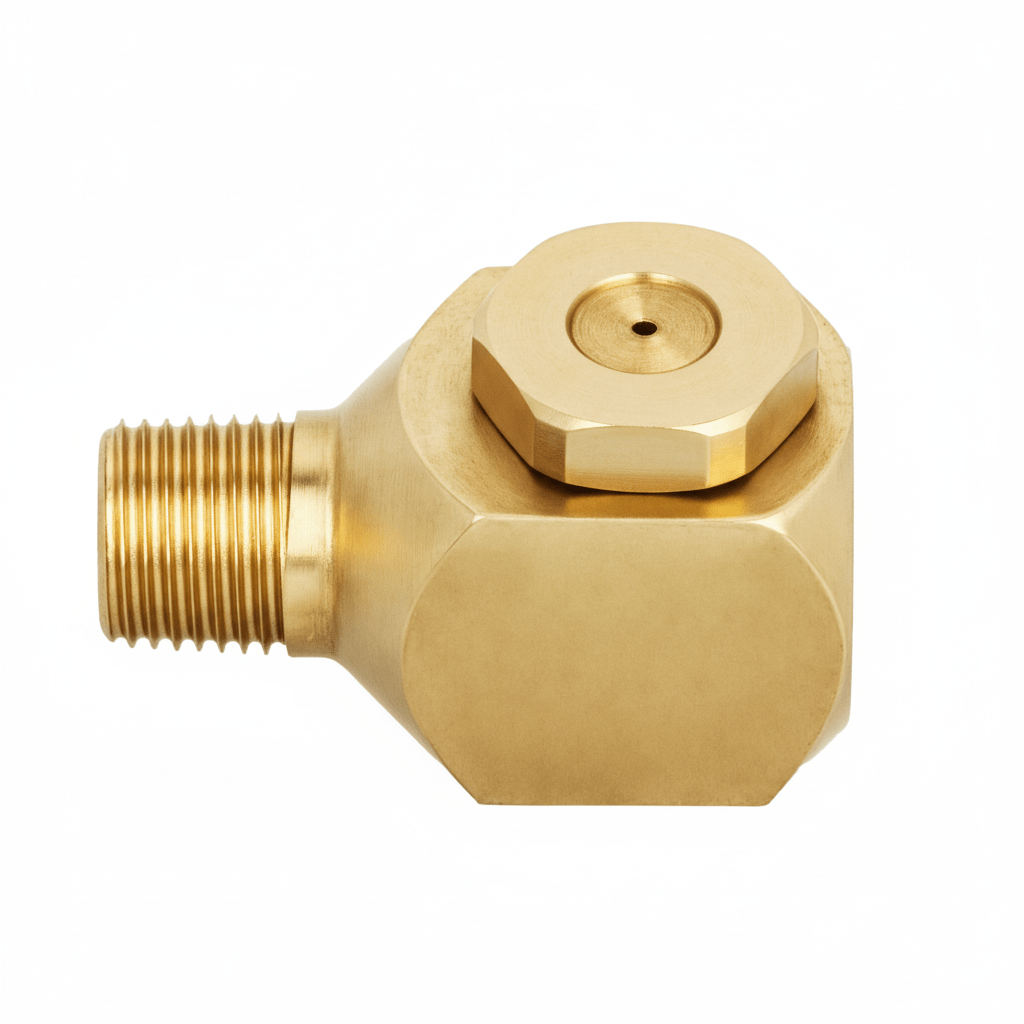

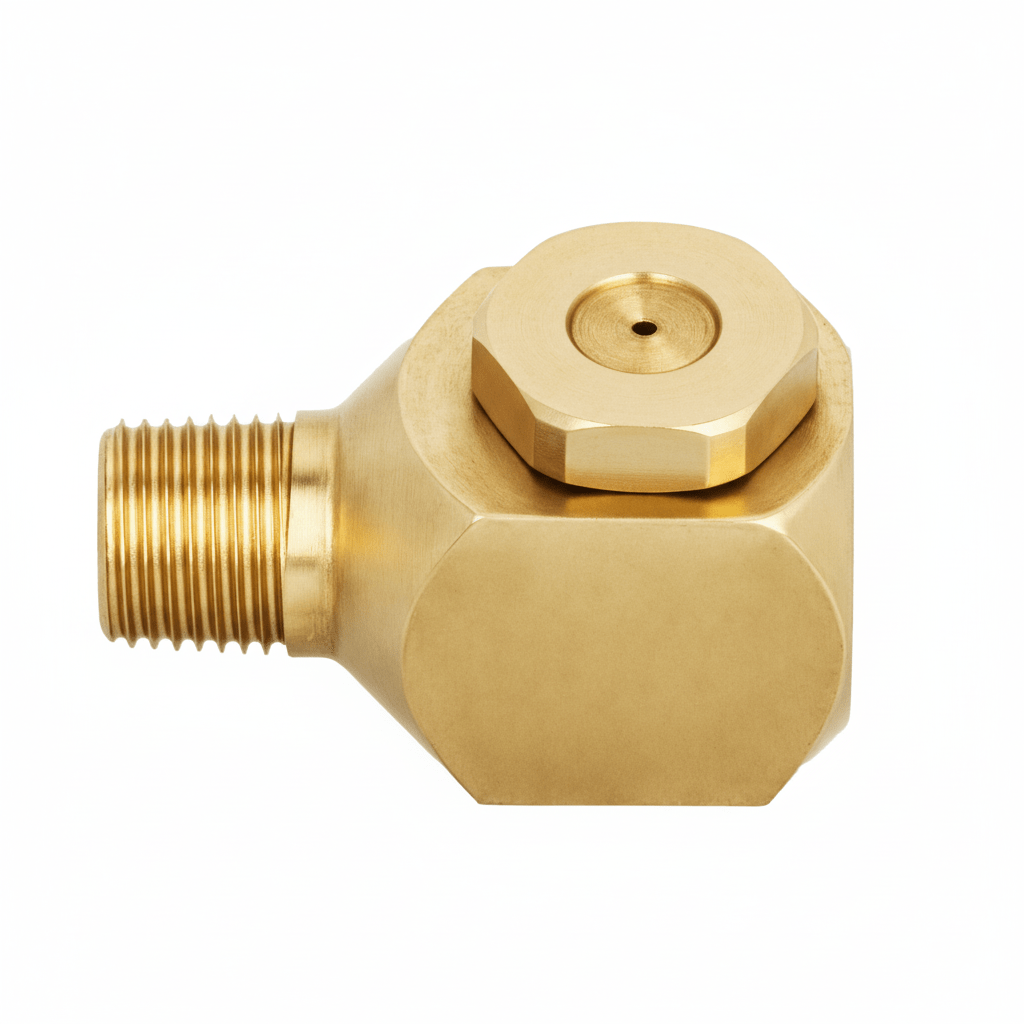

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPBX |

| Capacity Size | 50-50W |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | MALE (M) |

| Material Composition Filter | Brass |

| Orifice Diameter. Nom. (mm) | 9.5 |

| Orifice Diameter. Nom. (in) | 0.438 |

| Inlet Connection Size (in.) | 1/2 |

| Length (mm) | 49.5 |

| Length (in) | 1.938 |

| Inlet Dia. Nom. (in) | 0.375 |

| Max. Free Passage Dia. (mm) | 11.1 |

Description

Product Overview

Inside the breweries & wineries line's cooling & quenching stage, a plant operator relies on the NPBX-50-50W-1/2 to deliver consistent, uniform spray coverage essential for temperature regulation. Constructed from brass, this precision hollow cone nozzle features a 1/2 inch inlet that supports stable flow rates while resisting corrosion from frequent cleaning cycles and exposure to process fluids. By maintaining an even distribution of droplets, the nozzle helps optimize thermal transfer efficiency, reducing energy consumption and minimizing product variability. The operator integrates the NPBX-50-50W-1/2 into automated control systems to monitor spray performance and ensure repeatable process conditions.

Applications

In cooling & quenching operations, this nozzle provides reliable atomization to rapidly reduce temperatures and protect equipment integrity. It also serves a critical role in dust & pollution control by generating a fine mist that captures particulate matter, improving air quality within the facility and surrounding environment.

Industries

Automotive, building materials, and chemical processing facilities frequently select this nozzle for its corrosion resistance and uniform spray pattern, which are vital for their demanding production processes. Similarly, Energy, steel & metals, breweries & wineries, cement, manufacturing & assembly, and meat & poultry sectors benefit from its durability and consistent