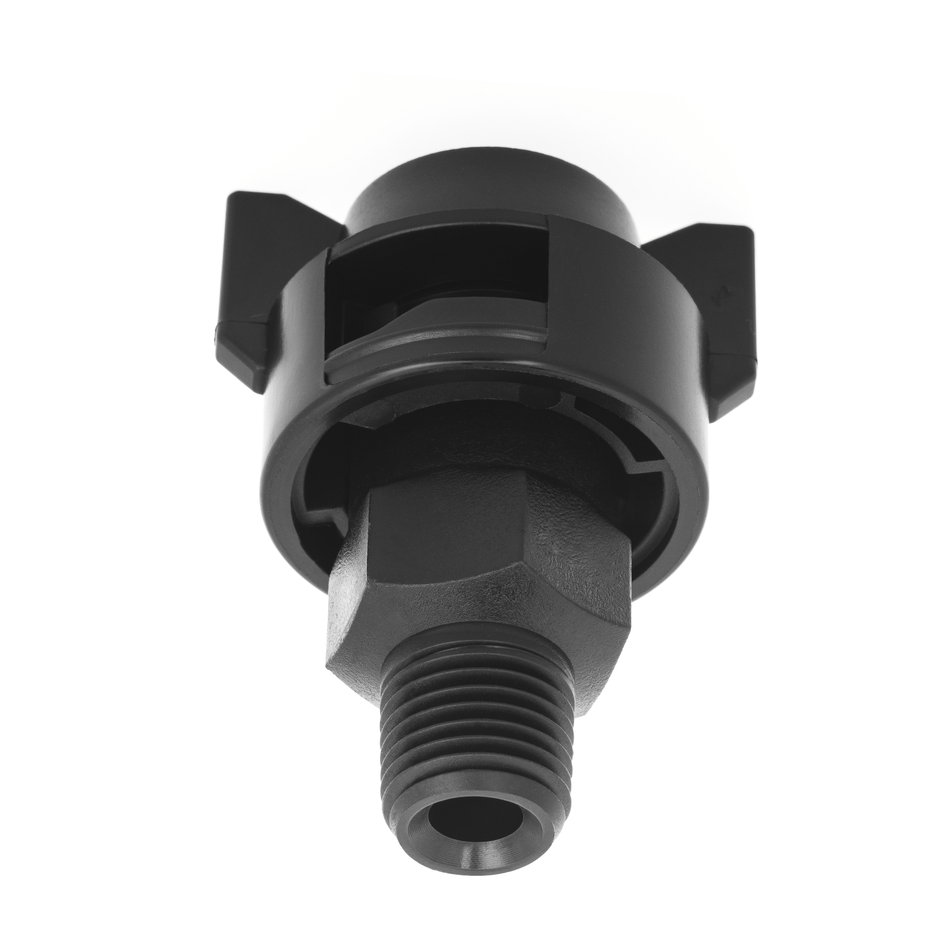

Product Parameters

| Product Family | Adjustable |

|---|---|

| Product Series | NPCE |

| Capacity Size | 60 |

| Material Composition Filter | Polypropylene |

| Orifice Diameter. Nom. (mm) | 50 |

| Spray Angle at Rated Pressure (PSI) | 50 |

Description

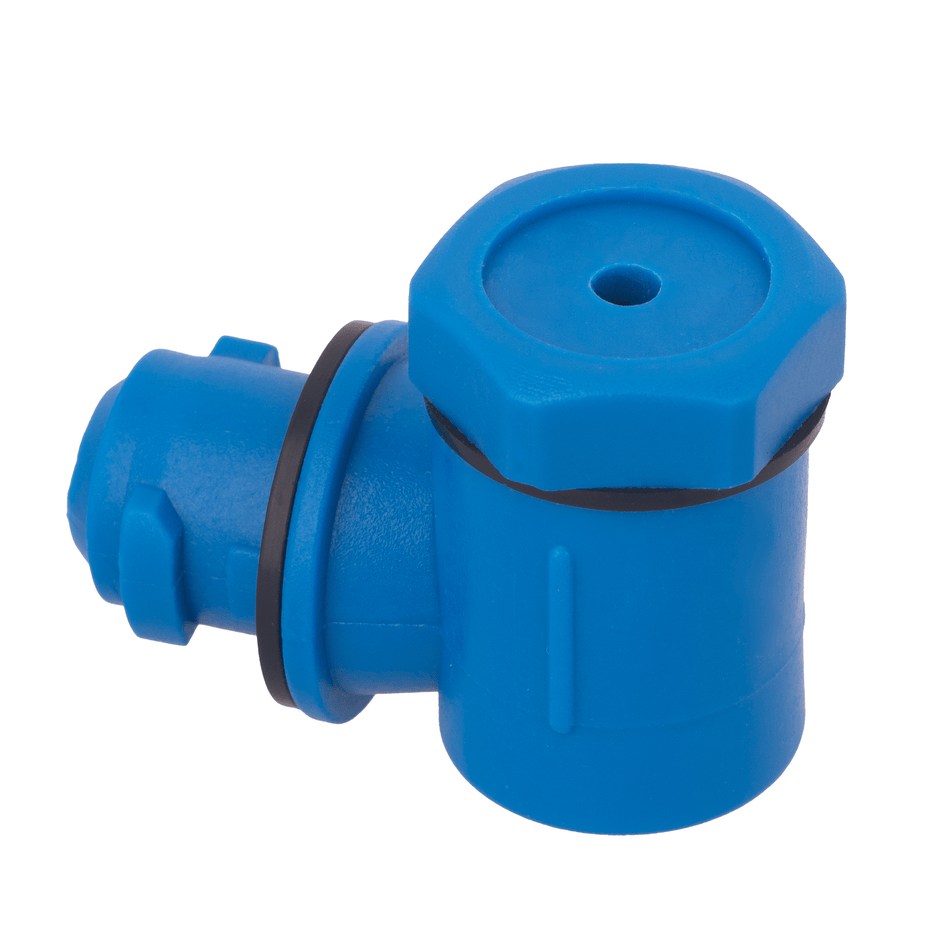

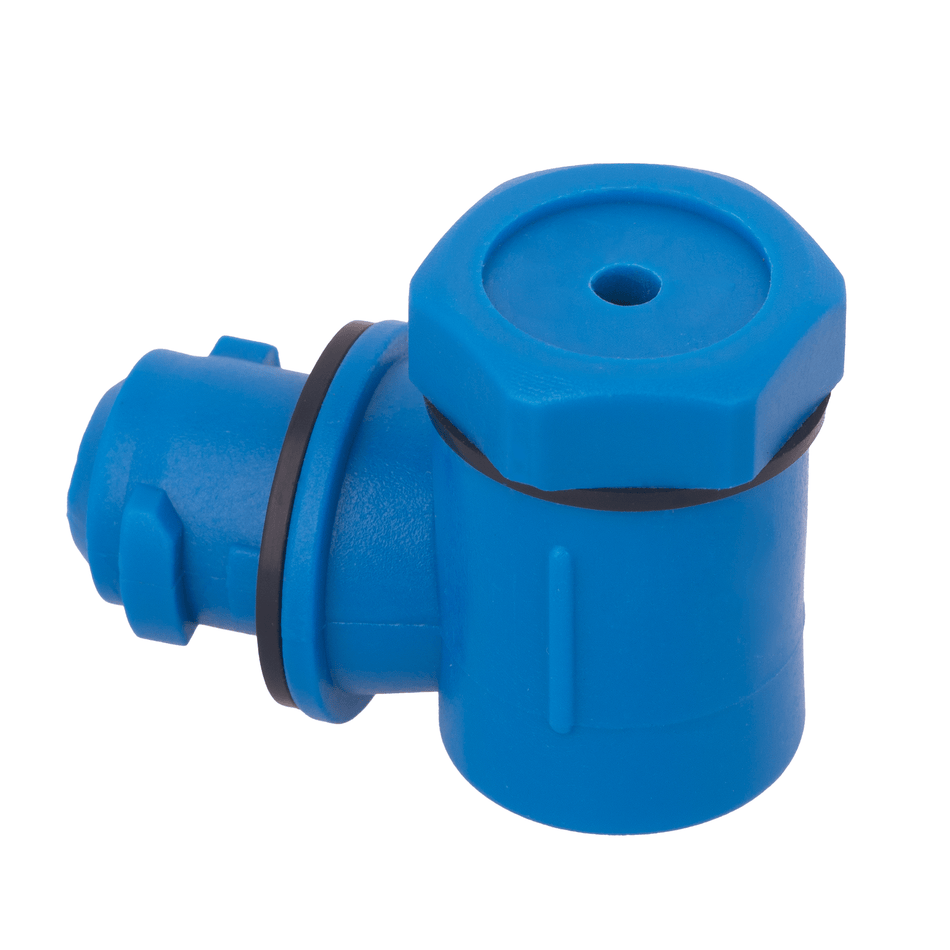

Product Overview

During cooling & quenching on an automotive site, process engineers trust the NPCE-CT5060 to deliver consistent spray coverage that is critical for material integrity. Constructed from polypropylene, this nozzle resists corrosion from chemical exposure and heat, ensuring reliable operation over extended cycles. Operators adjust the spray pattern to optimize fluid distribution, resulting in uniform cooling that reduces thermal stress and improves part quality. The precision design allows fine-tuning to meet specific process requirements with measurable improvements in efficiency.

Applications

The NPCE-CT5060 is frequently employed in cleaning & washing scenarios where uniform spray patterns help remove contaminants without damaging sensitive surfaces. In cooling & quenching applications, precise fluid delivery supports controlled temperature reduction, which minimizes distortion and enhances throughput.

Industries

Automotive, building materials, and food & beverage sectors rely on the NPCE-CT5060 for its durability and adaptability to varied process conditions. These industries require nozzles that maintain performance under continuous use, withstanding exposure to chemicals and temperature variations inherent in their workflows.