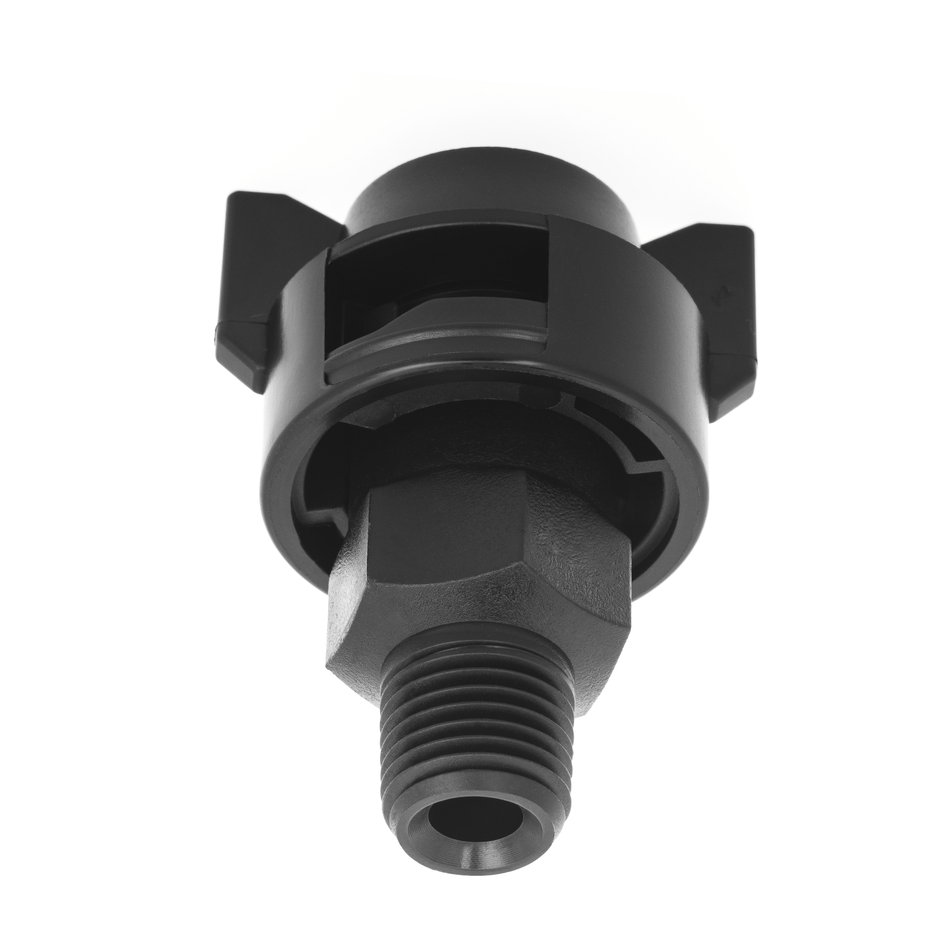

Product Parameters

| Product Family | Adjustable |

|---|---|

| Product Series | NPCE |

| Capacity Size | 15-30.1 |

| Material Composition Filter | Polypropylene |

Description

Product Overview

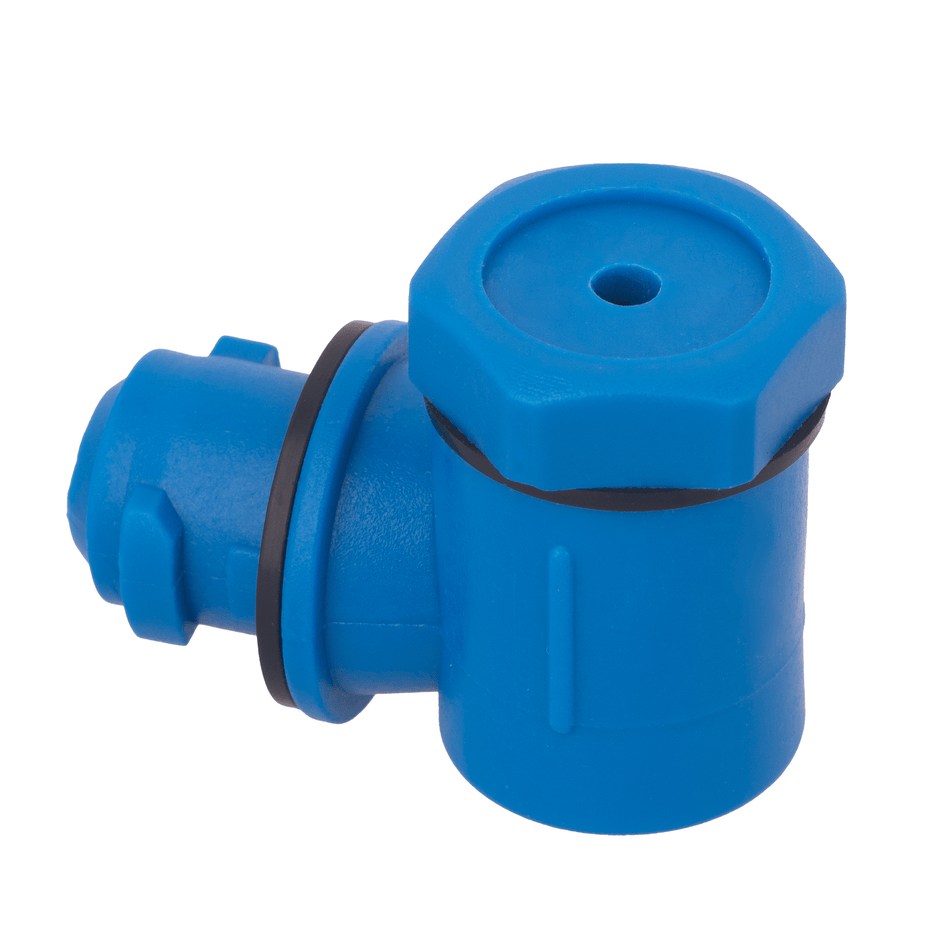

A process engineer in the automotive facility uses the NPCE-AT15-30.1 during cooling & quenching to deliver a controlled and consistent spray pattern. Made from polypropylene, the nozzle resists corrosion caused by harsh fluids and maintains performance over extended cycles. By precisely adjusting the spray angle, the engineer ensures uniform coverage across metal parts, which helps optimize temperature regulation and reduces thermal stress. This results in improved component durability and process repeatability.

Applications

In cleaning & washing operations, the NPCE-AT15-30.1 provides reliable spray distribution that effectively removes contaminants without damaging sensitive surfaces. During cooling & quenching, it supports rapid cooling rates and helps maintain product quality by delivering a consistent fluid flow tailored to specific process demands.

Industries

The automotive, building materials, and food & beverage sectors rely on the NPCE-AT15-30.1 for its durability and adaptability in environments requiring corrosion resistance and precise fluid control. These industries value its ability to maintain performance under repetitive use and exposure to various chemicals and temperatures.