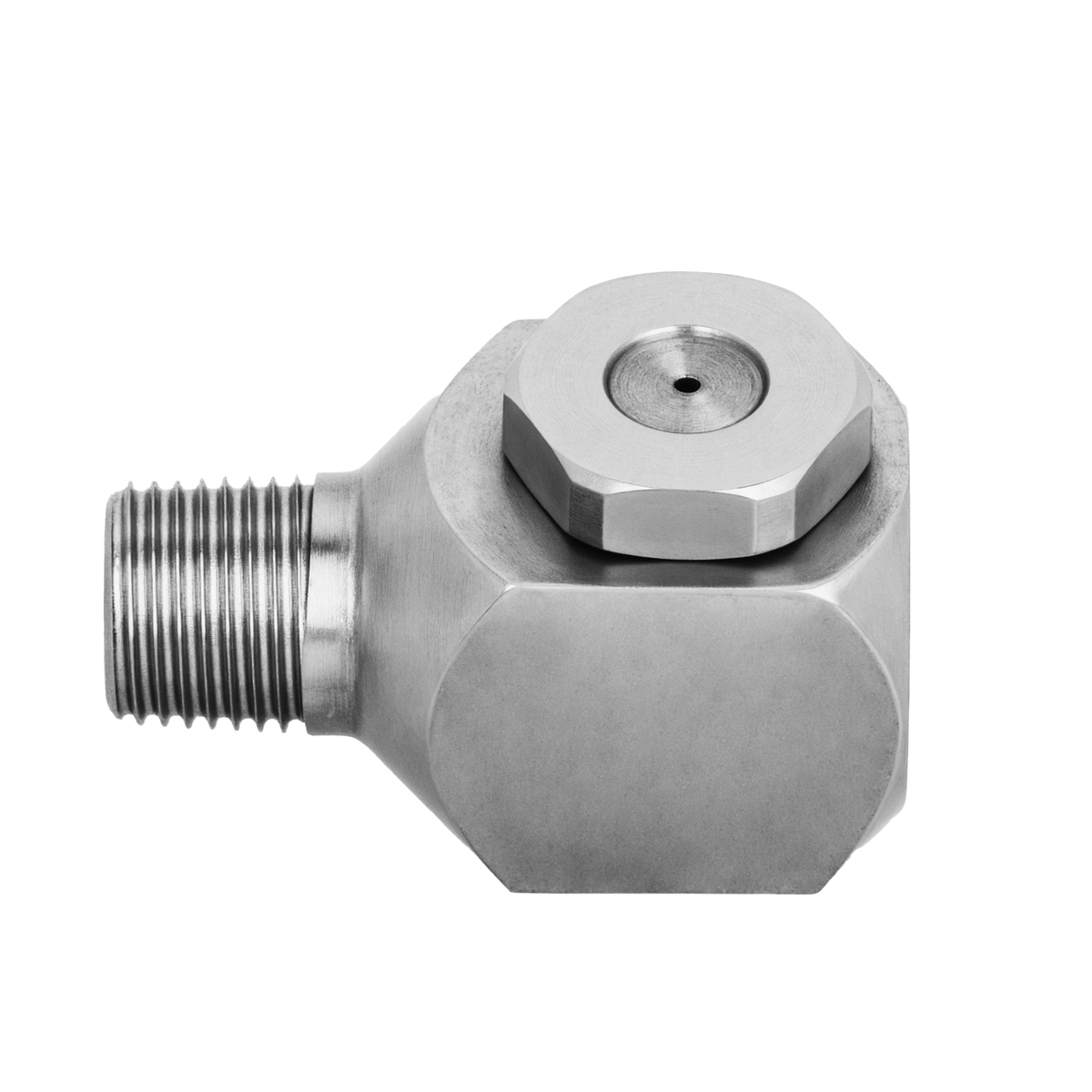

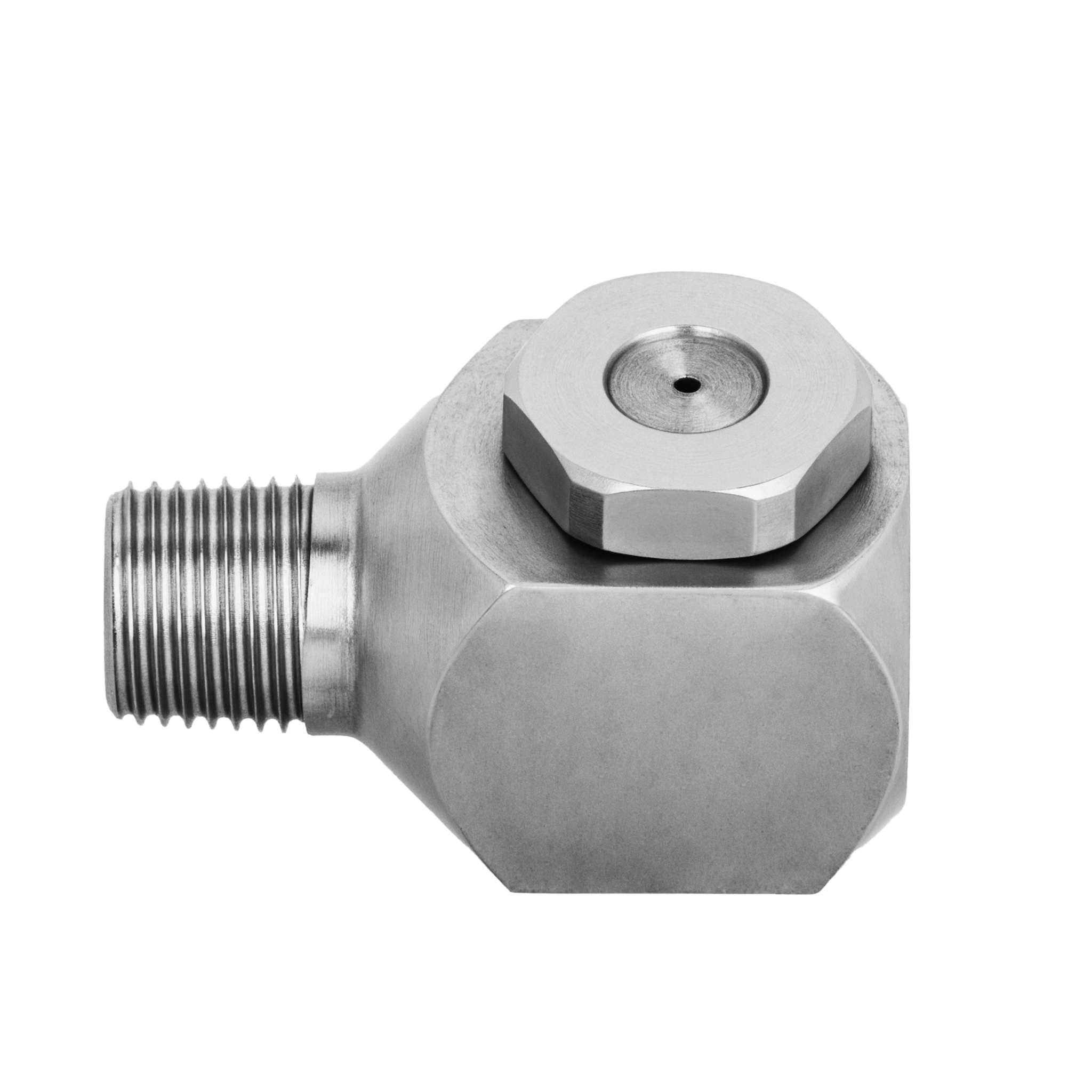

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPBX |

| Capacity Size | 2-10W |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | MALE (M) |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 2 |

| Orifice Diameter. Nom. (in) | 0.172 |

| Inlet Connection Size (in.) | 1/8 |

| Length (mm) | 30.5 |

| Length (in) | 1.188 |

| Inlet Dia. Nom. (in) | 0.078 |

| Max. Free Passage Dia. (mm) | 4.4 |

Description

Product Overview

During cooling & quenching on a steel & metals site, quality managers trust the NPBX-2-10W-1/8-316 to deliver consistent spray coverage essential for maintaining material integrity. Constructed from 316l stainless steel, this nozzle resists corrosion in harsh environments, extending service life and reducing maintenance intervals. Its precision hollow cone design ensures uniform droplet distribution, which enhances heat transfer efficiency and controls thermal gradients during quenching. Operators rely on the 1/8 inlet for easy integration with existing fluid delivery systems, enabling controlled flow rates and repeatable results.

Applications

The NPBX-2-10W-1/8-316 is often deployed in cooling & quenching processes where uniform spray patterns help optimize temperature reduction and minimize microstructural defects. It also supports dust & pollution control efforts by providing fine atomization that captures particulate matter, improving workplace safety and environmental compliance.

Industries

This nozzle is favored across automotive, chemical processing, and breweries & wineries sectors for its corrosion resistance and consistent spray performance under varying operational conditions. Additionally, manufacturing & assembly and building materials industries benefit from its ability to maintain process reliability in demanding environments, while Energy and cement applications appreciate its durability and precision.