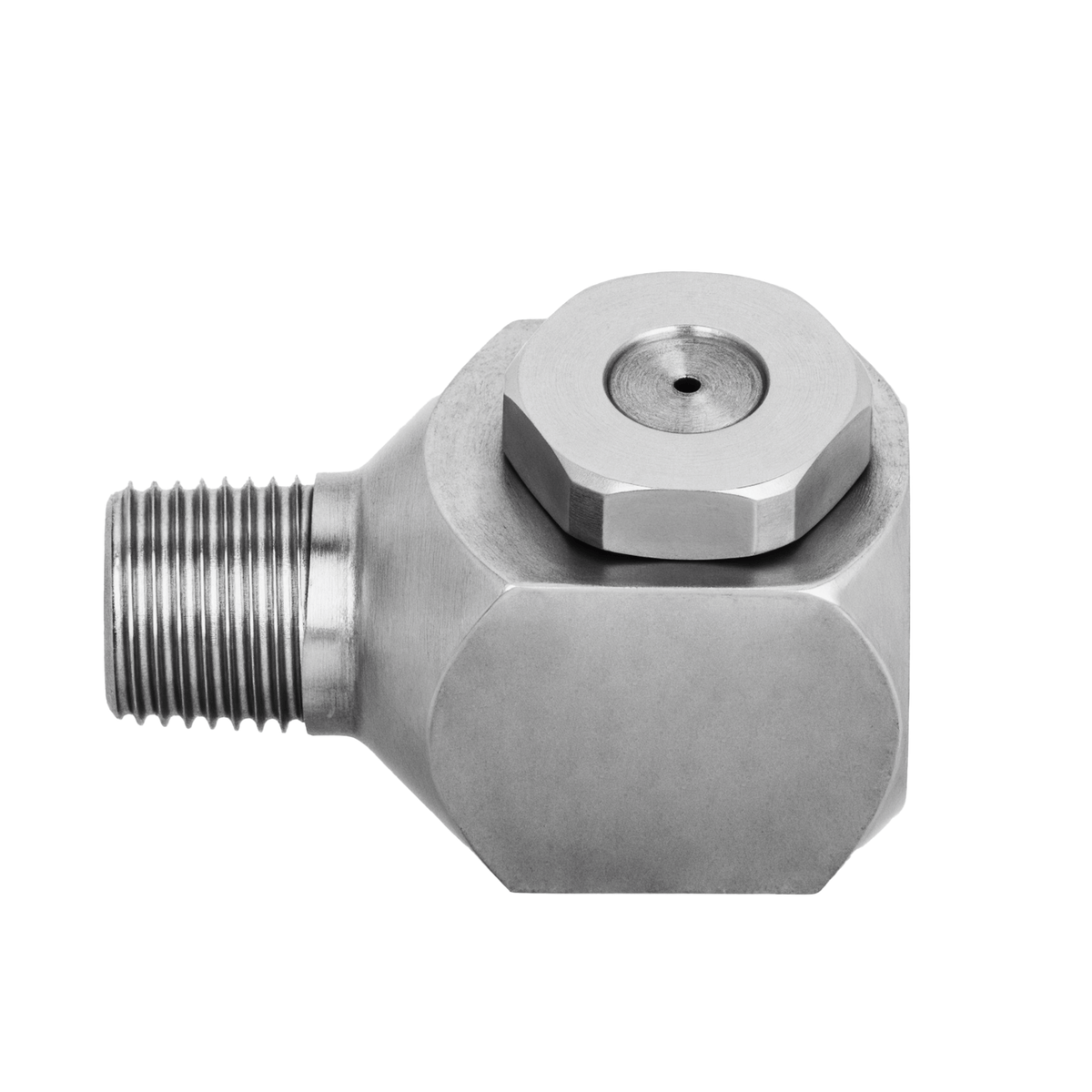

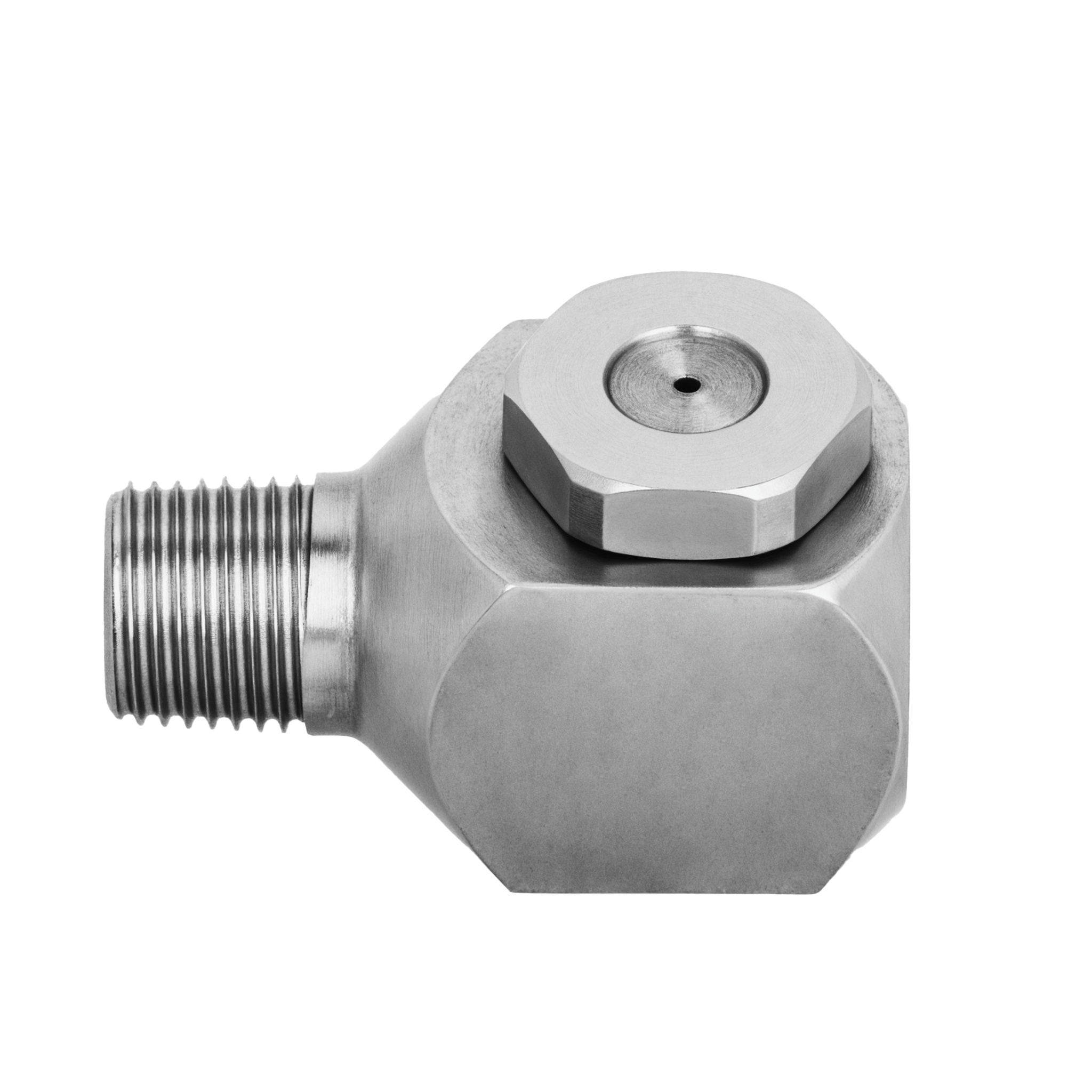

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPBX |

| Capacity Size | 10-10W |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | MALE (M) |

| Material Composition Filter | 303/304 stainless steel |

| Orifice Diameter. Nom. (mm) | 5.2 |

| Orifice Diameter. Nom. (in) | 0.172 |

| Inlet Connection Size (in.) | 3/8 |

| Length (mm) | 40 |

| Length (in) | 1.563 |

| Inlet Dia. Nom. (in) | 0.203 |

| Max. Free Passage Dia. (mm) | 4.4 |

Description

Product Overview

When meat & poultry crews manage cooling & quenching, the NPBX-10-10W-3/8-SS lets each process engineer deliver consistent and controlled spray coverage critical to maintaining product quality. Constructed from 303/304 stainless steel, this nozzle resists corrosion in harsh environments while the hollow cone spray pattern ensures uniform droplet distribution. Operators install the NPBX-10-10W-3/8-SS with its 3/8-inch inlet to precisely regulate flow rates, helping reduce water usage and improve thermal transfer efficiency during operation.

Applications

In cooling & quenching applications, the nozzle's uniform spray pattern supports rapid temperature reduction and helps prevent surface defects. Additionally, its role in dust & pollution control minimizes airborne particulates, enhancing workplace safety and meeting regulatory standards.

Industries

The nozzle is commonly used across automotive, building materials, and chemical processing industries, where controlled spraying processes affect product consistency and equipment longevity. Its durability and corrosion resistance also make it suitable for Energy, steel & metals, breweries & wineries, cement, and manufacturing & assembly operations that demand reliable nozzle performance under variable conditions.