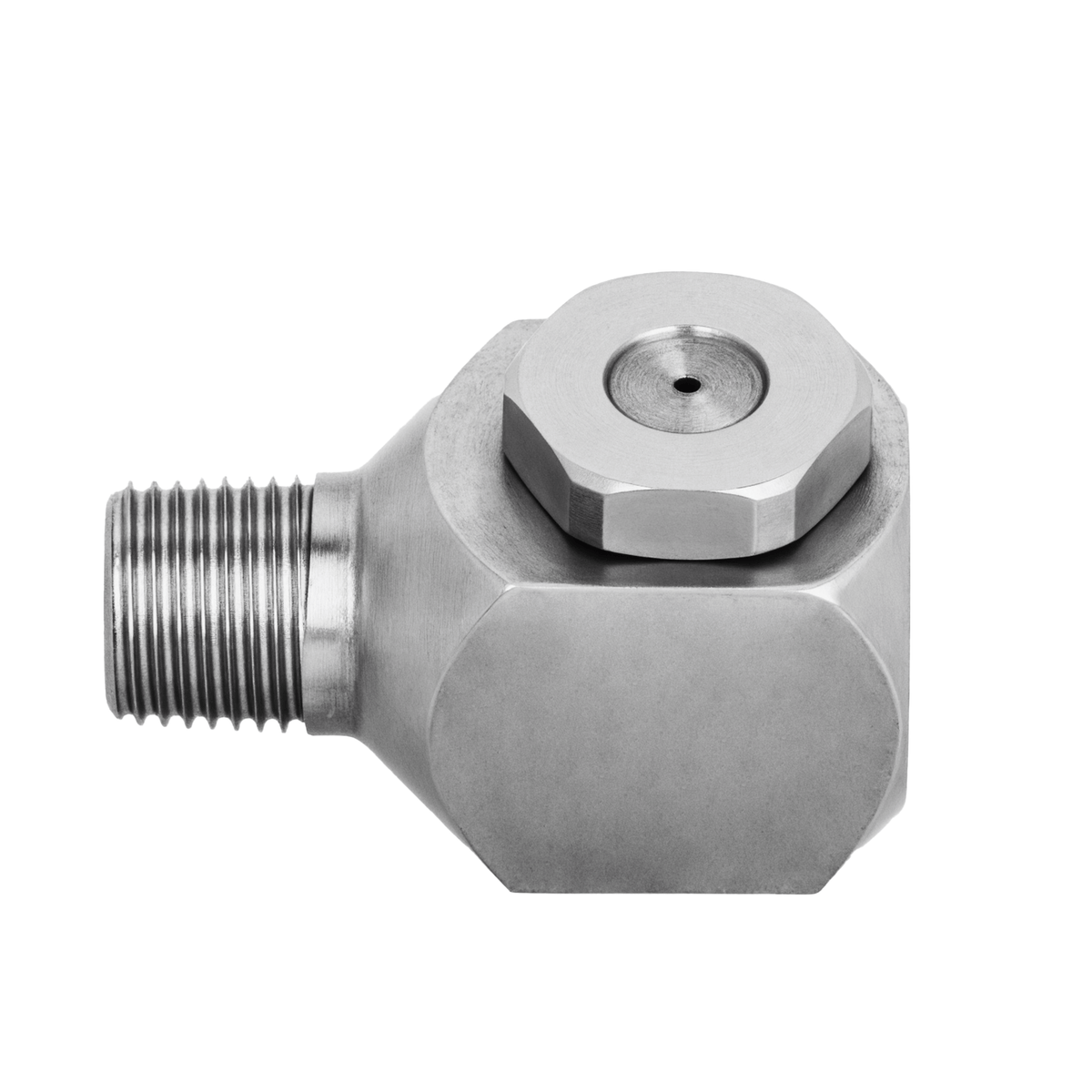

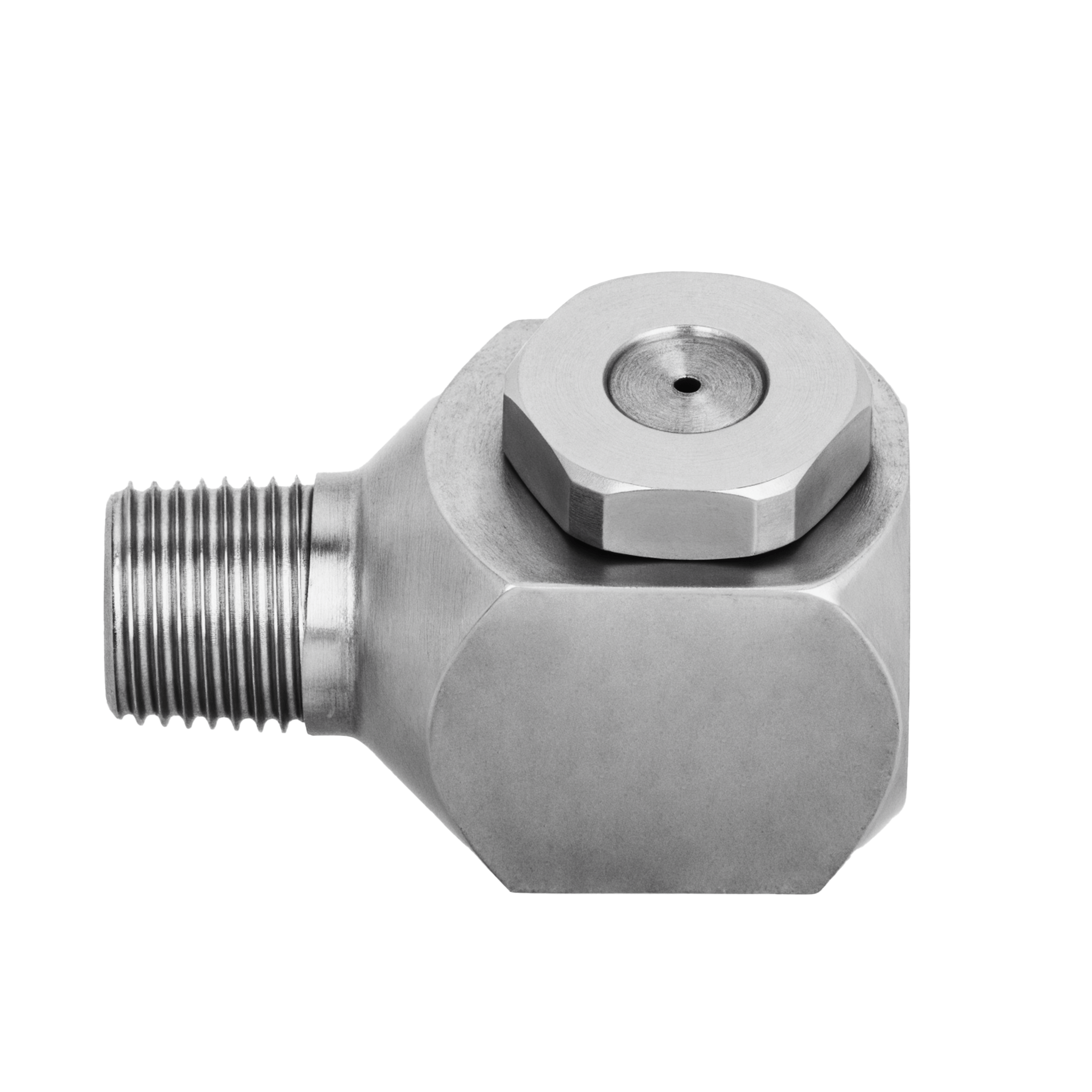

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPBX |

| Capacity Size | 25-25W |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | MALE (M) |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 7.5 |

| Orifice Diameter. Nom. (in) | 0.297 |

| Inlet Connection Size (in.) | 3/8 |

| Length (mm) | 40 |

| Length (in) | 1.563 |

| Inlet Dia. Nom. (in) | 0.297 |

| Max. Free Passage Dia. (mm) | 7.5 |

Description

Product Overview

When cement crews manage specialty applications, the NPBX-25-25W-3/8-316 lets each plant operator achieve consistent spray coverage with minimal downtime. Constructed from corrosion-resistant 316L stainless steel, this nozzle withstands harsh chemical exposure while maintaining structural integrity. The precision hollow cone spray pattern ensures uniform distribution, which helps reduce material waste and improve process efficiency. Operators rely on the NPBX-25-25W-3/8-316 to deliver predictable performance in demanding environments.

Applications

In cooling & quenching processes, the nozzle provides controlled spray intensity to protect equipment and maintain product quality. Its role in dust & pollution control supports regulatory compliance by optimizing particulate suppression and minimizing airborne contaminants.

Industries

Sectors such as automotive, building materials, and chemical processing utilize this nozzle for its durability and consistent output, while Energy and steel & metals industries benefit from its corrosion resistance in high-temperature environments. Breweries & wineries, cement, manufacturing & assembly, and meat & poultry operations incorporate the nozzle to address varied process needs requiring reliable fluid delivery.