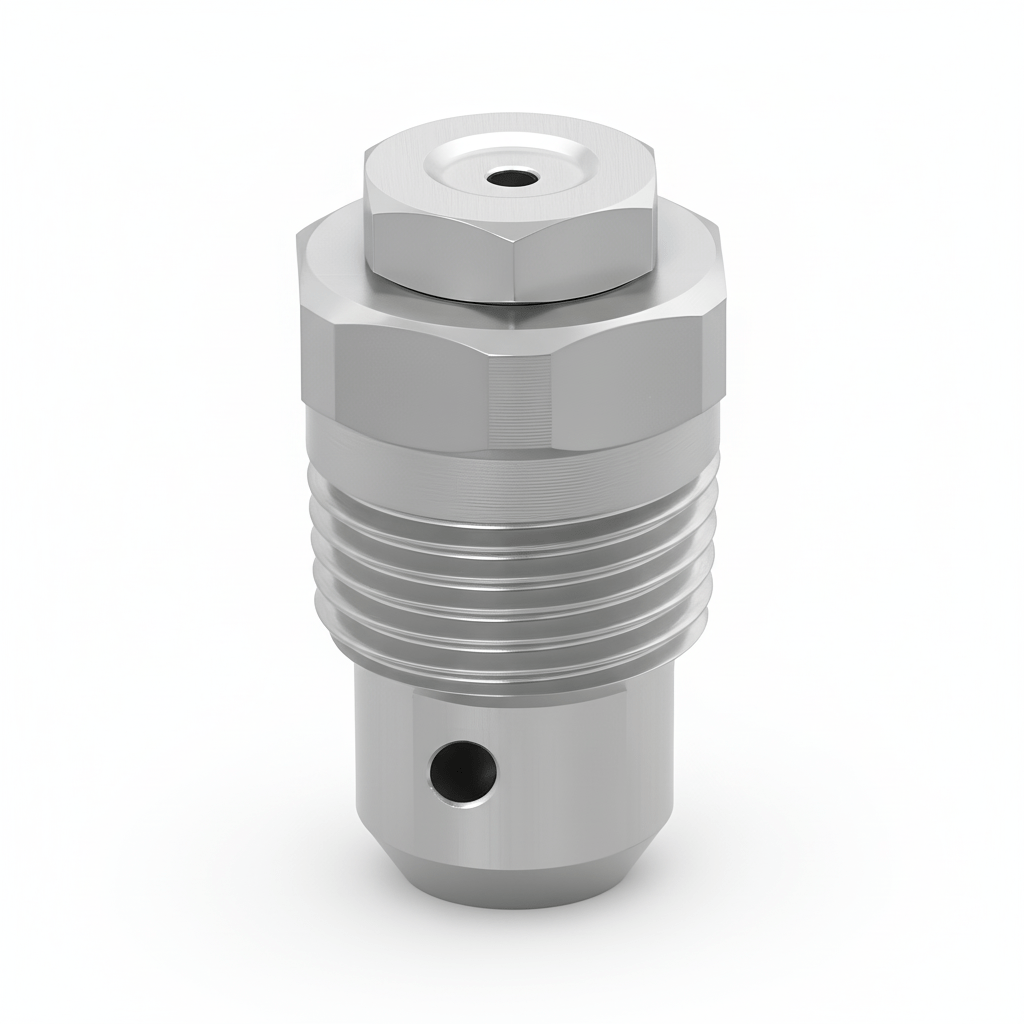

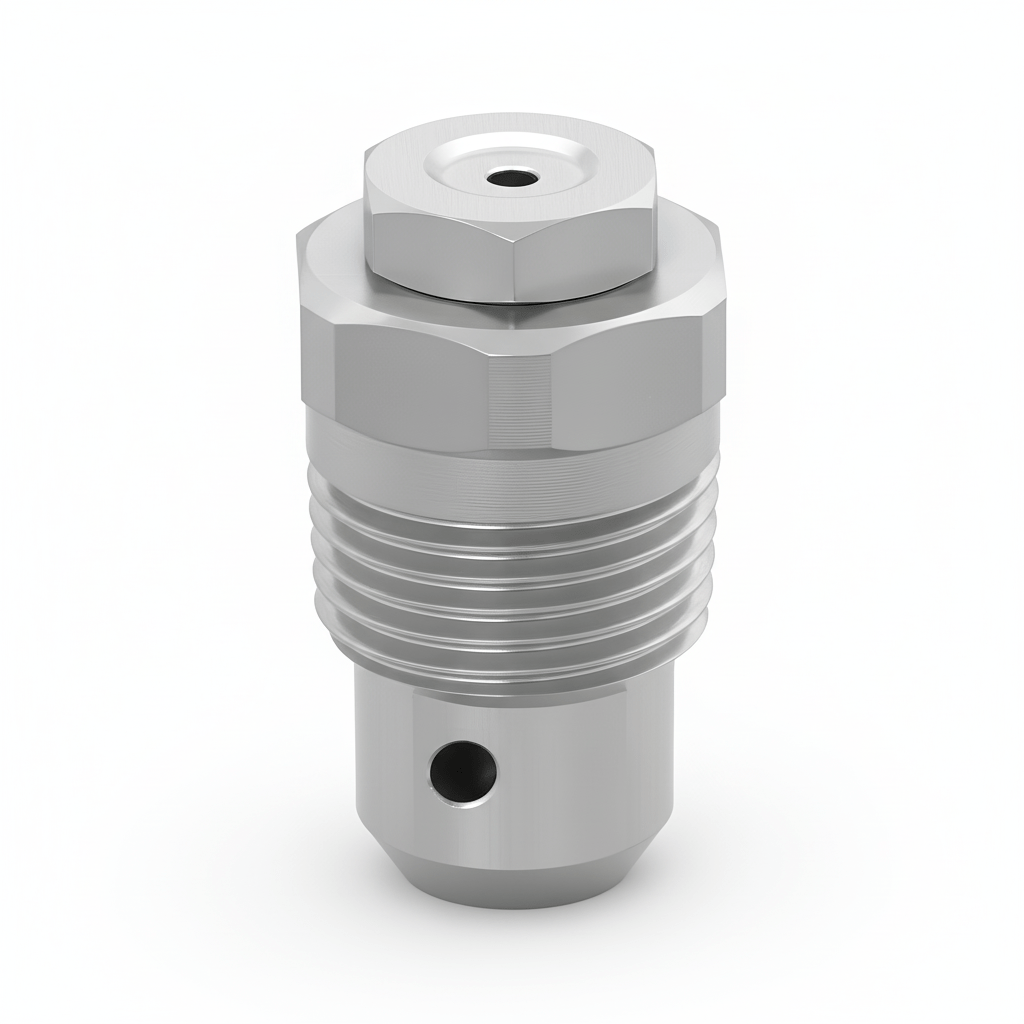

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPBD |

| Capacity Size | 5 |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | MALE (M) |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 3.2 |

| Orifice Diameter. Nom. (in) | 0.125 |

| Inlet Connection Size (in.) | 3/4 |

| Hex Size (mm) | 27 |

| Inlet Dia. Nom. (mm) | 3.6 |

| Inlet Dia. Nom. (in) | 0.141 |

Description

Product Overview

Inside the building materials line's cooling & quenching stage, a production technician relies on the NPBD-5-3/4-316 to deliver consistent and controlled spray coverage. Constructed from 316L stainless steel, the nozzle ensures durability against corrosion while maintaining operational integrity. With its precision hollow cone design and a 3/4 inch inlet, the nozzle creates a uniform atomized spray that optimizes cooling efficiency and reduces thermal stress on components. The technician monitors flow rates and spray angle to verify the nozzle meets process specifications and supports throughput goals.

Applications

In cooling & quenching processes, the nozzle provides stable and repeatable spray patterns that help maintain uniform temperature distribution across treated surfaces. The NPBD-5-3/4-316 also supports dust & pollution control by atomizing fluids in a way that suppresses airborne particulates and enhances environmental compliance.

Industries

Sectors such as building materials, mining, and cement industries incorporate this nozzle for its resistance to harsh conditions and steady spray performance. Additionally, roofing and manufacturing & assembly operations benefit from its ability to withstand corrosive environments while delivering precise fluid distribution.