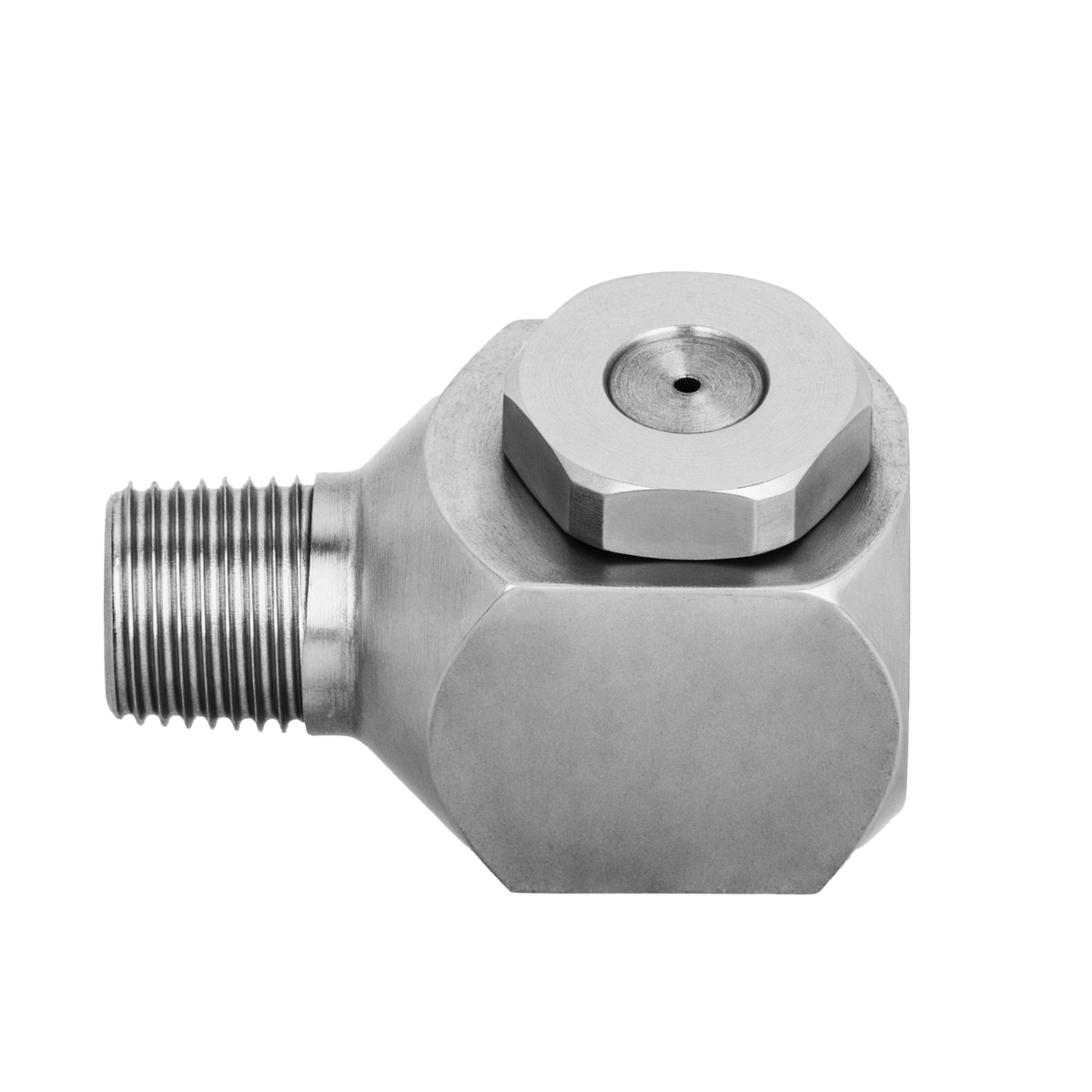

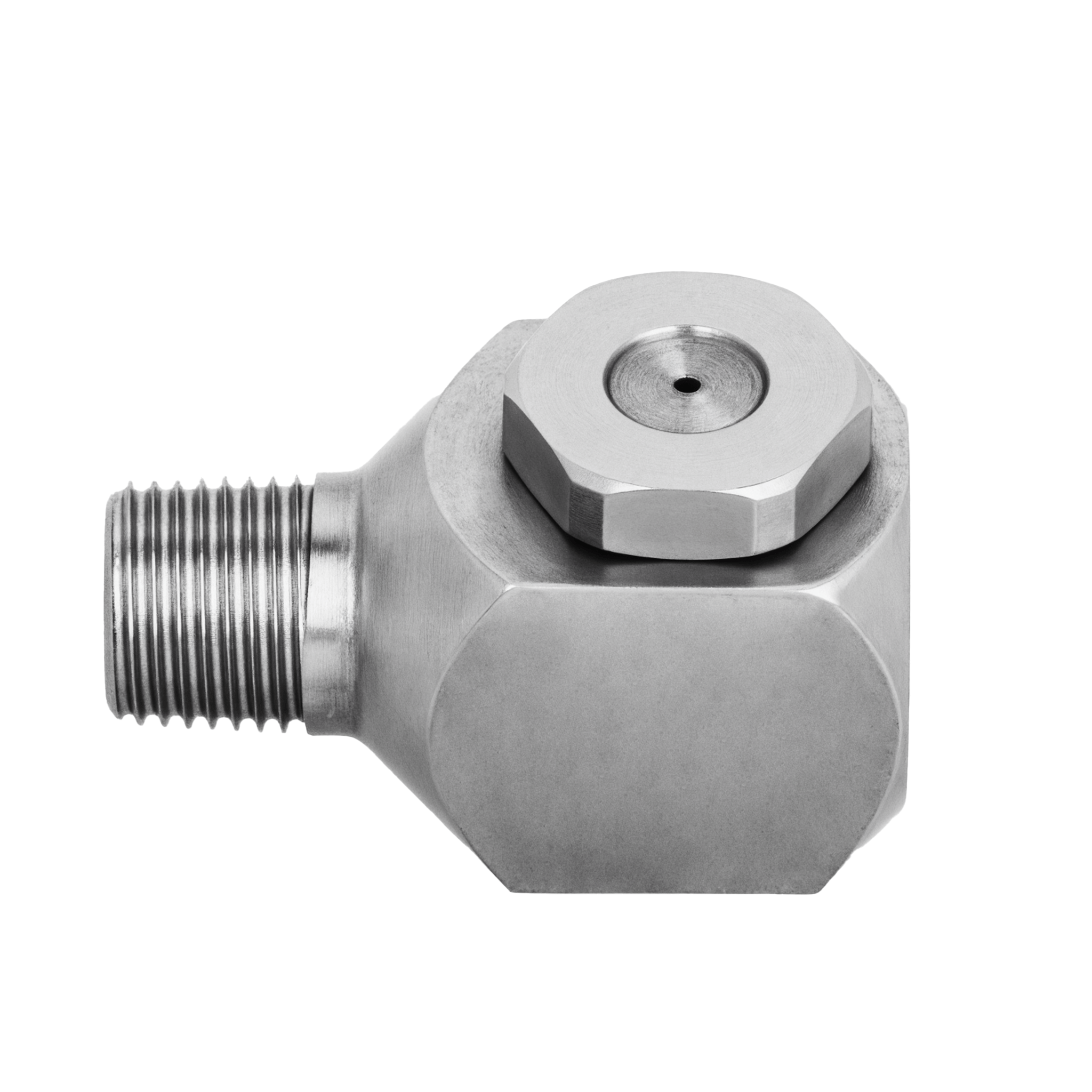

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPBX |

| Capacity Size | 15-15W |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | MALE (M) |

| Material Composition Filter | 303/304 stainless steel |

| Orifice Diameter. Nom. (mm) | 6 |

| Orifice Diameter. Nom. (in) | 0.219 |

| Inlet Connection Size (in.) | 3/8 |

| Length (mm) | 40 |

| Length (in) | 1.563 |

| Inlet Dia. Nom. (in) | 0.234 |

| Max. Free Passage Dia. (mm) | 5.6 |

Description

Product Overview

Inside the manufacturing & assembly line's cooling & quenching stage, a plant operator relies on the NPBX-15-15W-3/8-SS to deliver consistent liquid distribution over metal parts. Constructed from durable 303/304 stainless steel, this nozzle's hollow cone design ensures an even spray pattern that minimizes hotspots and improves cooling uniformity. The 3/8-inch inlet facilitates straightforward integration with existing piping systems, while the corrosion-resistant material extends service life in harsh environments. Operators monitor fluid flow and temperature reduction to verify that the nozzle meets process specifications for quenching efficiency.

Applications

In cooling & quenching processes, the nozzle provides a uniform spray that helps maintain material integrity by controlling thermal gradients. It also supports dust & pollution control by atomizing liquids effectively to capture airborne particles, reducing emissions and improving workplace safety.

Industries

The NPBX-15-15W-3/8-SS is favored in automotive and steel & metals sectors for its ability to withstand corrosive fluids while delivering reliable spray performance. Additionally, industries such as chemical processing, cement, and breweries & wineries utilize this nozzle to address diverse process requirements, benefiting from its corrosion resistance and adaptable spray characteristics.