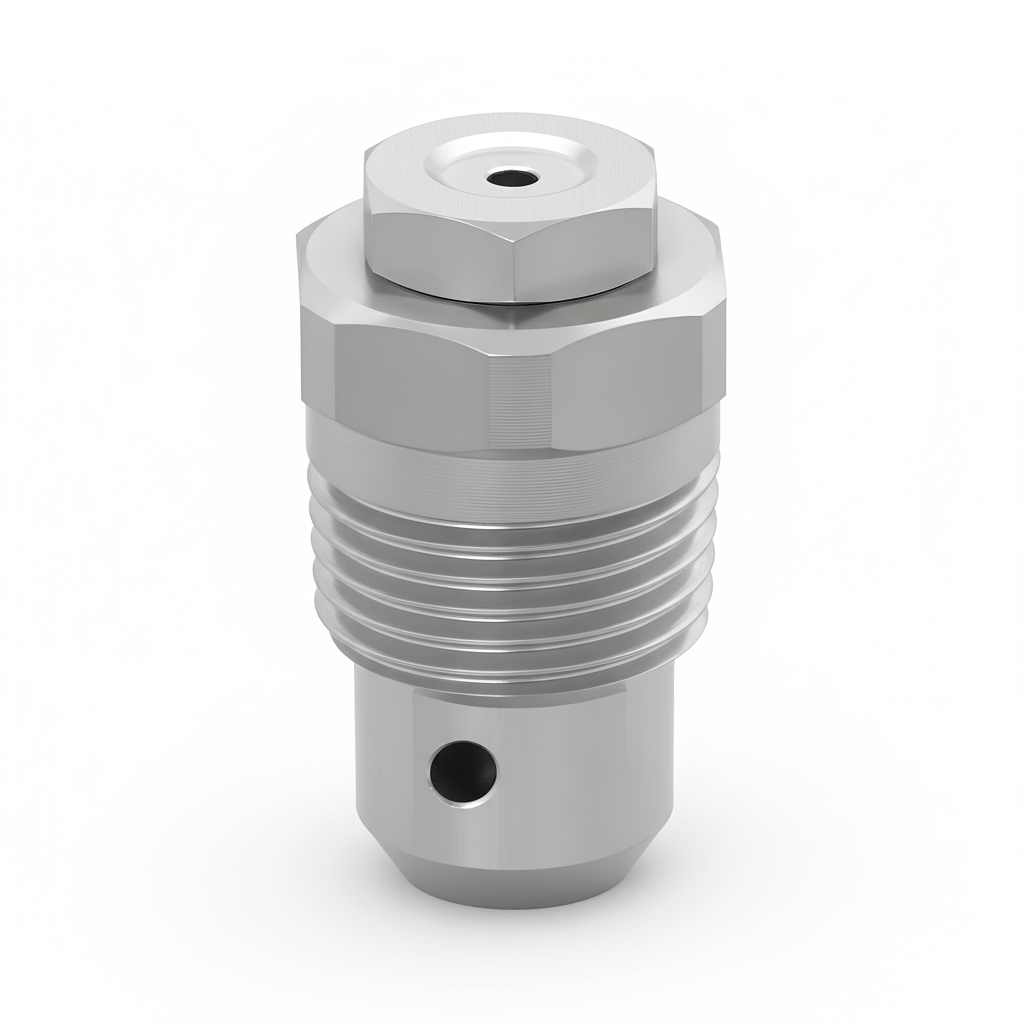

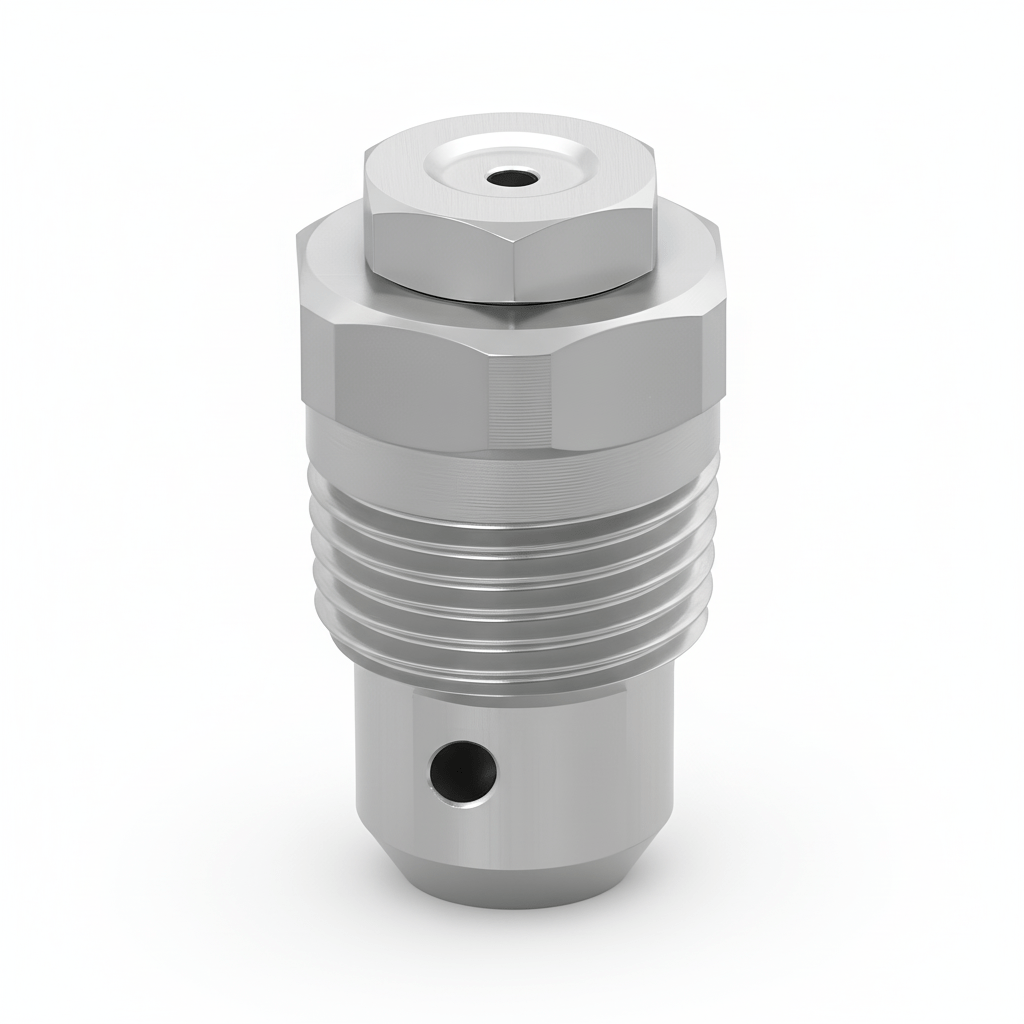

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPBD |

| Capacity Size | 60 |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | MALE (M) |

| Material Composition Filter | 303/304 stainless steel |

| Orifice Diameter. Nom. (mm) | 11.1 |

| Orifice Diameter. Nom. (in) | 0.438 |

| Inlet Connection Size (in.) | 1-1/2 |

| Hex Size (mm) | 50.8 |

| Inlet Dia. Nom. (mm) | 9.5+ |

| Inlet Dia. Nom. (in) | 0.375* |

Description

Product Overview

During cooling & quenching on a cement site, quality managers trust the NPBD-60-1-1/2-SS to deliver consistent spray coverage that protects equipment and materials. Installed with a 1-1/2-inch inlet, this nozzle's 303/304 stainless steel construction withstands corrosive conditions while maintaining structural integrity. Its precision hollow cone design ensures a uniform spray pattern, which optimizes cooling rates and minimizes thermal stress during processing. Operators observe improved process stability and reduced downtime due to the nozzle's reliable performance under demanding industrial conditions.

Applications

In cooling & quenching operations, the NPBD-60-1-1/2-SS provides uniform liquid distribution essential for controlling temperatures and preventing equipment damage. Additionally, its role in dust & pollution control helps maintain air quality standards by effectively suppressing particulate matter at the source.

Industries

The nozzle is favored across building materials, mining, and cement industries for its durability and precision spray characteristics that support critical process controls. Manufacturing & assembly and roofing sectors also utilize this nozzle to meet stringent operational requirements where corrosion resistance and consistent fluid delivery are necessary.