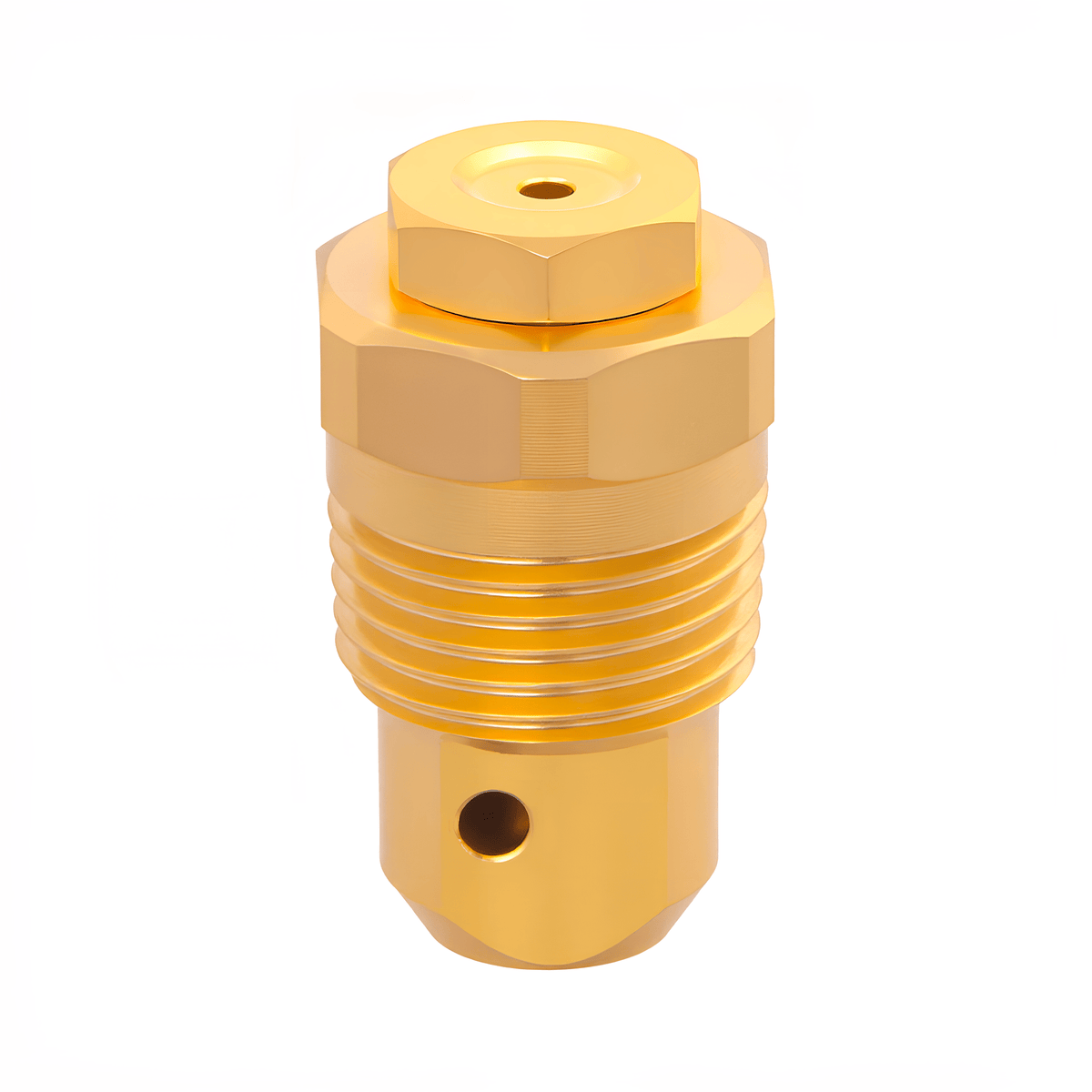

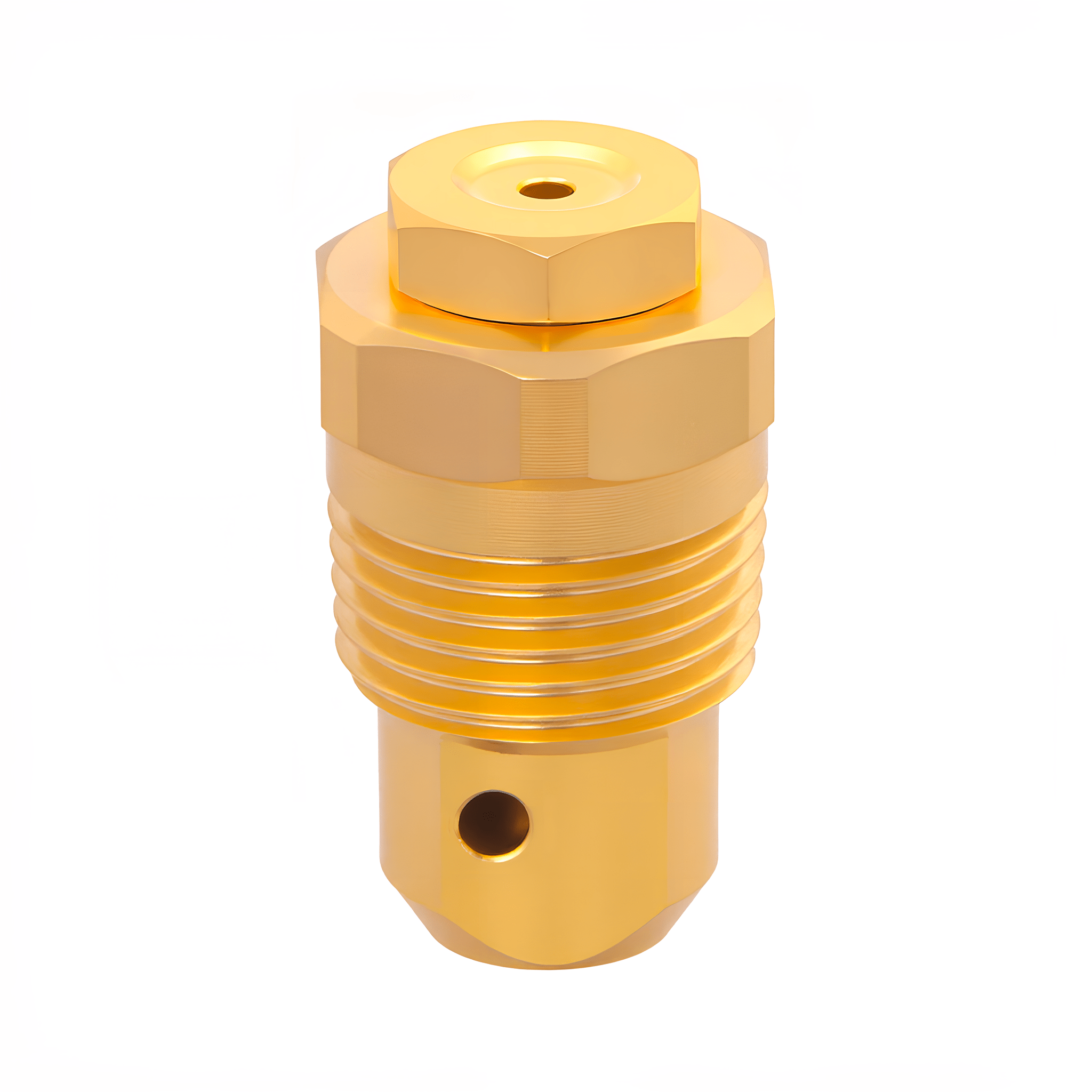

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPBD |

| Capacity Size | 70 |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | MALE (M) |

| Material Composition Filter | Brass |

| Orifice Diameter. Nom. (mm) | 12.7 |

| Orifice Diameter. Nom. (in) | 0.5 |

| Inlet Connection Size (in.) | 1-1/2 |

| Hex Size (mm) | 50.8 |

| Inlet Dia. Nom. (mm) | 9.5+ |

| Inlet Dia. Nom. (in) | 0.375* |

Description

Product Overview

During specialty applications on a cement site, quality managers trust the NPBD-70-1-1/2 to deliver a consistent hollow cone spray pattern that optimizes coverage and material usage. Made from brass with a 1-1/2 inlet, this nozzle maintains performance under corrosive conditions common in abrasive environments. Operators rely on its uniform droplet distribution to enhance cooling efficiency and reduce dust generation, directly impacting process stability and equipment longevity. Precise flow control measurable through spray angle and distribution consistency ensures repeatable results across multiple production cycles.

Applications

In cooling & quenching operations, the NPBD-70-1-1/2 nozzle supports controlled temperature reduction critical to material properties and downstream processing. It is also utilized in dust & pollution control systems where its uniform spray mitigates airborne particulates, improving workplace safety and environmental compliance.

Industries

The nozzle is widely applied in building materials, Energy, mining, cement, manufacturing & assembly, and roofing sectors due to its resistance to wear and corrosion in harsh industrial settings. These industries benefit from the nozzle's ability to maintain spray uniformity and reliability under continuous operation, helping to streamline production and reduce downtime.