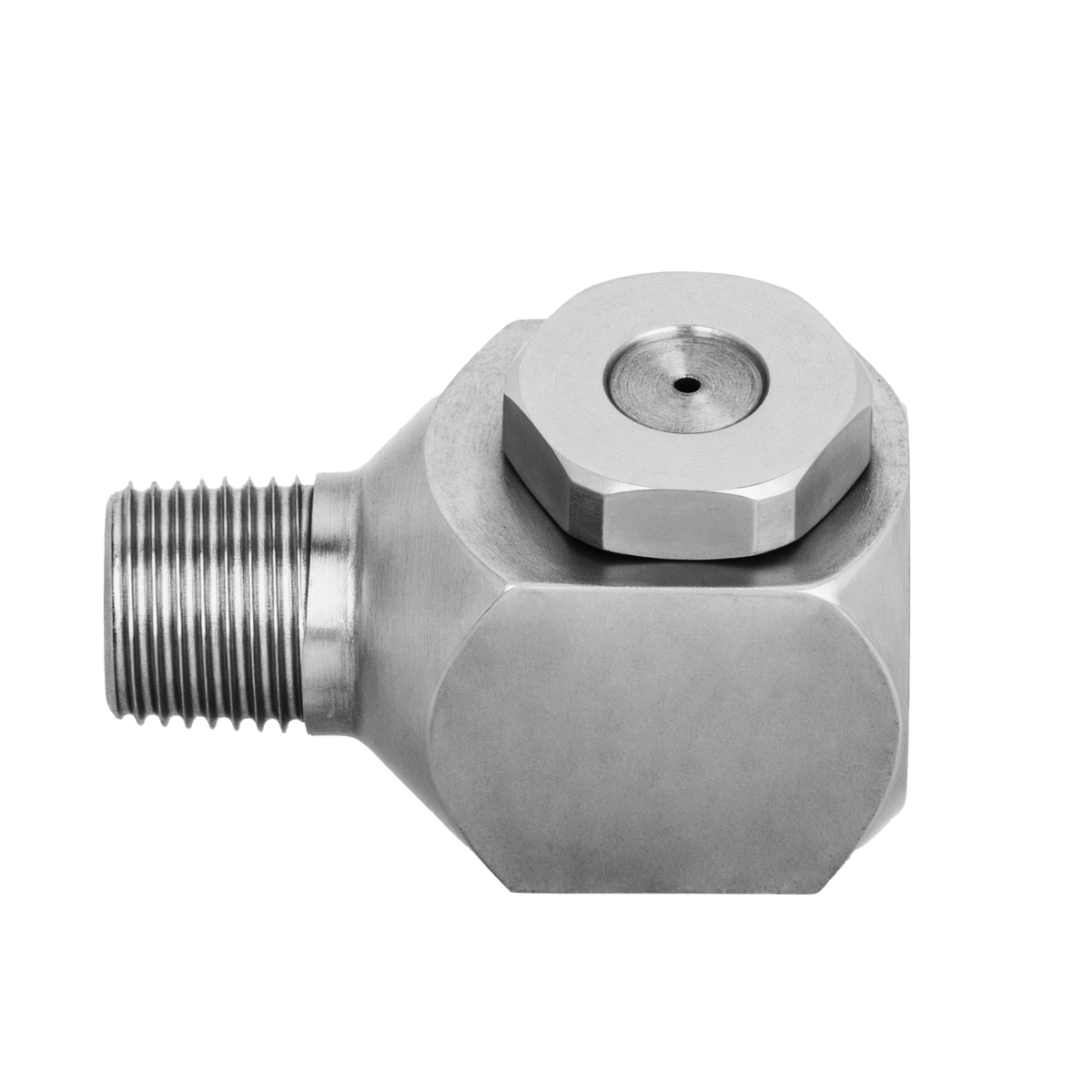

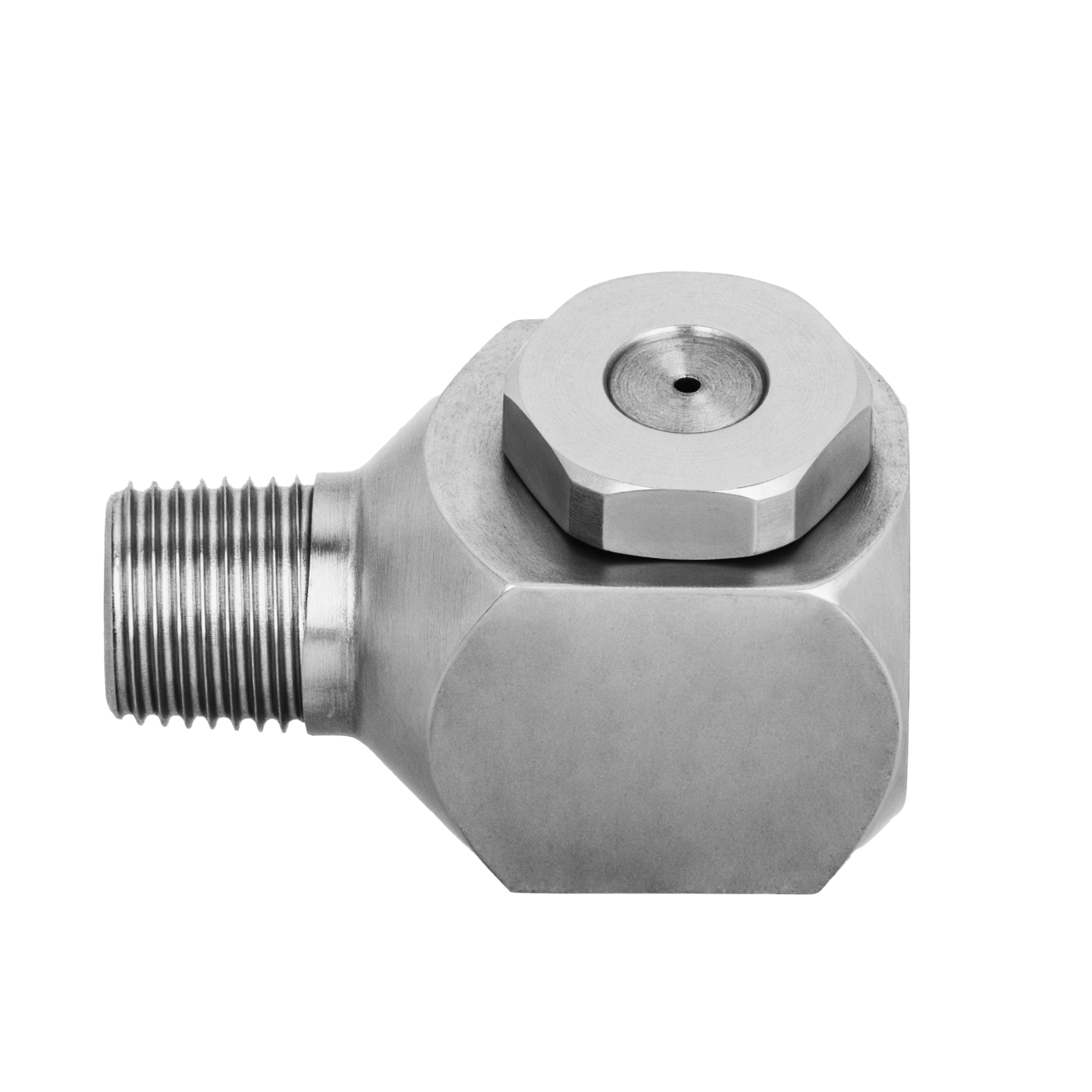

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPBX |

| Capacity Size | 2-3W |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | MALE (M) |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 2 |

| Orifice Diameter. Nom. (in) | 0.109 |

| Inlet Connection Size (in.) | 1/8 |

| Length (mm) | 30.5 |

| Length (in) | 1.188 |

| Inlet Dia. Nom. (in) | 0.078 |

| Max. Free Passage Dia. (mm) | 2.8 |

Description

Product Overview

During humidification & conditioning on a meat & poultry site, utilities coordinators trust the NPBX-2-3W-1/8-316 to deliver consistent spray distribution that supports environmental control standards. The unit's 316L stainless steel construction ensures resistance to corrosion in demanding conditions, while the precision hollow cone design produces a uniform mist crucial for maintaining product quality. Operators install the nozzle with a 1/8 inch inlet connection to integrate seamlessly into existing piping systems, achieving reliable coverage with measurable improvements in humidity regulation. The NPBX-2-3W-1/8-316's performance contributes to maintaining controlled atmospheres vital for operational efficiency.

Applications

In cooling & quenching processes, the nozzle's uniform hollow cone spray pattern helps regulate temperature effectively, reducing thermal stress on materials. Additionally, its role in dust & pollution control supports cleaner work environments by minimizing airborne particulates through consistent atomization.

Industries

Sectors such as automotive, building materials, and chemical processing rely on this nozzle for stable spray performance under corrosive or high-demand conditions. The Energy, steel & metals, and breweries & wineries industries also benefit from its durability and precision, using it to enhance process control and environmental management.