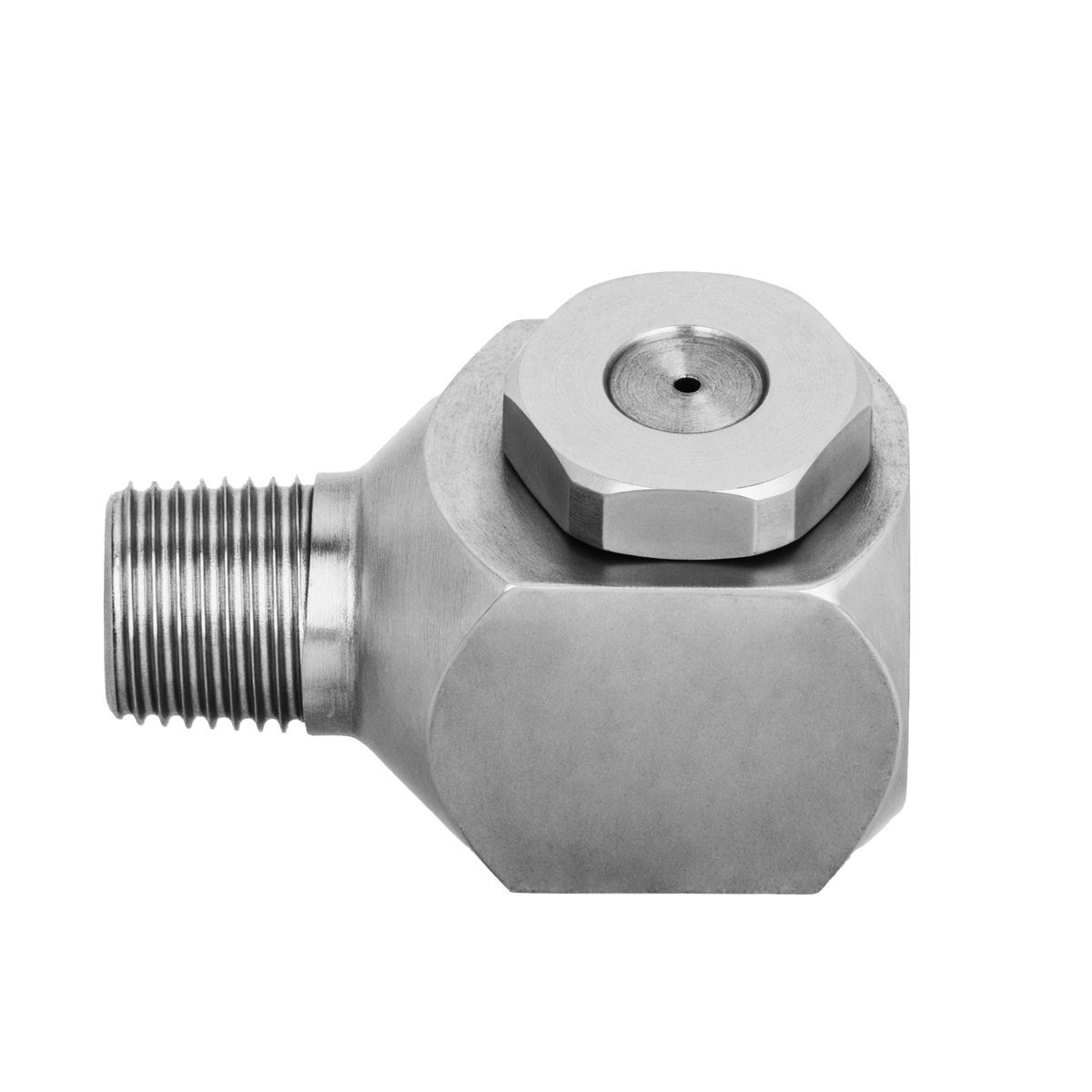

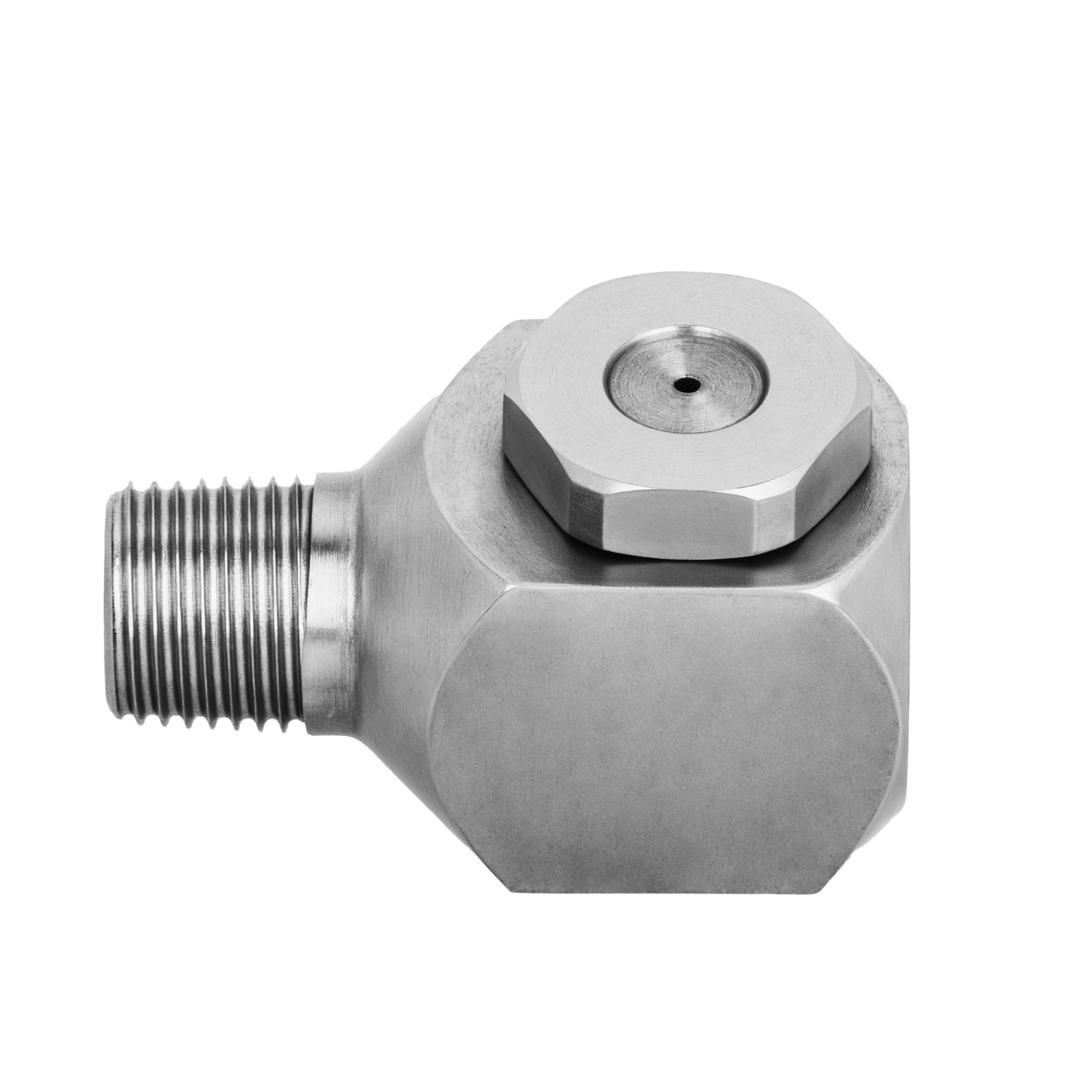

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPBX |

| Capacity Size | 25-30W |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | MALE (M) |

| Material Composition Filter | 303/304 stainless steel |

| Orifice Diameter. Nom. (mm) | 7.5 |

| Orifice Diameter. Nom. (in) | 0.313 |

| Inlet Connection Size (in.) | 3/8 |

| Length (mm) | 40 |

| Length (in) | 1.563 |

| Inlet Dia. Nom. (in) | 0.297 |

| Max. Free Passage Dia. (mm) | 7.9 |

Description

Product Overview

Inside the cement line's humidification & conditioning stage, a plant operator relies on the NPBX-25-30W-3/8-SS to maintain consistent moisture levels in raw materials. Constructed from 303/304 stainless steel, this nozzle delivers a uniform hollow cone spray pattern through its 3/8-inch inlet, ensuring even distribution across the target area. The corrosion-resistant design withstands harsh environmental conditions, reducing downtime and maintenance frequency. By achieving precise spray coverage, the operator supports stable process control and improved product quality.

Applications

This nozzle plays a critical role in humidification & conditioning by regulating moisture content to optimize material handling and prevent dust generation. Additionally, the NPBX-25-30W-3/8-SS contributes to dust & pollution control efforts, helping facilities comply with environmental standards and safeguard worker health.

Industries

Sectors such as automotive, chemical processing, and steel & metals depend on this nozzle for controlled cooling and quenching processes, while breweries & wineries, cement, and manufacturing & assembly operations utilize it to maintain consistent environmental conditions. The nozzle's material compatibility and spray characteristics make it suitable for diverse industrial environments, including meat & poultry and building materials production, where operational reliability is essential.