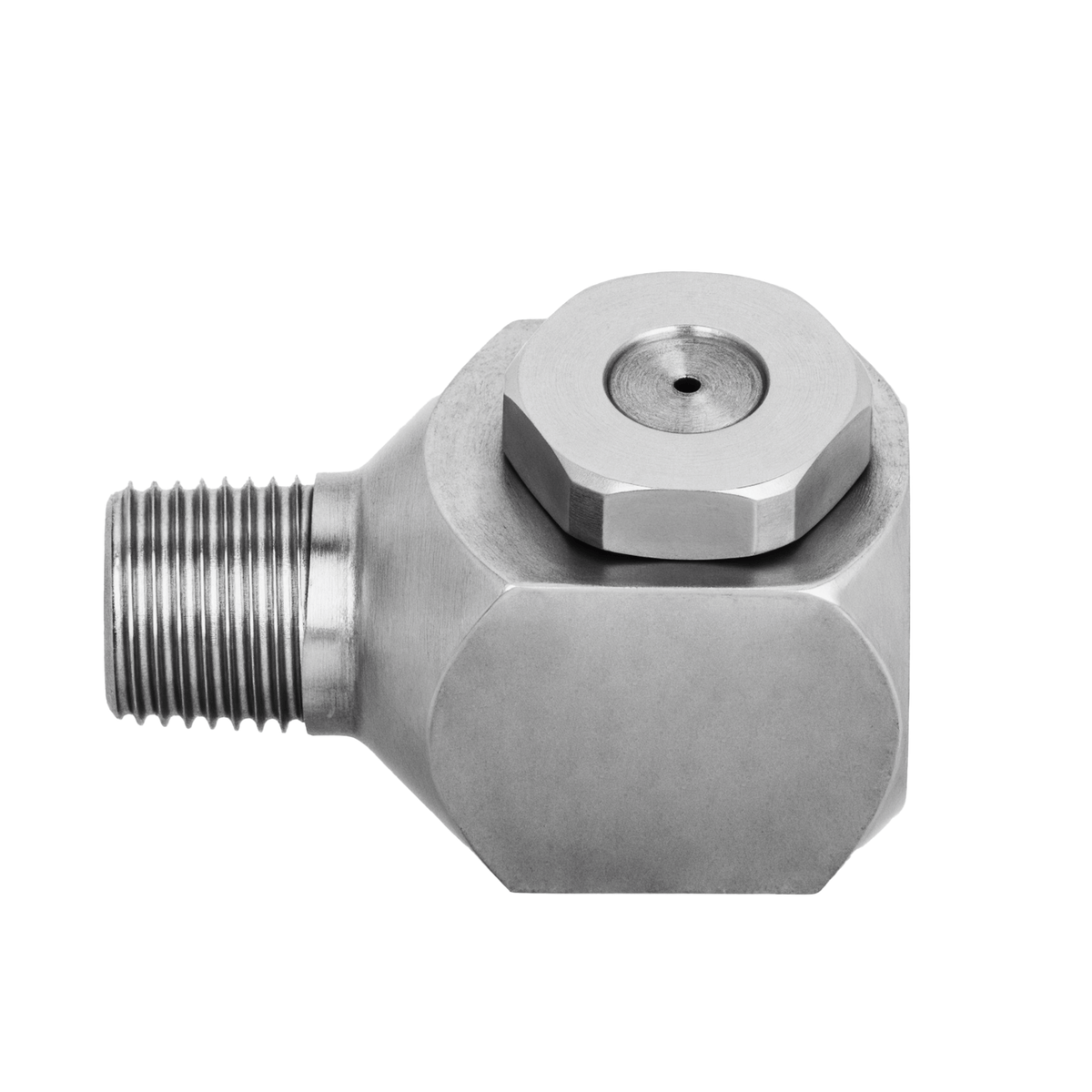

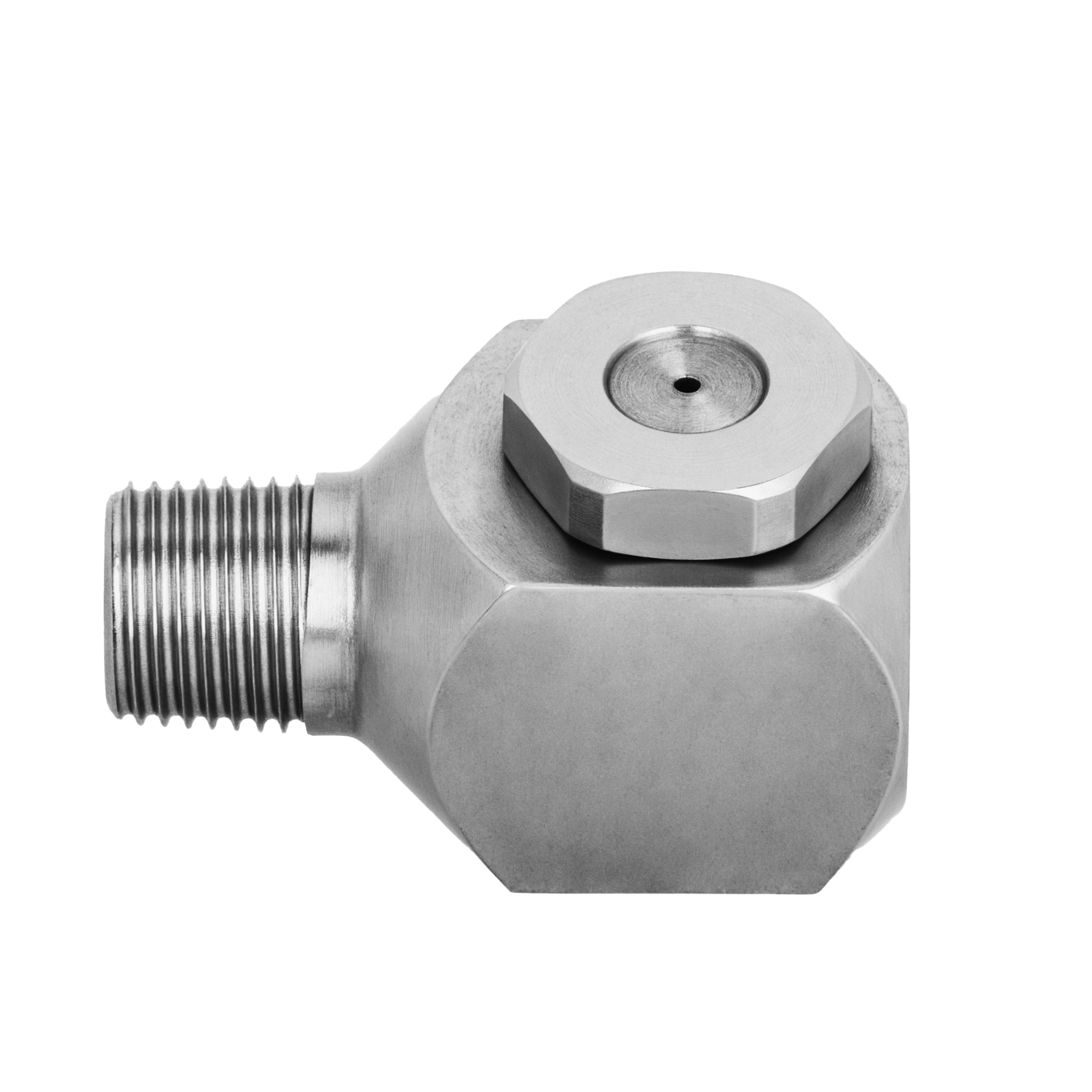

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPBX |

| Capacity Size | 10-10W |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | MALE (M) |

| Material Composition Filter | 303/304 stainless steel |

| Orifice Diameter. Nom. (mm) | 4.8 |

| Orifice Diameter. Nom. (in) | 0.172 |

| Inlet Connection Size (in.) | 1/4 |

| Length (mm) | 35 |

| Length (in) | 1.375 |

| Inlet Dia. Nom. (in) | 0.188 |

| Max. Free Passage Dia. (mm) | 4.4 |

Description

Product Overview

A maintenance supervisor in the Energy facility uses the NPBX-10-10W-1/4-SS during cooling & quenching to deliver a consistent hollow cone spray pattern essential for temperature control. Constructed from 303/304 stainless steel, the nozzle resists corrosion in harsh environments, ensuring long service life. By integrating this nozzle into the quenching process, the operator achieves uniform coverage that stabilizes metal properties and reduces downtime caused by uneven cooling.

Applications

In cooling & quenching, the uniform spray distribution of the nozzle minimizes thermal gradients, improving product quality and equipment longevity. Additionally, its use in dust & pollution control helps suppress airborne particulates, leading to safer work environments and compliance with regulatory standards.

Industries

Sectors such as automotive, building materials, and steel & metals rely on this nozzle for processes requiring precise fluid application and durability under continuous operation. Energy, chemical processing, and manufacturing & assembly facilities also value the corrosion resistance and spray consistency the nozzle provides across varying production demands.