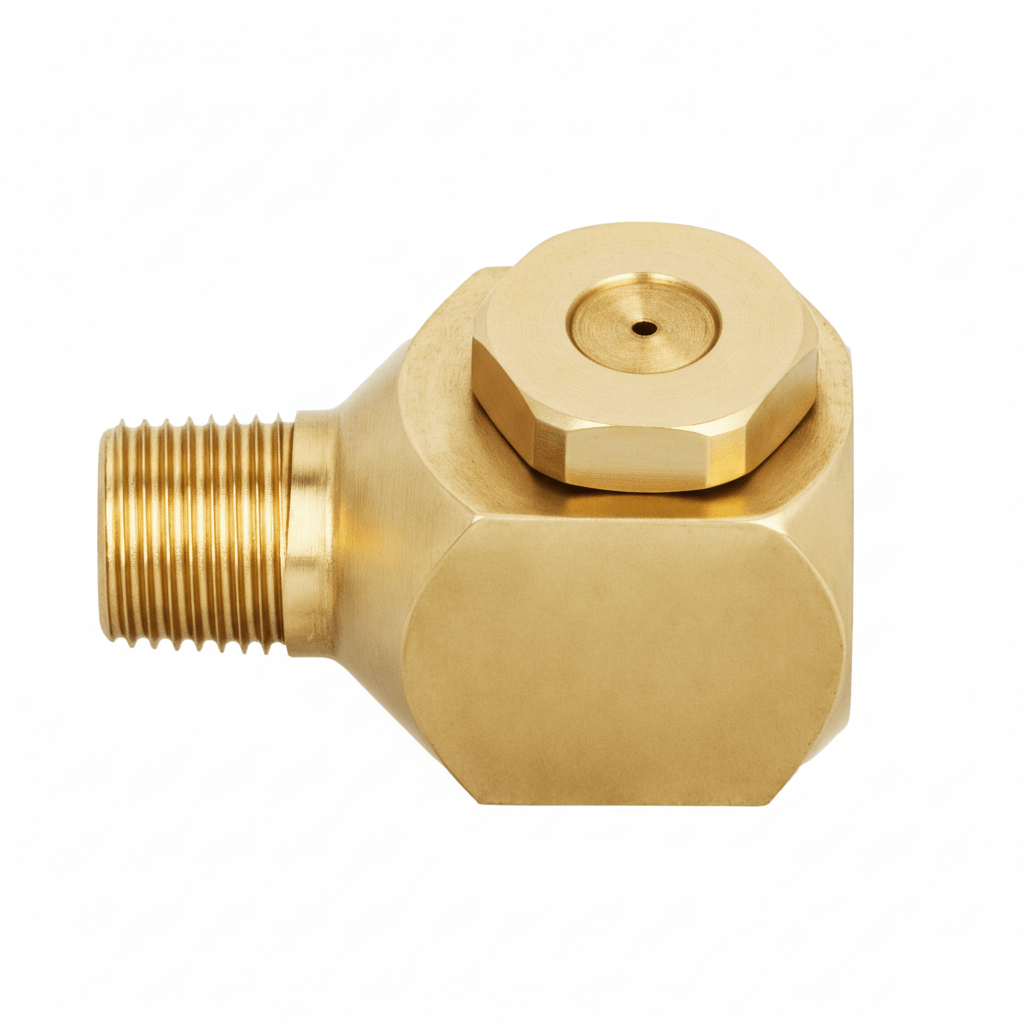

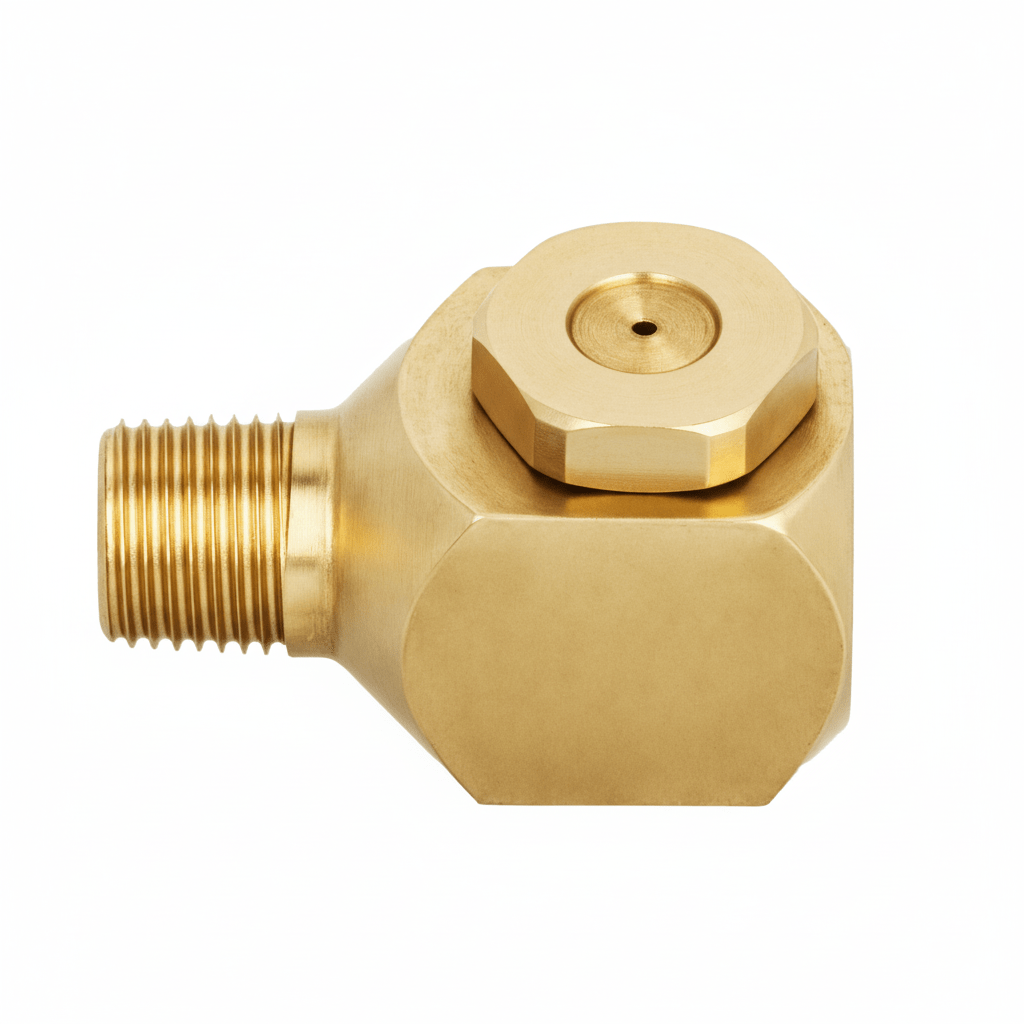

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPBX |

| Capacity Size | 1-15W |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | MALE (M) |

| Material Composition Filter | Brass |

| Orifice Diameter. Nom. (mm) | 1.6 |

| Orifice Diameter. Nom. (in) | 0.219 |

| Inlet Connection Size (in.) | 1/4 |

| Length (mm) | 35 |

| Length (in) | 1.375 |

| Inlet Dia. Nom. (in) | 0.063 |

| Max. Free Passage Dia. (mm) | 5.6 |

Description

Product Overview

A plant operator in the meat & poultry facility uses the NPBX-1-15W-1/4 during dust & pollution control to deliver a consistent hollow cone spray that promotes even coverage across the processing area. Constructed from brass, the nozzle resists corrosion from exposure to cleaning chemicals and humid environments, extending service life. The 1/4 inlet size allows straightforward integration into existing fluid systems, enabling precise control of spray distribution and volume to maintain air quality standards. This nozzle ensures reliable operation under continuous use, minimizing downtime and maintenance.

Applications

In cooling & quenching processes, the NPBX-1-15W-1/4 provides a uniform spray pattern that efficiently reduces surface temperatures, protecting metal parts during manufacturing. Its role in humidification & conditioning helps maintain controlled environments by delivering finely atomized water droplets that stabilize moisture levels, supporting product quality and operational consistency.

Industries

Sectors such as automotive, chemical processing, and steel & metals rely on this nozzle for its ability to withstand harsh industrial conditions while delivering consistent spray performance. Additionally, industries including breweries & wineries, building materials, and Energy utilize the NPBX-1-15W-1/4 to address diverse requirements from dust suppression to process cooling within their workflows