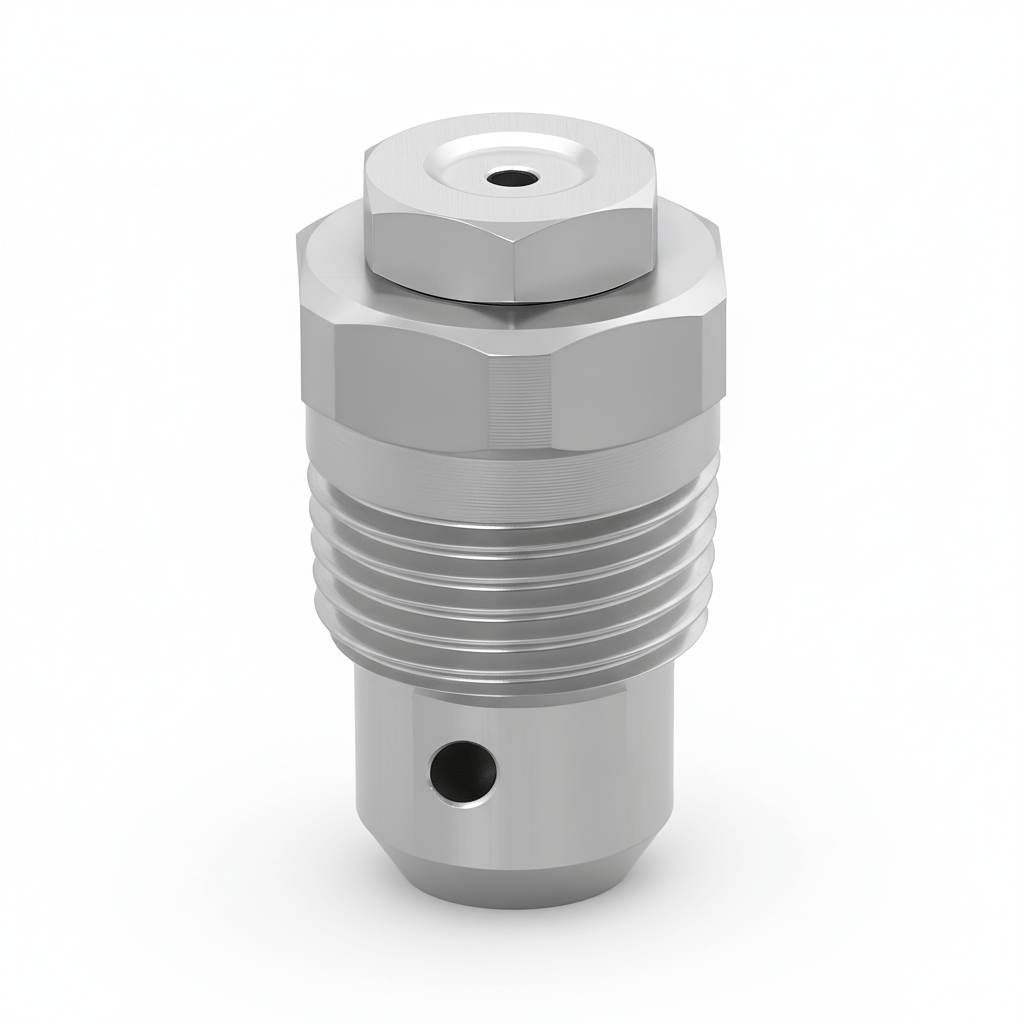

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPBD |

| Capacity Size | 8 |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | MALE (M) |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 4 |

| Orifice Diameter. Nom. (in) | 0.156 |

| Inlet Connection Size (in.) | 3/8 |

| Hex Size (mm) | 17.5 |

| Inlet Dia. Nom. (mm) | 4 |

| Inlet Dia. Nom. (in) | 0.156 |

Description

Product Overview

During cooling & quenching on a Energy site, process engineers trust the NPBD-8-3/8-316 to deliver consistent spray coverage critical for temperature regulation. Constructed from 316L stainless steel, this nozzle resists corrosion in harsh environments, extending service life and reducing maintenance intervals. Its precision hollow cone design ensures uniform droplet size distribution, optimizing cooling efficiency and minimizing thermal stress on components. Operators often calibrate flow rates through the 3/8 inlet to maintain process stability under variable operating conditions.

Applications

In cooling & quenching processes, the nozzle supports controlled heat dissipation to protect equipment integrity and extend component lifespan. Additionally, it plays a role in dust & pollution control by generating fine sprays that suppress airborne particles, improving workplace safety and compliance.

Industries

The NPBD-8-3/8-316 is favored across building materials, mining, and cement sectors due to its durability and consistent spray performance. These industries demand reliable equipment capable of handling abrasive materials and corrosive atmospheres, making this nozzle a practical choice for manufacturing & assembly and roofing applications as well.