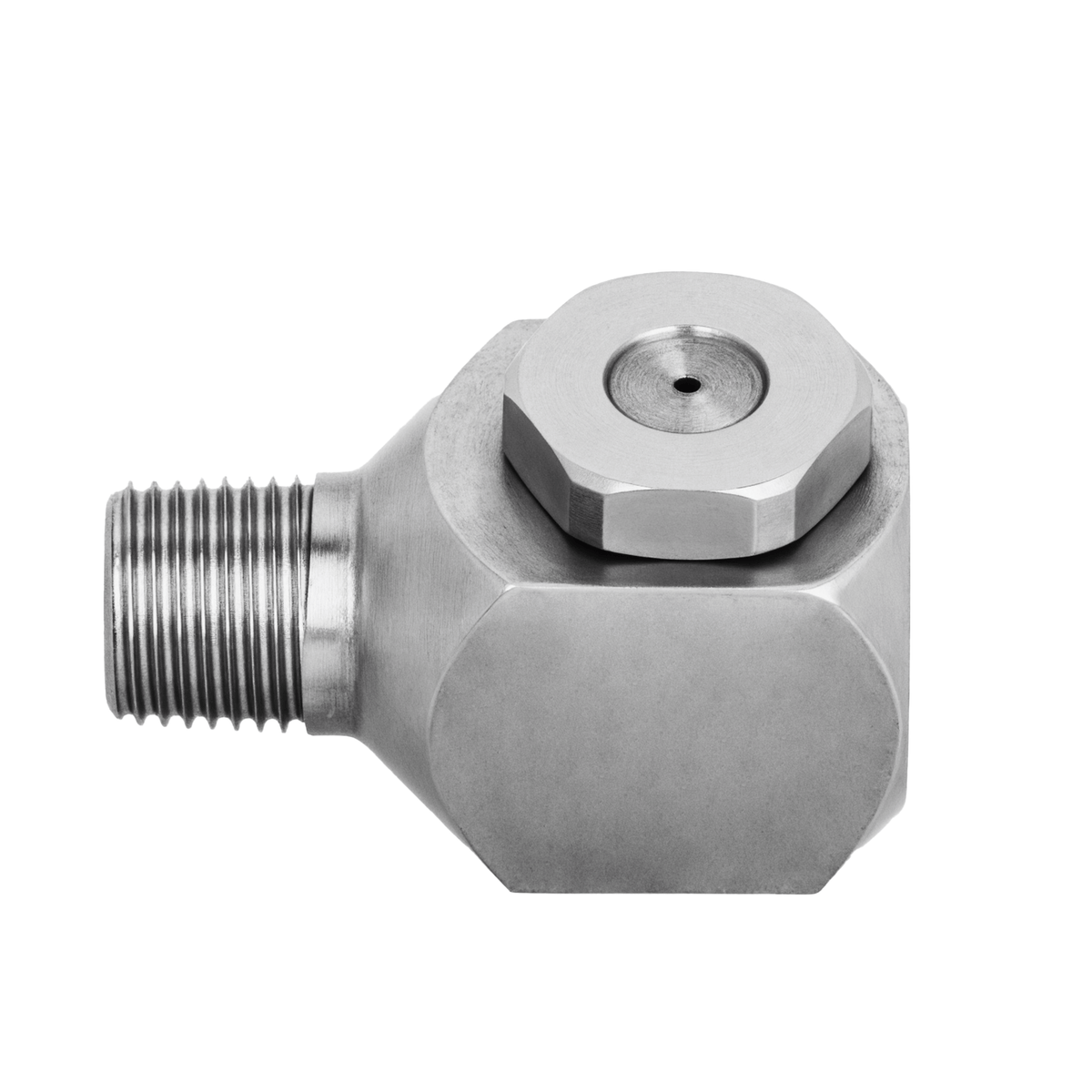

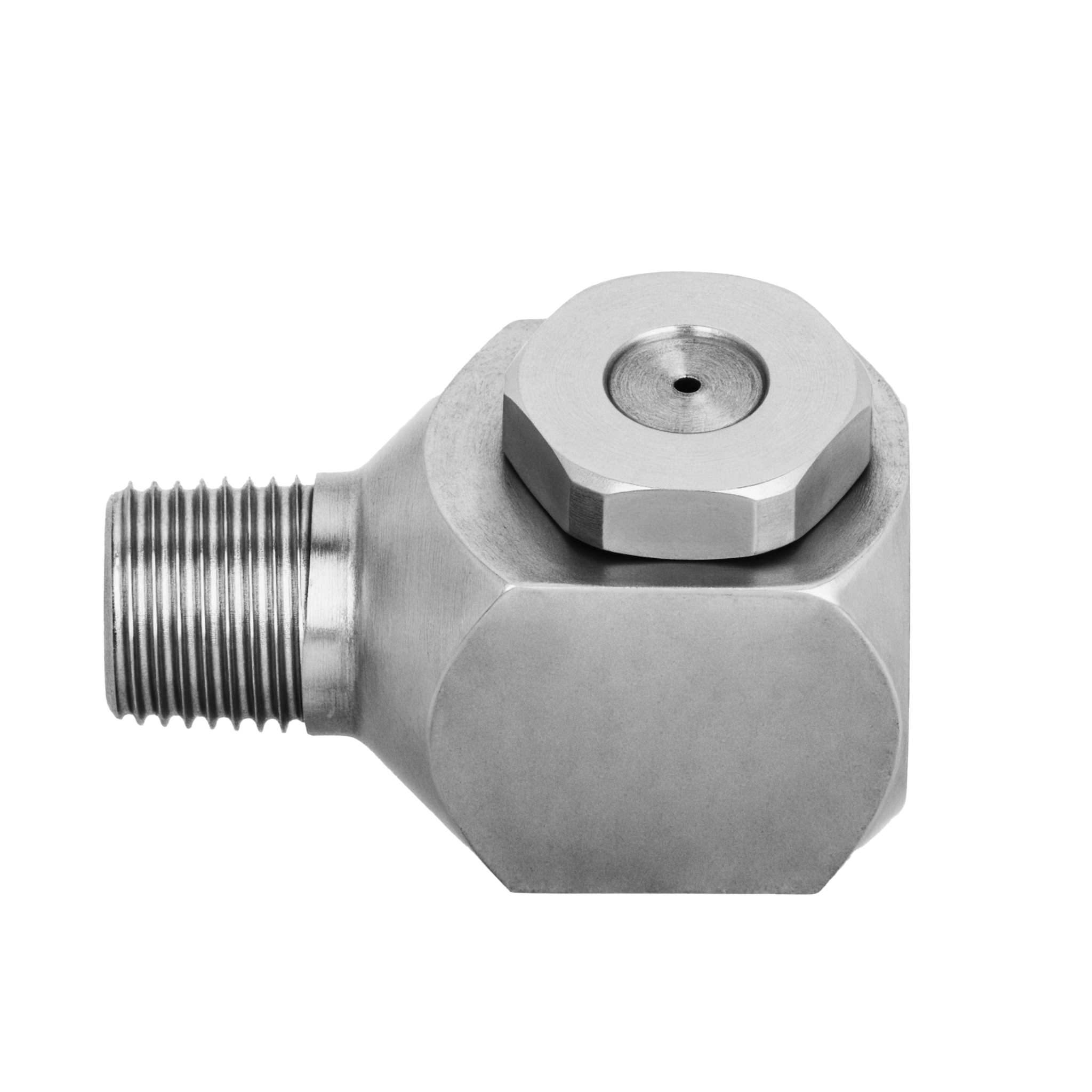

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPBX |

| Capacity Size | 2-10W |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | MALE (M) |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 2 |

| Orifice Diameter. Nom. (in) | 0.172 |

| Inlet Connection Size (in.) | 1/4 |

| Length (mm) | 35 |

| Length (in) | 1.375 |

| Inlet Dia. Nom. (in) | 0.078 |

| Max. Free Passage Dia. (mm) | 4.4 |

Description

Product Overview

Inside the manufacturing & assembly line's dust & pollution control stage, a plant operator relies on the NPBX-2-10W-1/4-316 to deliver consistent spray coverage while resisting corrosion from harsh environments. The operator installs the nozzle, constructed from 316L stainless steel, onto a system with a 1/4-inch inlet to achieve a uniform hollow cone spray pattern. This precision spray formation helps maintain air quality by effectively capturing airborne particulates. Over time, the nozzle's durability reduces maintenance intervals and minimizes downtime in the production process.

Applications

In cooling & quenching processes, the nozzle ensures rapid temperature reduction by evenly distributing liquid over hot surfaces, which helps improve material properties downstream. Additionally, its role in dust & pollution control minimizes particulate emissions, supporting compliance with environmental regulations and protecting worker health.

Industries

Automotive, building materials, and chemical processing sectors utilize this nozzle for its balance of corrosion resistance and spray uniformity, essential for rigorous operational requirements. Energy, steel & metals, breweries & wineries, cement, manufacturing & assembly, and meat & poultry industries also depend on its reliability to support processes involving humidification & conditioning and other specialty applications.