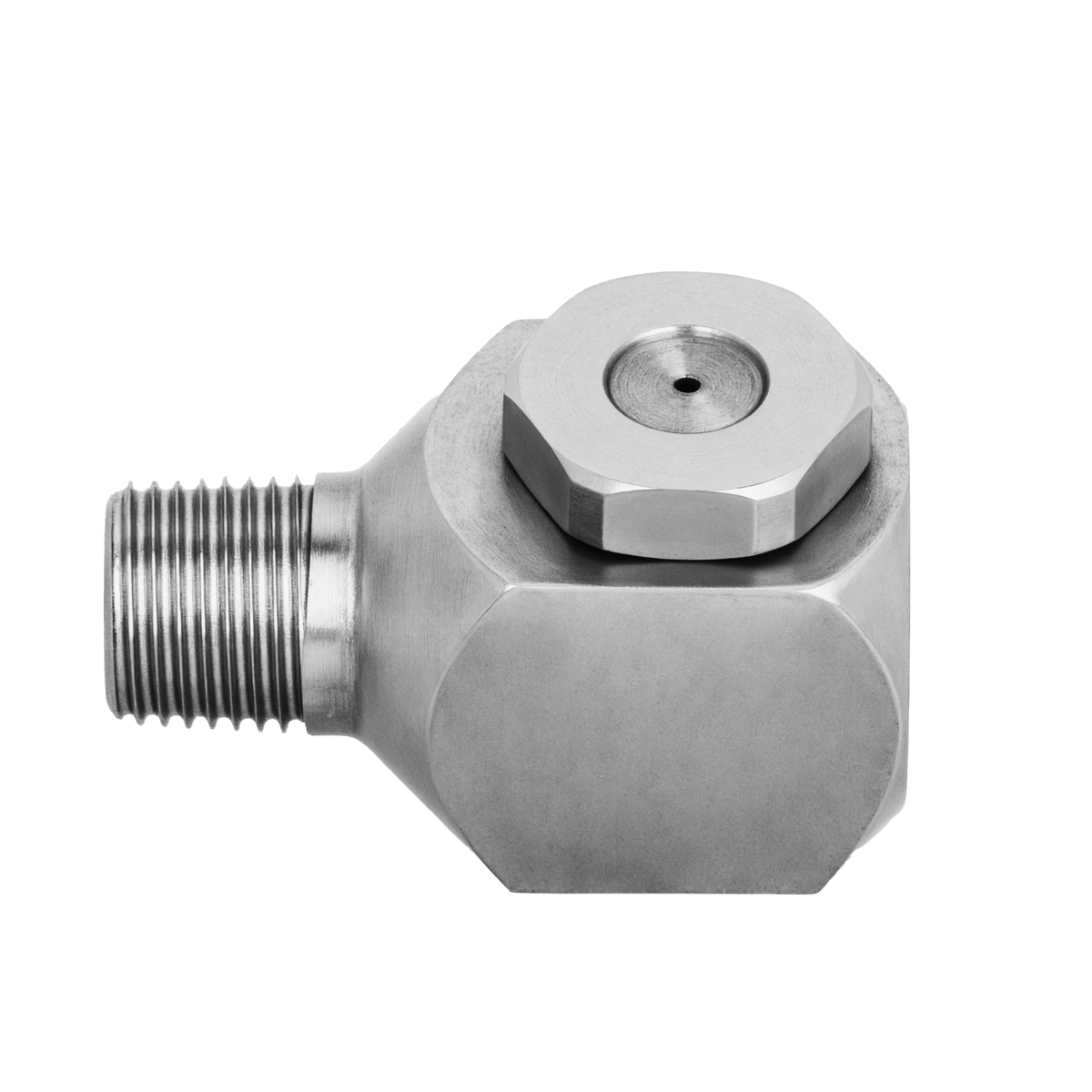

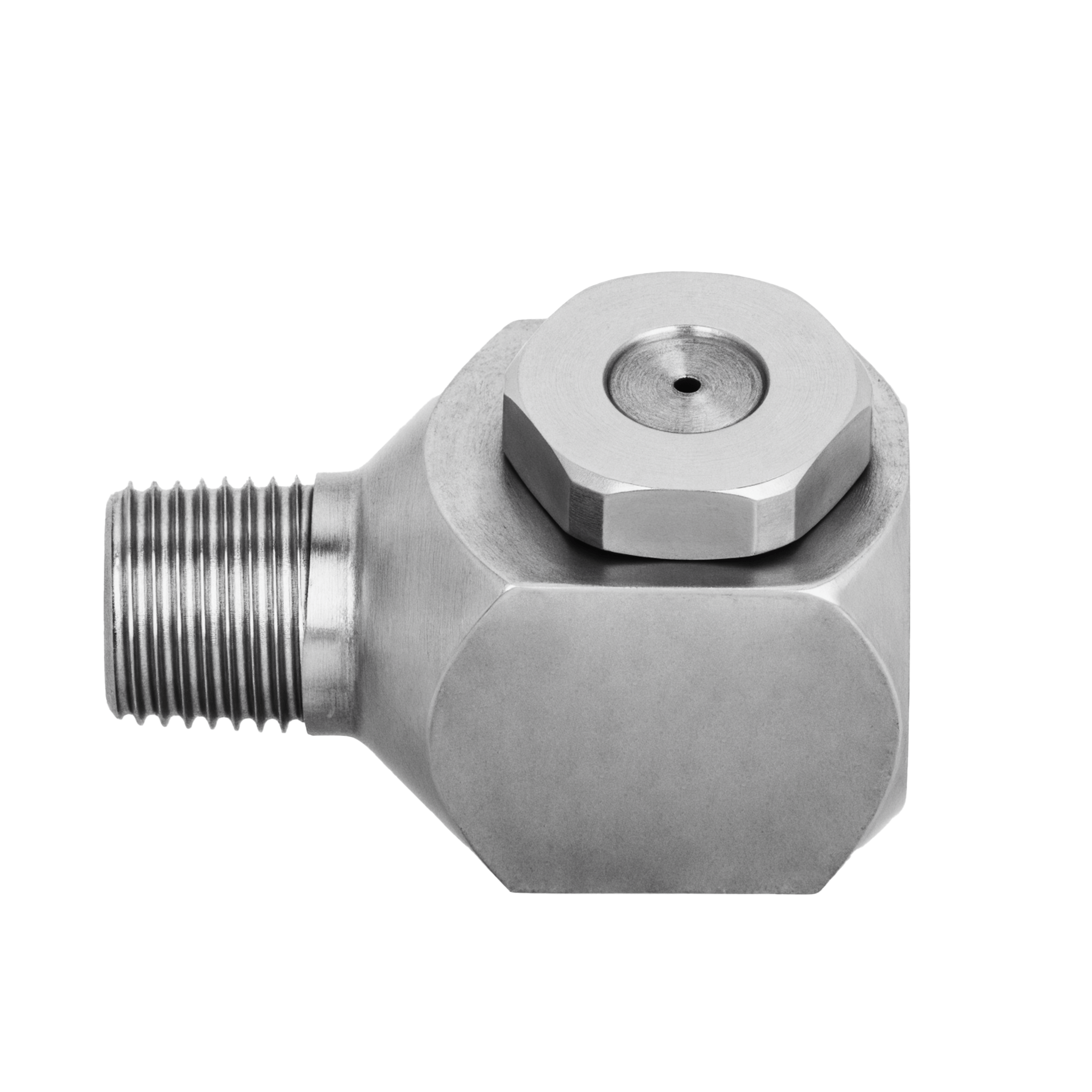

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPBX |

| Capacity Size | 8-10W |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | MALE (M) |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 4 |

| Orifice Diameter. Nom. (in) | 0.172 |

| Inlet Connection Size (in.) | 1/8 |

| Length (mm) | 30.5 |

| Length (in) | 1.188 |

| Inlet Dia. Nom. (in) | 0.156 |

| Max. Free Passage Dia. (mm) | 4.4 |

Description

Product Overview

A process engineer in the cement facility uses the NPBX-8-10W-1/8-316 during specialty applications to achieve consistent spray coverage across large conveyor belts and holding tanks. Constructed from 316L stainless steel, the nozzle withstands abrasive and corrosive environments typical in cement production. Its precision hollow cone spray pattern ensures uniform droplet distribution, which improves dust suppression and material cooling efficiency. This results in measurable reductions in particulate emissions and temperature stabilization during processing.

Applications

In dust & pollution control scenarios, the nozzle delivers a finely atomized hollow cone spray that captures airborne particulates, reducing emissions at source. Additionally, its role in humidification & conditioning helps maintain optimal moisture levels in sensitive processing areas, supporting process stability and product quality.