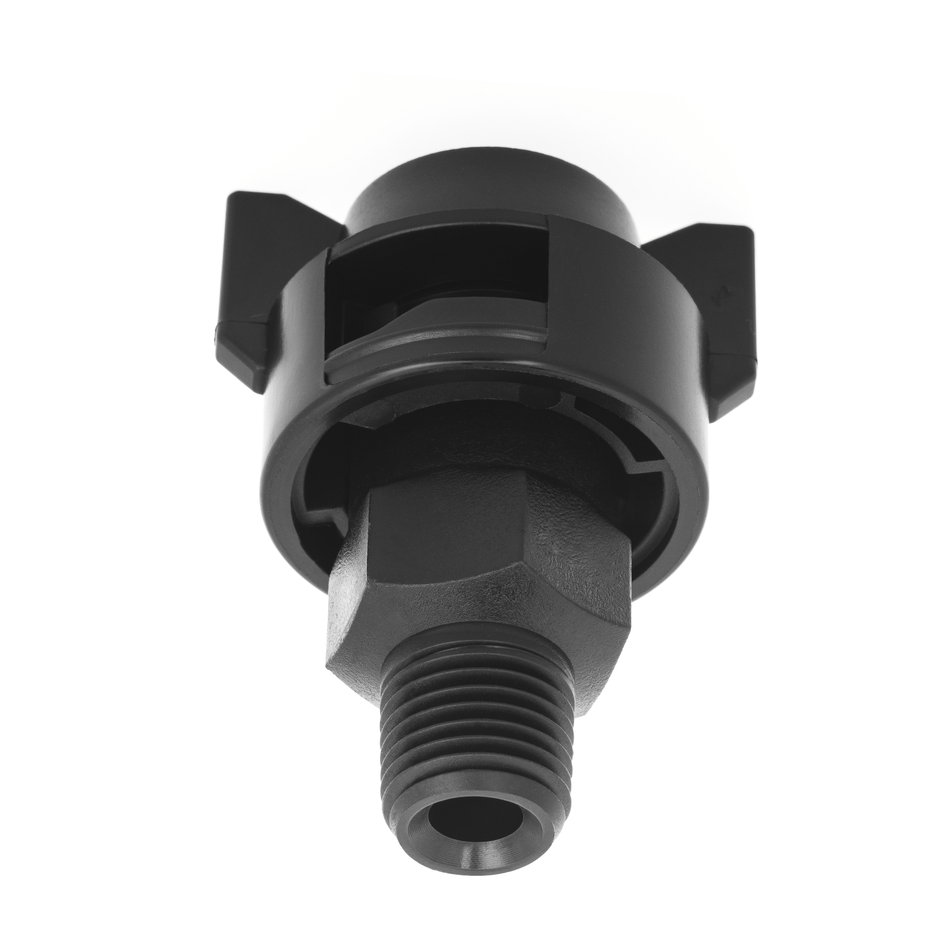

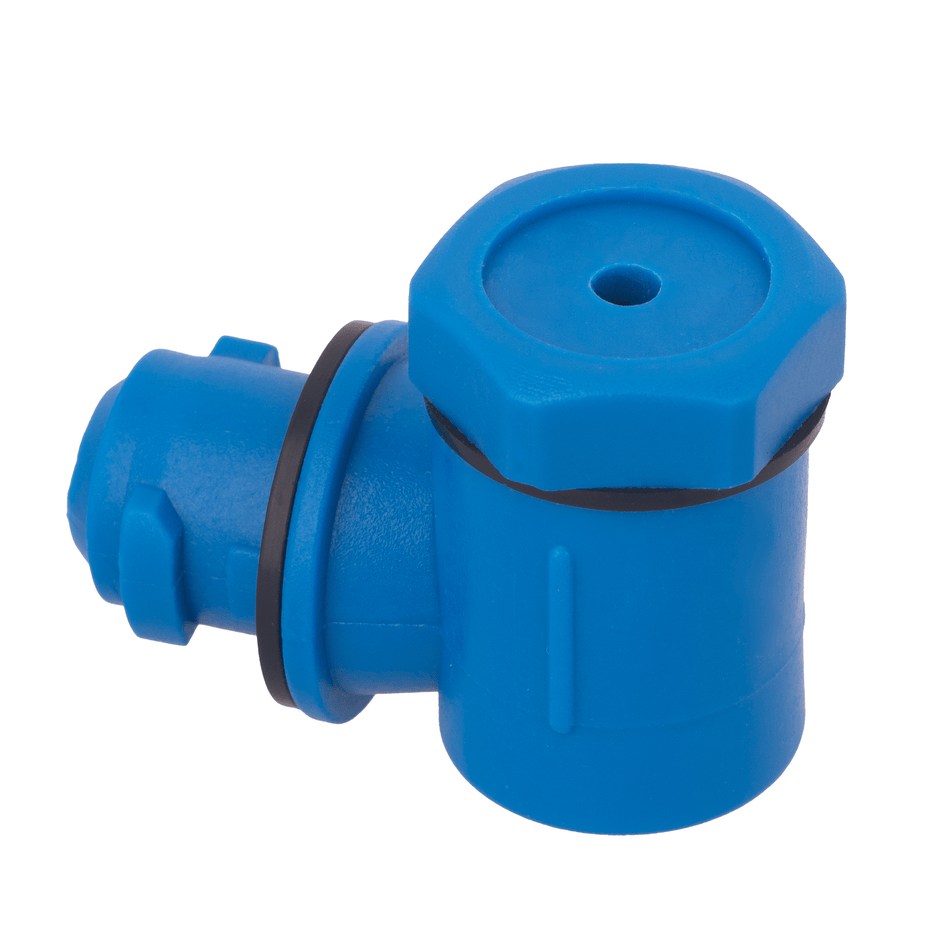

Product Parameters

| Product Family | Adjustable |

|---|---|

| Product Series | NPCE |

| Capacity Size | 60 |

| Material Composition Filter | Polypropylene |

| Orifice Diameter. Nom. (mm) | 25 |

| Spray Angle at Rated Pressure (PSI) | 25 |

Description

Product Overview

A plant operator in the food & beverage facility uses the NPCE-CT2560 during cooling & quenching to regulate the temperature of processing equipment efficiently. Constructed from polypropylene, this nozzle delivers a consistent spray pattern that maintains uniform coverage across surfaces, minimizing thermal stress. The operator adjusts the nozzle to optimize fluid flow rates, ensuring reliable corrosion resistance and extended component life. This precision adjustment capability helps maintain process stability and reduces downtime.

Applications

In cooling & quenching operations, the NPCE-CT2560 provides controlled fluid distribution that enhances heat transfer and process consistency. During cleaning & washing cycles, the nozzle's uniform spray pattern improves contaminant removal while reducing water usage and minimizing chemical exposure.

Industries

Automotive, building materials, and food & beverage sectors rely on the NPCE-CT2560 for its ability to withstand harsh environments and deliver repeatable spray performance. These industries benefit from corrosion-resistant materials and precise flow control to maintain production quality and equipment durability.