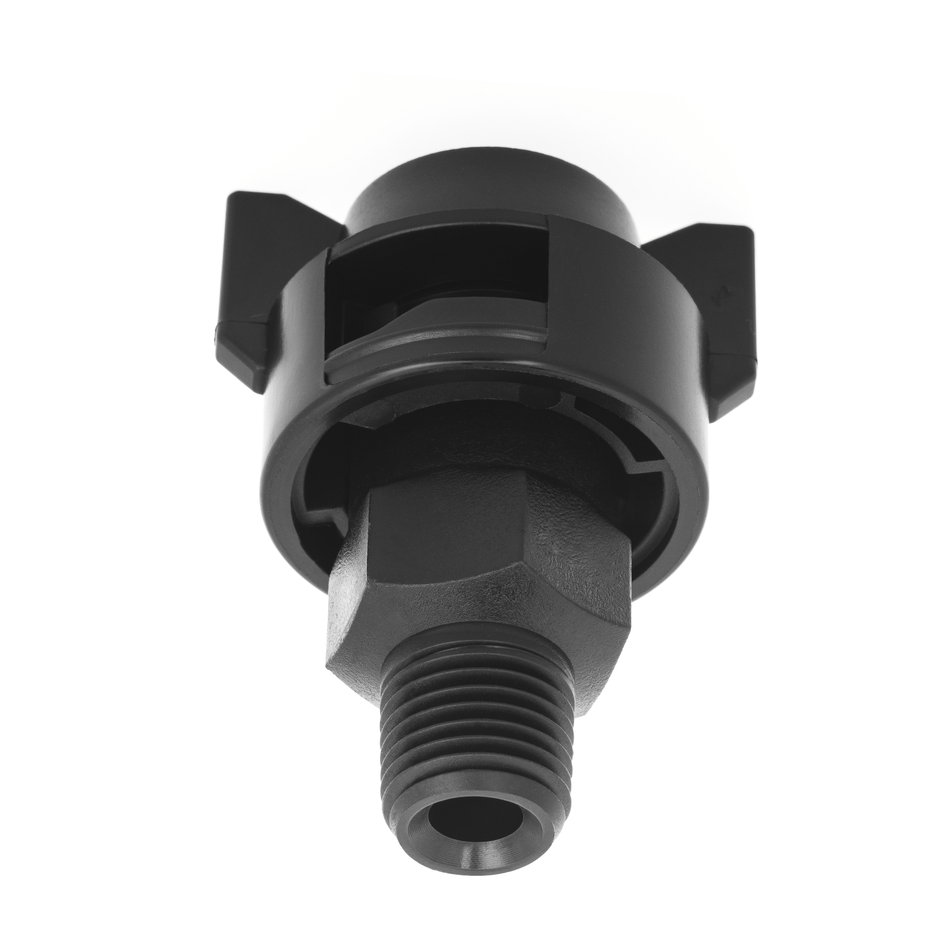

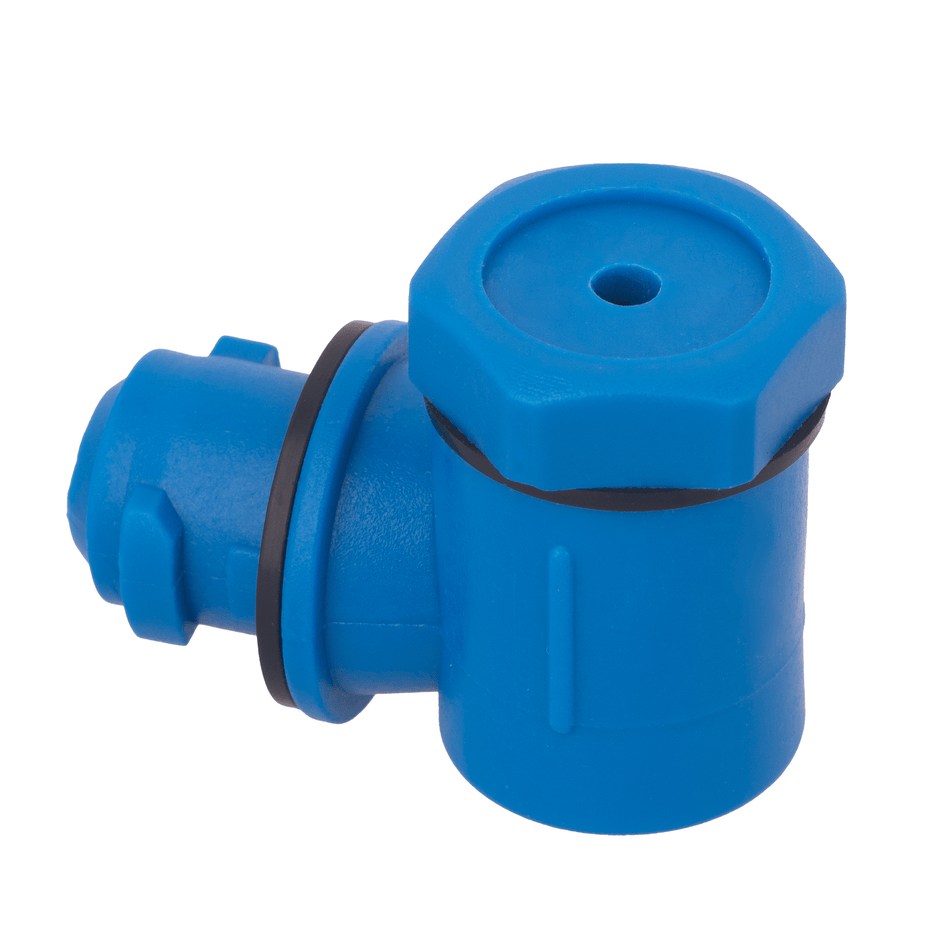

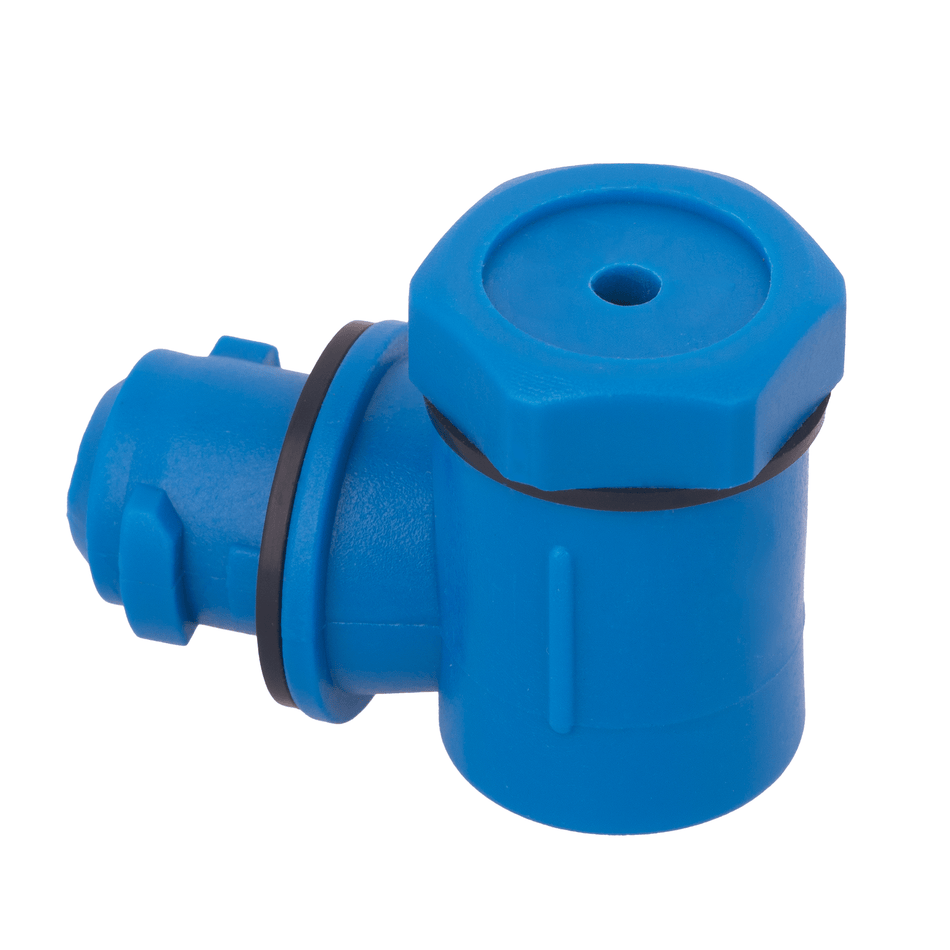

Product Parameters

| Product Family | Adjustable |

|---|---|

| Product Series | NPCE |

| Capacity Size | 50 |

| Material Composition Filter | Polypropylene |

| Orifice Diameter. Nom. (mm) | 40 |

| Spray Angle at Rated Pressure (PSI) | 40 |

Description

Product Overview

A plant operator in the food & beverage facility uses the NPCE-CT4050 during cooling & quenching to achieve consistent spray distribution across product surfaces. Constructed from polypropylene, the nozzle's corrosion-resistant design ensures durability in chemically aggressive environments. The operator adjusts the nozzle to optimize flow rate and spray angle, resulting in uniform cooling that helps maintain product quality and process efficiency. This precise control reduces material waste and minimizes downtime associated with uneven temperature exposure.

Applications

In cleaning & washing processes, the NPCE-CT4050 provides an even spray pattern that enhances the removal of residues and contaminants from equipment surfaces. During cooling & quenching operations, the nozzle's adjustability allows fine-tuning of spray intensity, which improves thermal management and protects sensitive materials from thermal stress.

Industries

The automotive, building materials, and food & beverage industries commonly select the NPCE-CT4050 for its balance of chemical resistance and spray precision. These sectors rely on consistent nozzle performance to meet stringent process requirements, including controlled cooling rates and effective surface treatment.