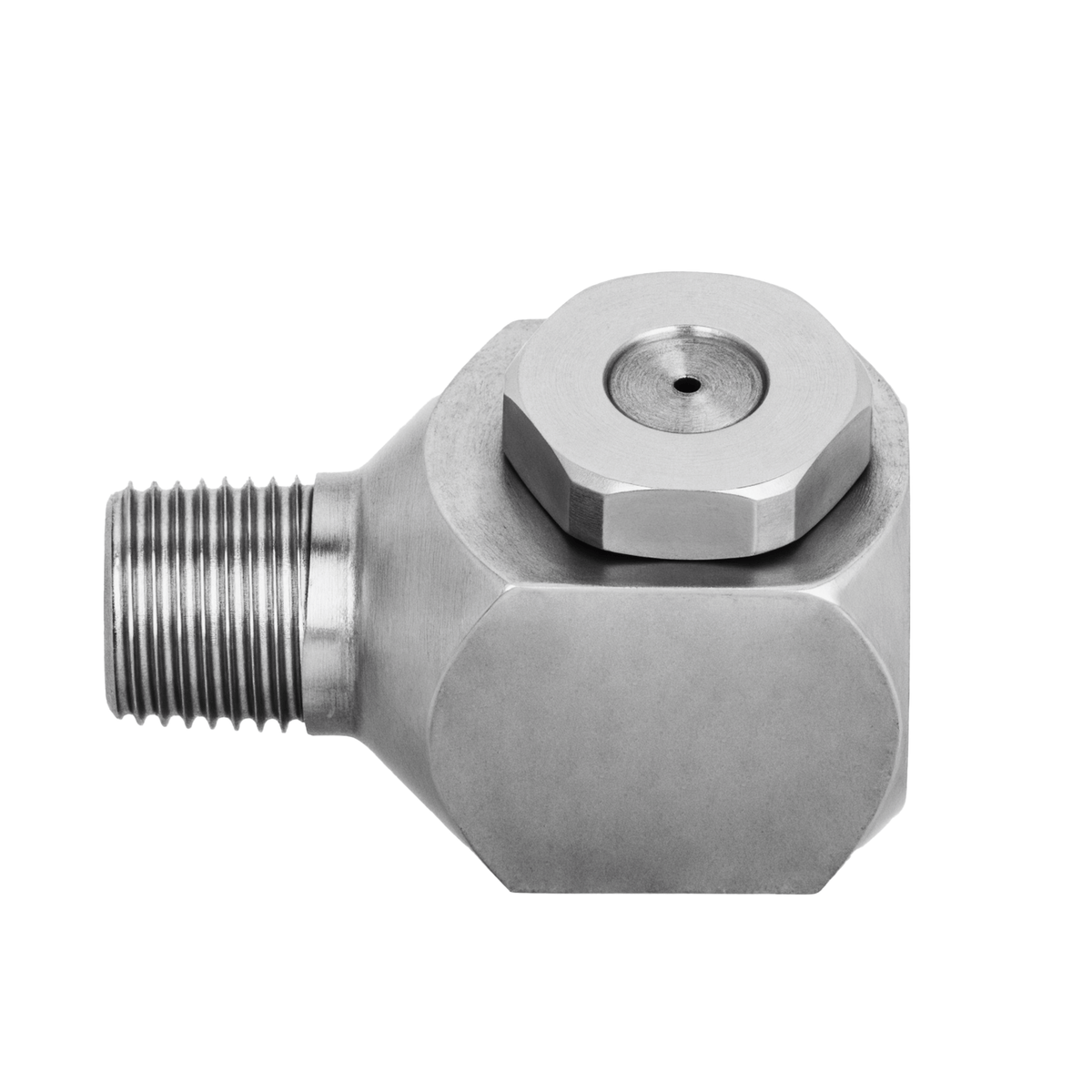

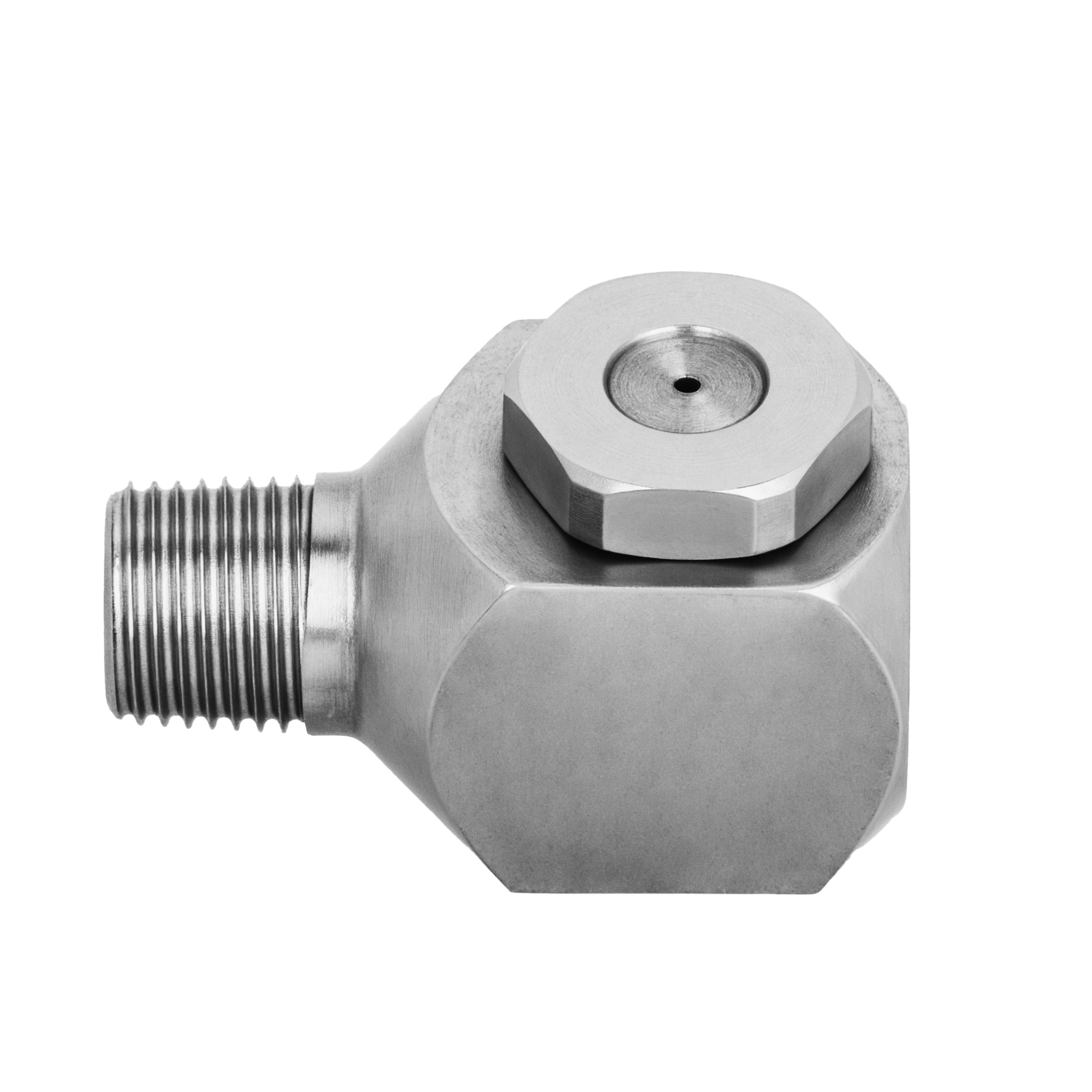

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPBX |

| Capacity Size | 2-3W |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | MALE (M) |

| Material Composition Filter | 303/304 stainless steel |

| Orifice Diameter. Nom. (mm) | 2 |

| Orifice Diameter. Nom. (in) | 0.109 |

| Inlet Connection Size (in.) | 1/8 |

| Length (mm) | 30.5 |

| Length (in) | 1.188 |

| Inlet Dia. Nom. (in) | 0.078 |

| Max. Free Passage Dia. (mm) | 2.8 |

Description

Product Overview

Inside the chemical processing line's specialty applications stage, a process engineer relies on the NPBX-2-3W-1/8-SS to deliver a consistent hollow cone spray pattern that ensures even coverage of target surfaces. Constructed from 303/304 stainless steel, the nozzle withstands corrosive environments while maintaining structural integrity. By integrating this nozzle with a 1/8-inch inlet, the operator achieves uniform atomization that improves process reliability and reduces material waste. This precision component aids in controlling fluid distribution critical to maintaining product quality.

Applications

In cooling & quenching operations, the nozzle's uniform hollow cone spray pattern helps regulate temperature rapidly and evenly across metal surfaces. For dust & pollution control, it atomizes liquids efficiently to suppress airborne particles, minimizing environmental impact and enhancing workplace safety.

Industries

Automotive, steel & metals, and building materials sectors often select this nozzle for its durability in harsh operational conditions and precise spray control. Additionally, chemical processing, breweries & wineries, and Energy industries benefit from its corrosion resistance and adaptability to diverse fluid handling needs.