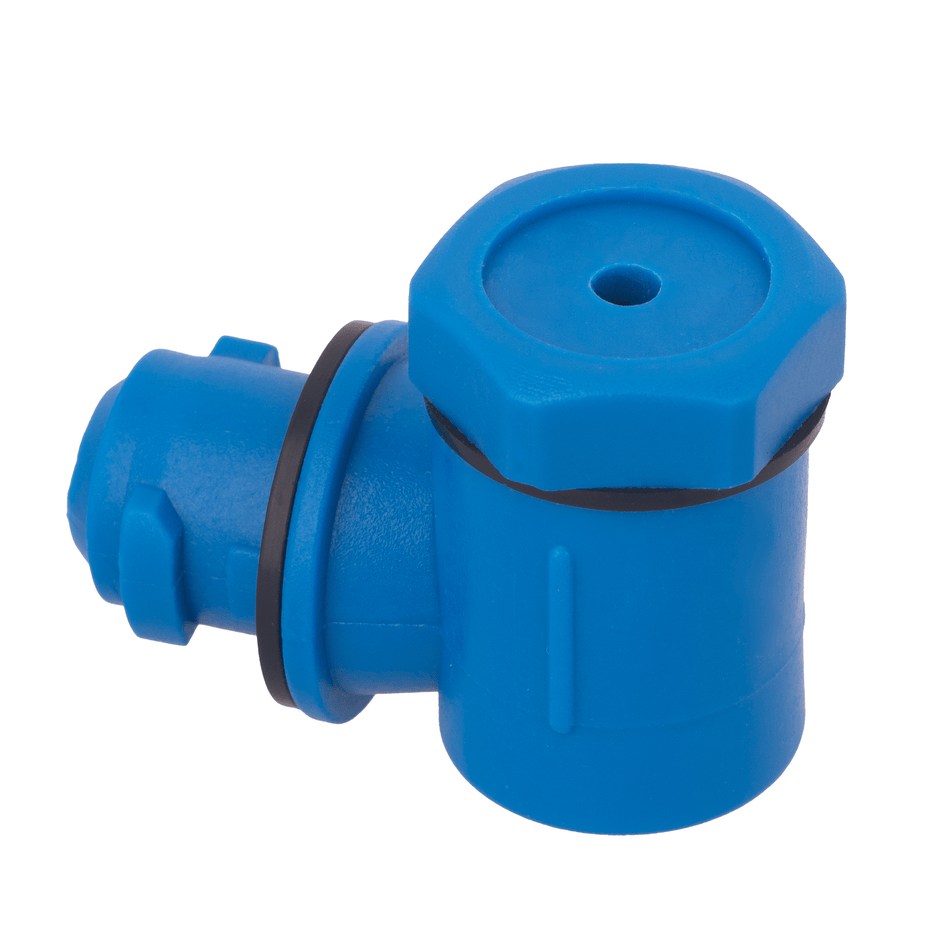

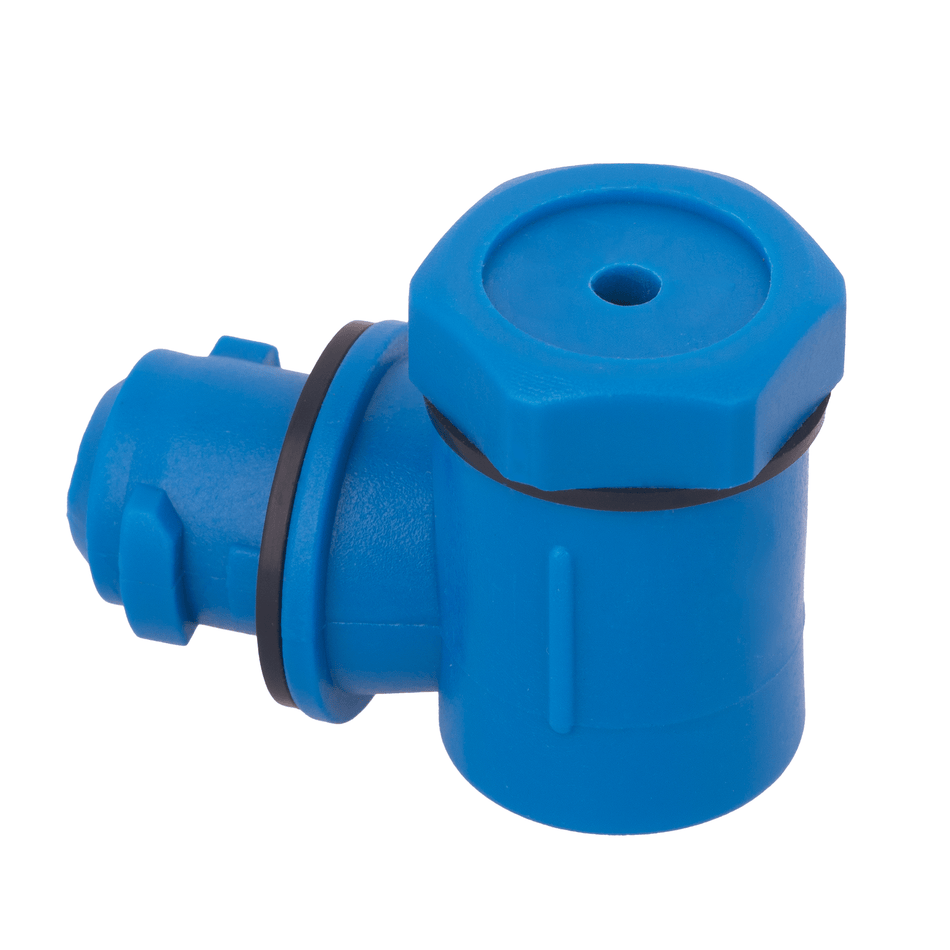

| Product Series | NPCE |

| Capacity Size | 60 |

| Material Composition Filter | Polypropylene |

| Spray Angle at Rated Pressure (PSI) | 65 |

Description

Product Overview

Inside the food & beverage line's cooling & quenching stage, a plant operator relies on the NPCE-CT6560 to deliver a consistent and adjustable spray pattern critical for maintaining product quality. Constructed from polypropylene, the nozzle resists corrosion even under continuous exposure to moisture and cleaning agents. Operators calibrate the nozzle to ensure uniform coverage, which helps control temperature precisely during the quenching process. This repeatable performance contributes to minimizing product variability and equipment wear.

Applications

In cleaning & washing operations, the NPCE-CT6560 nozzle provides stable spray distribution that enhances the removal of residues without damaging sensitive surfaces. During cooling & quenching, the nozzle's adjustability supports accurate temperature regulation, reducing cycle times and improving throughput efficiency.

Industries

Automotive, building materials, and food & beverage manufacturers favor the NPCE-CT6560 nozzle for its durability in harsh environments and its ability to maintain consistent spray characteristics. These sectors benefit from its corrosion resistance and precise flow control, which align with their stringent process requirements.