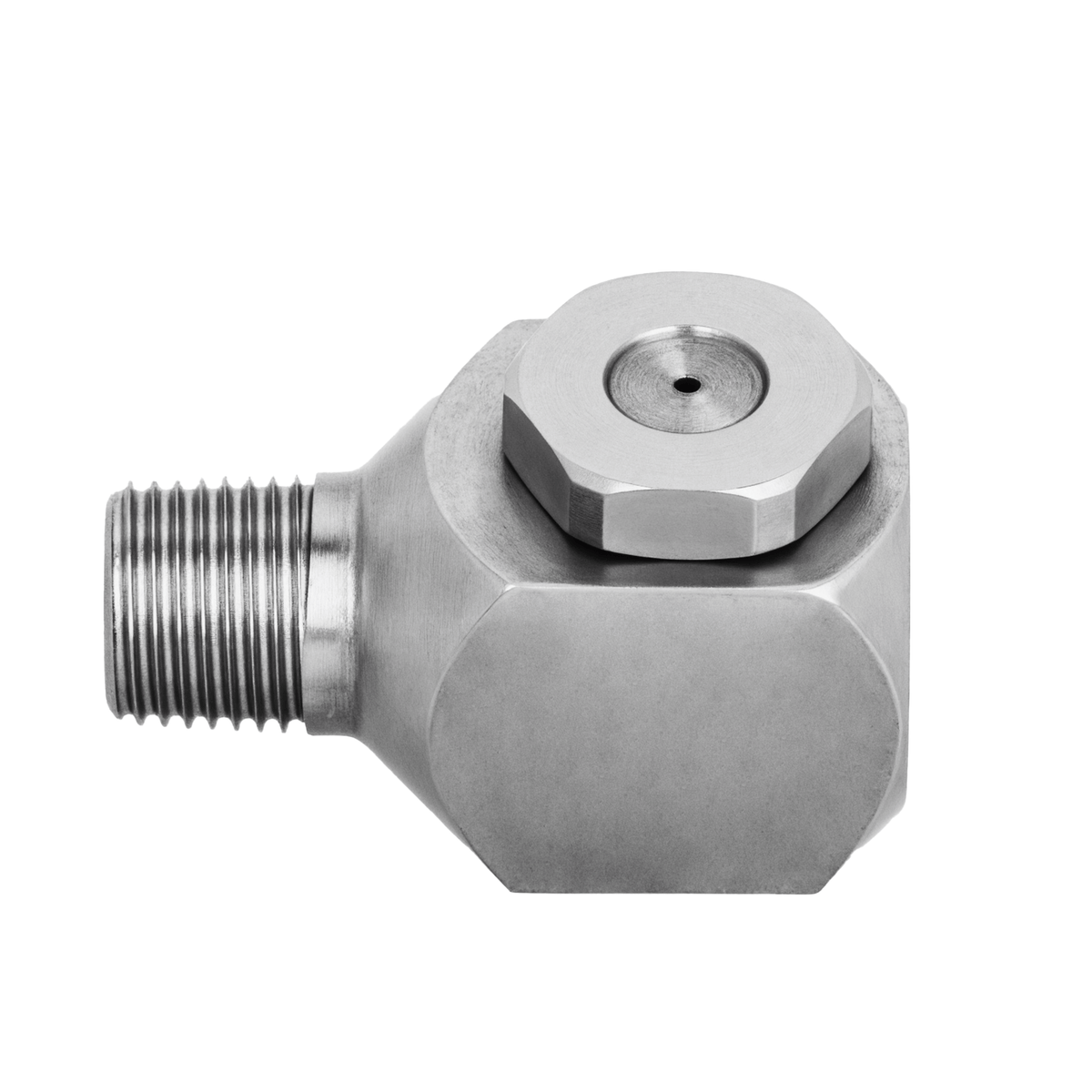

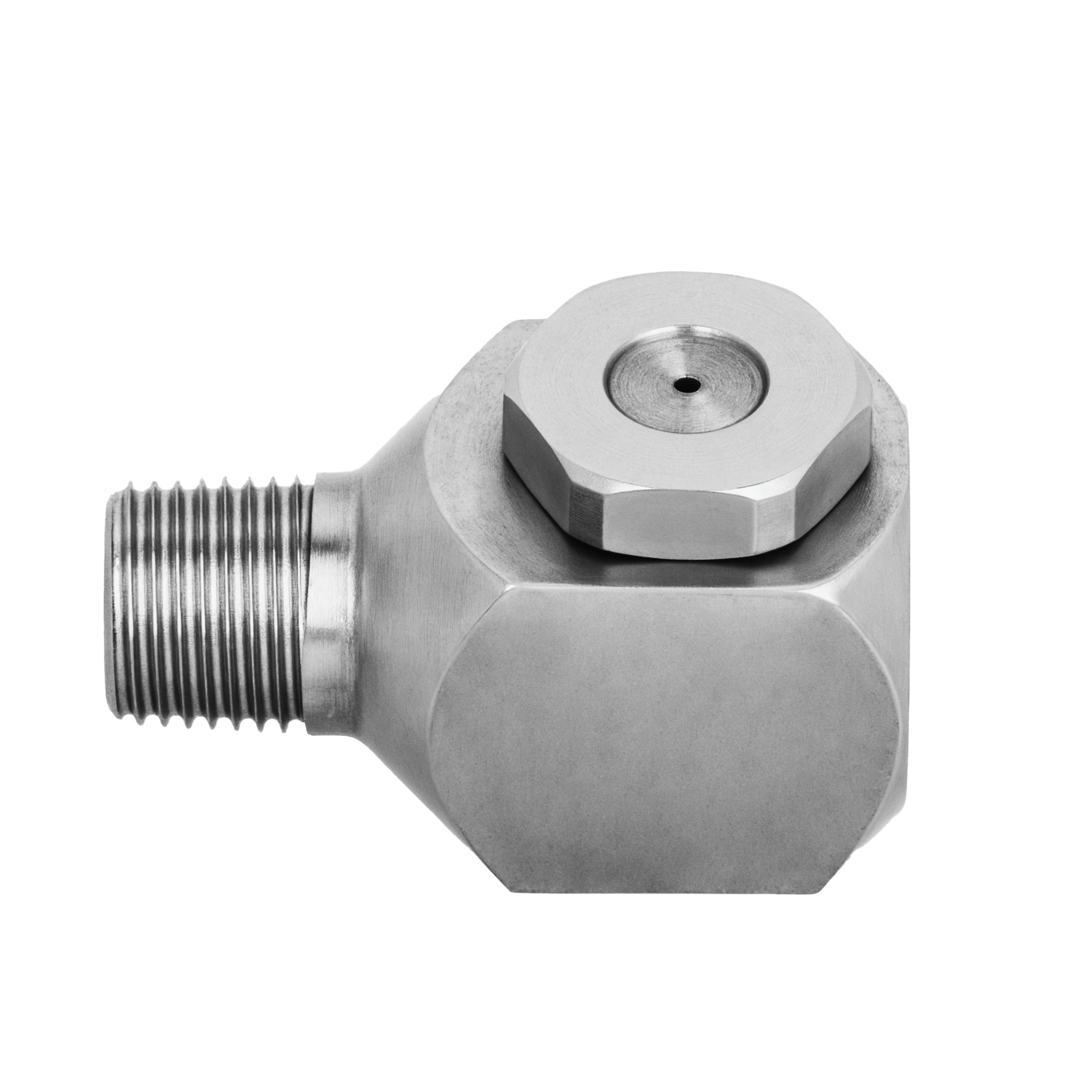

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPBX |

| Capacity Size | 25-25W |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | MALE (M) |

| Material Composition Filter | 303/304 stainless steel |

| Orifice Diameter. Nom. (mm) | 7.5 |

| Orifice Diameter. Nom. (in) | 0.297 |

| Inlet Connection Size (in.) | 3/8 |

| Length (mm) | 40 |

| Length (in) | 1.563 |

| Inlet Dia. Nom. (in) | 0.297 |

| Max. Free Passage Dia. (mm) | 7.5 |

Description

Product Overview

Inside the chemical processing line's cooling & quenching stage, a production technician relies on the NPBX-25-25W-3/8-SS to deliver a consistent spray distribution that ensures even temperature control across metal surfaces. Crafted from corrosion-resistant 303/304 stainless steel, the nozzle withstands harsh process fluids and abrasive environments without degrading. Its precision hollow cone spray pattern optimizes coverage while minimizing fluid waste, contributing to improved process stability and reduced downtime. By integrating this nozzle, operators achieve repeatable spray performance critical for maintaining product quality.

Applications

The NPBX-25-25W-3/8-SS supports cooling & quenching operations by providing a uniform hollow cone spray that rapidly dissipates heat in industrial equipment. Additionally, it plays a role in dust & pollution control by atomizing liquids to capture particulate matter, helping facilities meet environmental compliance standards.

Industries

This nozzle is favored across industries such as automotive, steel & metals, and manufacturing & assembly due to its durability and consistent spray output under demanding conditions. Facilities in chemical processing, cement, and breweries & wineries also utilize it to maintain precise liquid distribution in various process stages, benefiting from the material's resistance to corrosion and wear.