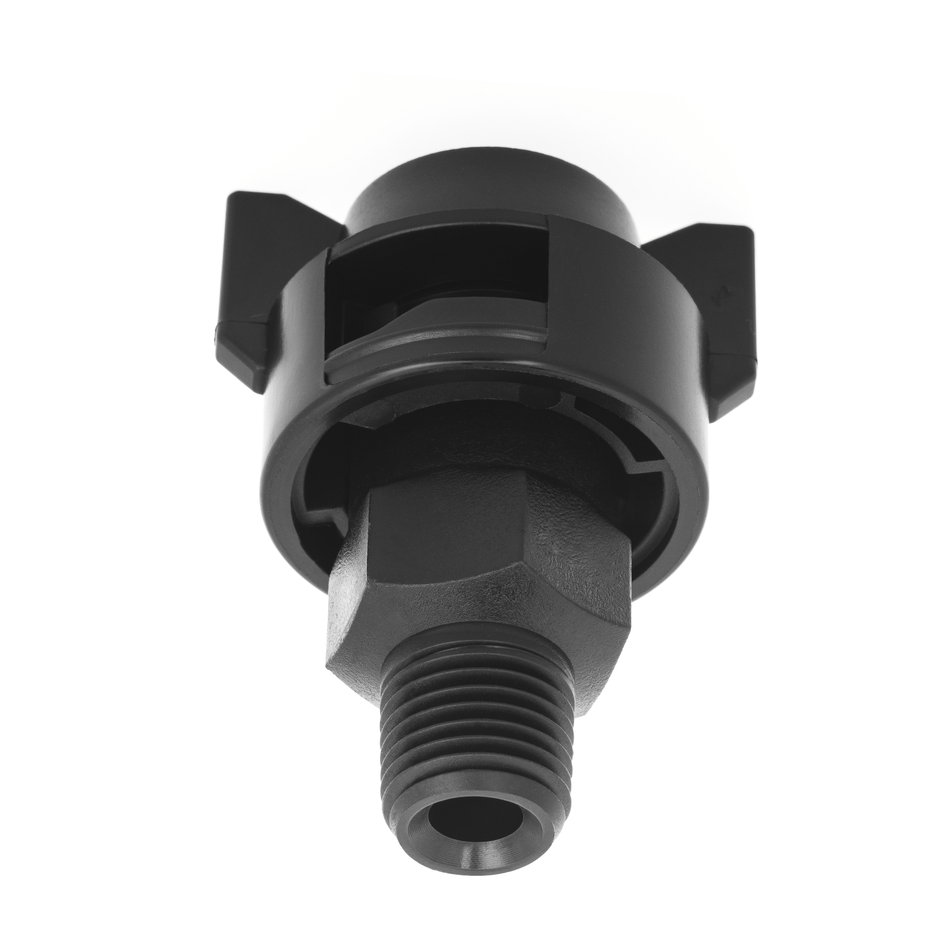

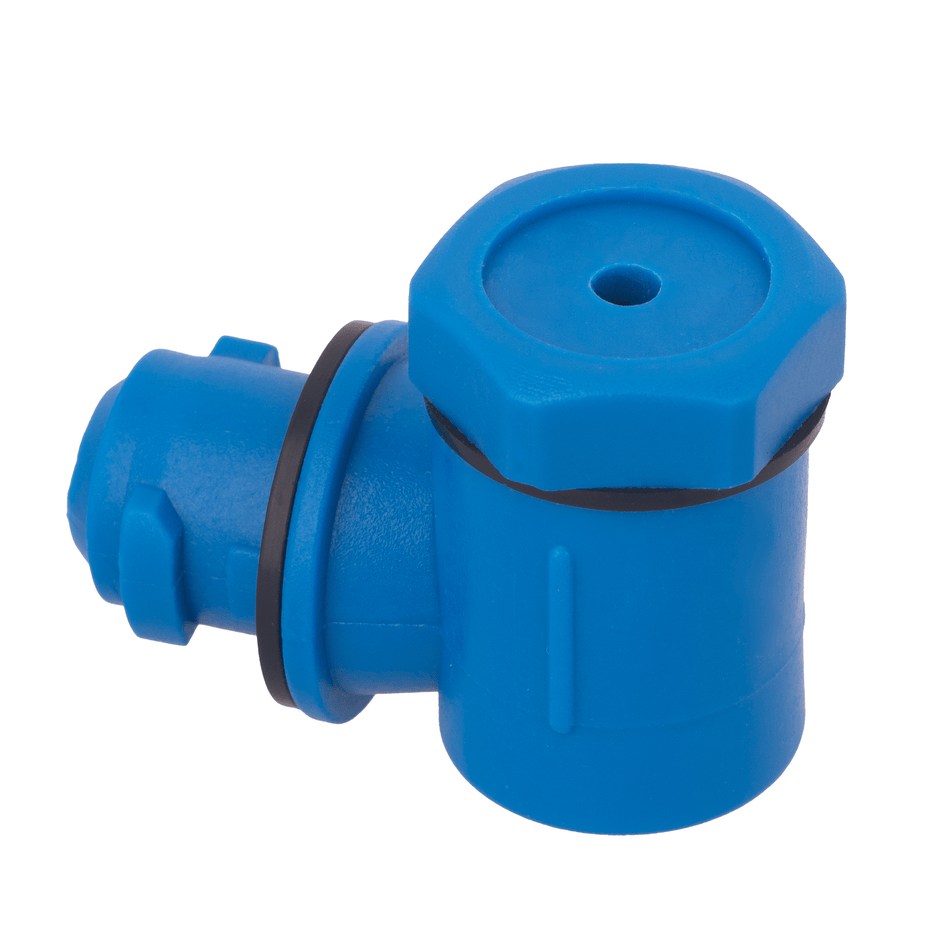

Product Parameters

| Product Family | Adjustable |

|---|---|

| Product Series | NPCE |

| Capacity Size | 20 |

| Material Composition Filter | Polypropylene |

| Orifice Diameter. Nom. (mm) | 50 |

| Spray Angle at Rated Pressure (PSI) | 50 |

Description

Product Overview

During cooling & quenching on a food & beverage site, process engineers trust the NPCE-CT5020 to deliver a consistent and adjustable spray pattern critical to maintaining product quality. Constructed from corrosion-resistant polypropylene, the nozzle withstands aggressive cleaning agents and prolonged exposure to moisture. Operators calibrate the nozzle to achieve uniform coverage, which minimizes water usage while ensuring effective cooling rates. This precision control directly influences cycle times and reduces downtime caused by uneven cooling.

Applications

The NPCE-CT5020 is frequently employed in cleaning & washing tasks where precise fluid distribution is essential to remove residues without damaging surfaces. In cooling & quenching, the nozzle's adjustable spray supports consistent temperature control that prevents thermal stress and material deformation during manufacturing.

Industries

Automotive, building materials, and food & beverage industries utilize the NPCE-CT5020 because each requires reliable fluid application under corrosive or high-moisture conditions. These sectors benefit from the nozzle's durability and adaptability to varied process demands, ensuring operational stability and quality outcomes.